Ilex Filtration Biodrum 20 +31384447366

11

Subject to typesetting and printing errors

7.3

Connecting a pump-fed system

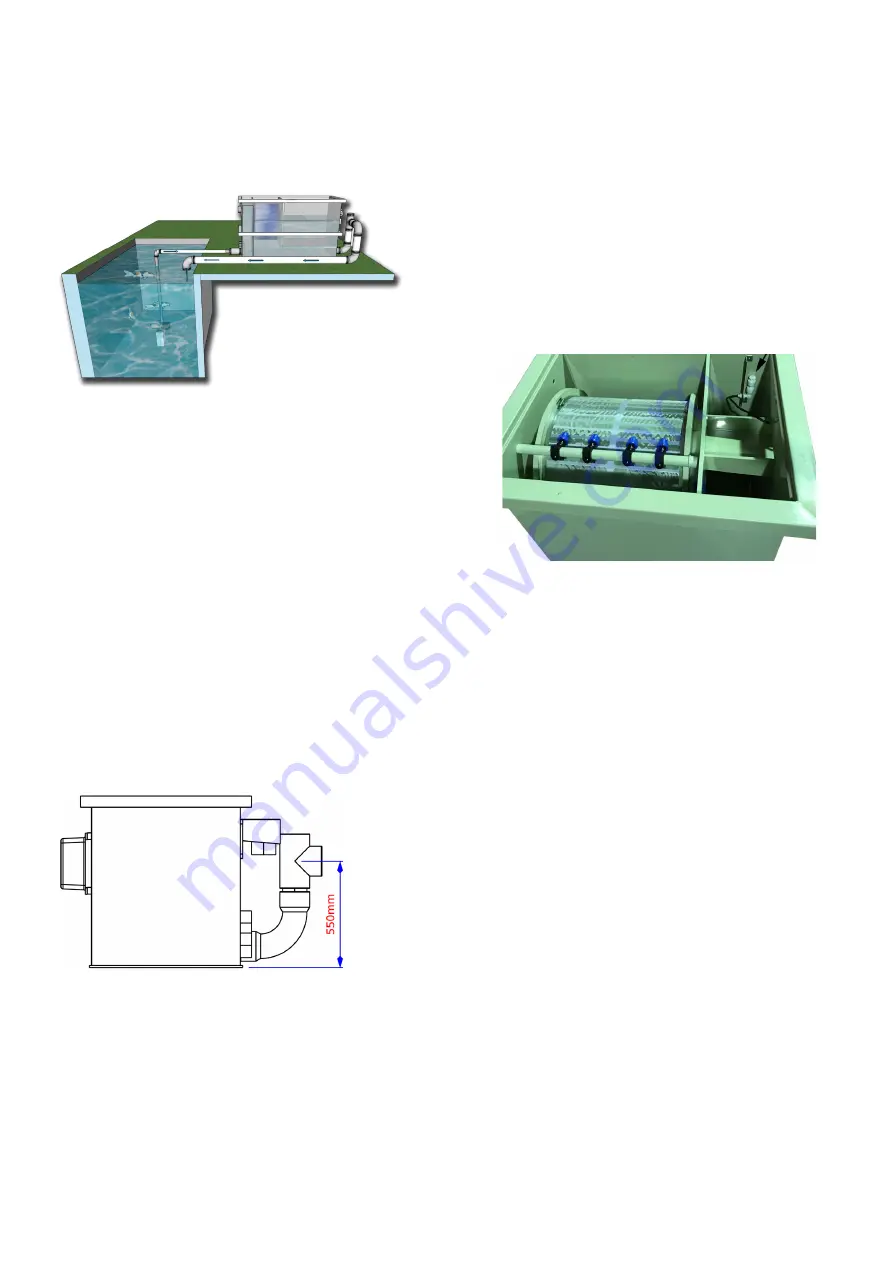

The SuperDrum Combi Bio can also be connected

as a pump-fed system: the water is pumped into

the filter by the pump. Openings that are unused

must be plugged.

7.3.1

Float installation

You must install the float in front of the drum section

for this (at the inlet). Additional holes have already

been provided in the housing for an easy installation.

Attention:

The float must be installed upside down because

the switching will also work in reverse order. If the

water now rises in front of the drum filter, it will be

contaminated and the rinse cycle must be

activated. If now the highest float goes up in the

upside down state, the system must switch off

because, if not, the water will flow directly to the

drains and your pump will be pumped dry via the

rinse duct. The safety float must therefore be

installed at the correct height in such a way that

the system switches itself off before the water

overflows into the rinse duct.

As extra protection, the 2 plugs of the top plugged

holes can be removed so that the water flows further

unfiltered during an emergency and there is no risk that

water is pumped directly into the rinse duct.

7.3.2 Connecting the pond return

The return to the filter must first go up to determine

the required height within the filter.

This should not be too low because of the present

biofilter material. It may not be too high either

because then the rinse frequency of the filter will

become too high.

The drum must also be aligned when in operation. A

rinse cycle must be started when the water level

difference before and after the drum is approximately

8-10 cm. Ensure that the vertical part stays open

when up so that there is no siphoning and that the

drum filter is suctioned dry because of it.

If you want to pump more water than 1x 110mm pipe

can handle at gravity, you need to make extra

passages. You can also connect the return to the

pond with a larger diameter pipe.

8.

Maintenance and cleaning

The SuperDrum Combi Bio requires little

maintenance. The following maintenance and

checking activities are, however, required to ensure

a good operation:

•

Check the correct operation of both floats on

a monthly basis.

•

Perform a manual rinse and check whether the

nozzles are spraying correctly on a monthly

basis. A nozzle can be clogged or limescale may

build up. The waste pump may also supply less

pressure. If required, clean the nozzles.

•

Clean the sieve element as required using a

strong acid (30-35% hydrochloric acid). A biofilm

or limescale may build up in due course, which

means that the rinse frequency will increase

significantly. Observe the safety instructions

when cleaning using acids. Use protective clothing

and safety goggles.

Technical Information

Capacity drum filter: 20 m3/uur

Effective space bio chamber: 110

Liter

Flush pump: Oase ProMax Garden Classic

3000

Pressure: 4.1 bar

P: 600W

Qmax: 3000 l/u

U: 220-230V/50-60Hz

Sieve mesh: 60

micron