Initial Operation

D8-3_EN

– V1.0

11/14

4.1.2

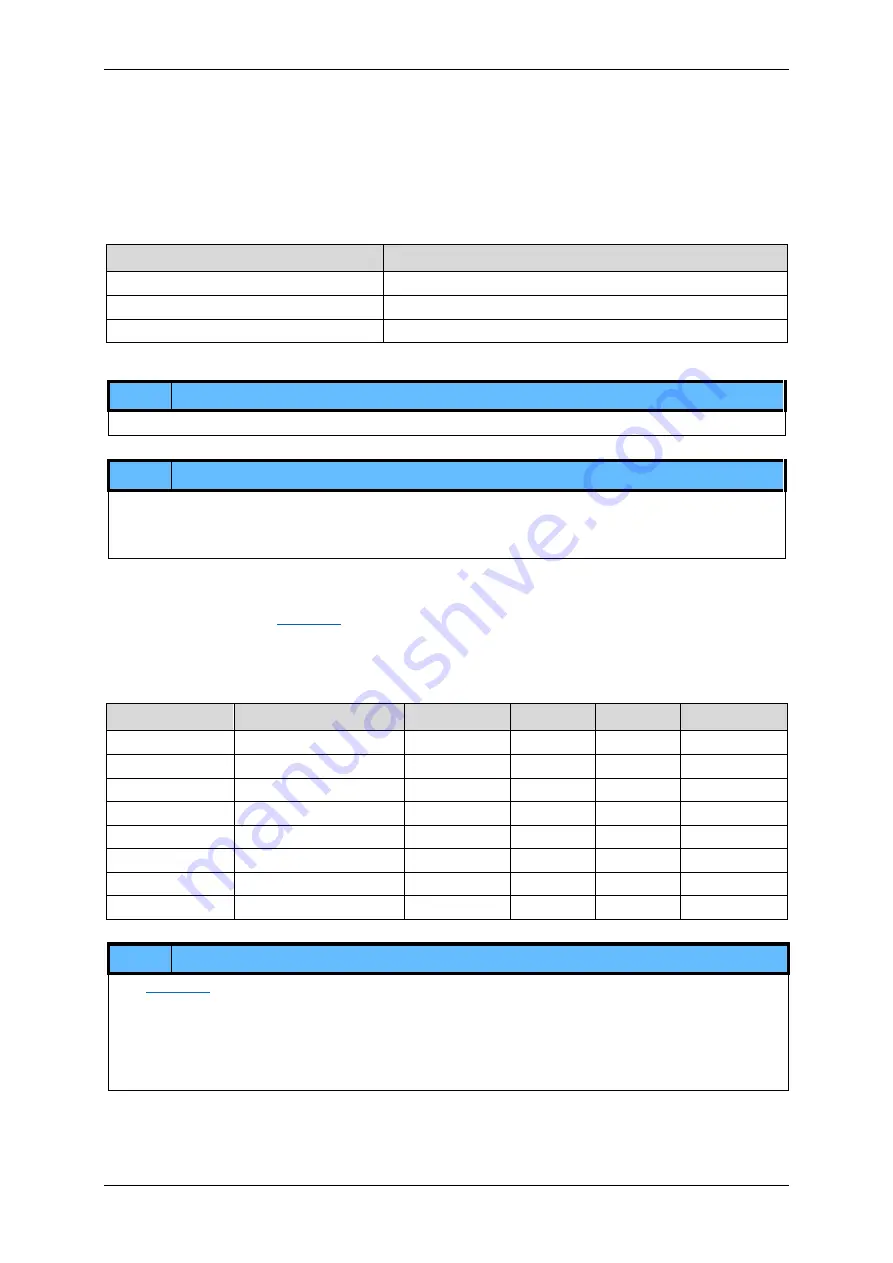

Standstill Current and Autotuning

If the enable signal is set but no motion command is present, the motor current set via switches SW1 to SW3 is reduced to 50%

(SW7 ON) or 90% (SW7 OFF) at standstill.

The auto-tuning function allows the motor controller to be optimally adapted to the connected motor. If this is performed, the

internal control parameters are tuned to ensure a high torque output even at high rpm, as well as generally quiet and low-

vibration operation.

If autotuning is started, the green status LED switches off for the duration of the parameter determination. Autotuning has been

successfully performed when the green status LED lights up again. This process takes approx. 3 seconds.

Standstill Current

SW7

50 % of preselected Motor Current-

ON

90 % of preselected Motor Current-

OFF

Start Autotuning

OFF

– ON – OFF within 1 second

NOTE

Autotuning can only be started if switch SW7 has been set to OFF for at least 1 second.

NOTE

Autotuning should always be performed when:

-

The motor control unit is used for the first time.

-

The motor controller's supply voltage changes

-

A different motor is connected to the motor controller

4.1.3

Micro-Stepping

If the motor controller is used in

(p.13), the desired micro step mode must be preselected by the combination of

switch SW4 to SW6 and SW 8.

By preselecting the micro steps per motor revolution, the precision, the resulting vibrations, and the noise of the motor can be

directly influenced.

The higher the micro steps, the better the precision and at the same time vibrations and noise are reduced to a minimum.

Micro Step

Step mode

SW4

SW5

SW6

SW8

200

1/1 Full Step

ON

ON

ON

ON

400

1/2 Step

OFF

ON

ON

ON

800

1/4 Step

ON

OFF

ON

ON

1600

1/8 Step

OFF

OFF

ON

ON

3200

1/16 Step

ON

ON

OFF

ON

6400

1/32 Step

OFF

ON

OFF

ON

12800

1/64 Step

ON

OFF

OFF

ON

25600

1/128 Step

OFF

OFF

OFF

ON

Note

(p.13) is used, the selection of the executed micro steps per motor revolution in the master controller and

in the motor controller must be the identical.

If, for example, 200 micro steps per motor revolution are set in the motor controller, but 400 micro steps per motor revolution

are set in the master controller, and the master controller issues the movement command for one motor revolution, the motor

will execute 2 revolutions.

The reason for this is that instead of the 200 pulses expected by the motor controller for one motor revolution, 400 pulses

were now emitted by the master controller and these were converted into 2 motor revolutions.