-10-

www.igmtools.com

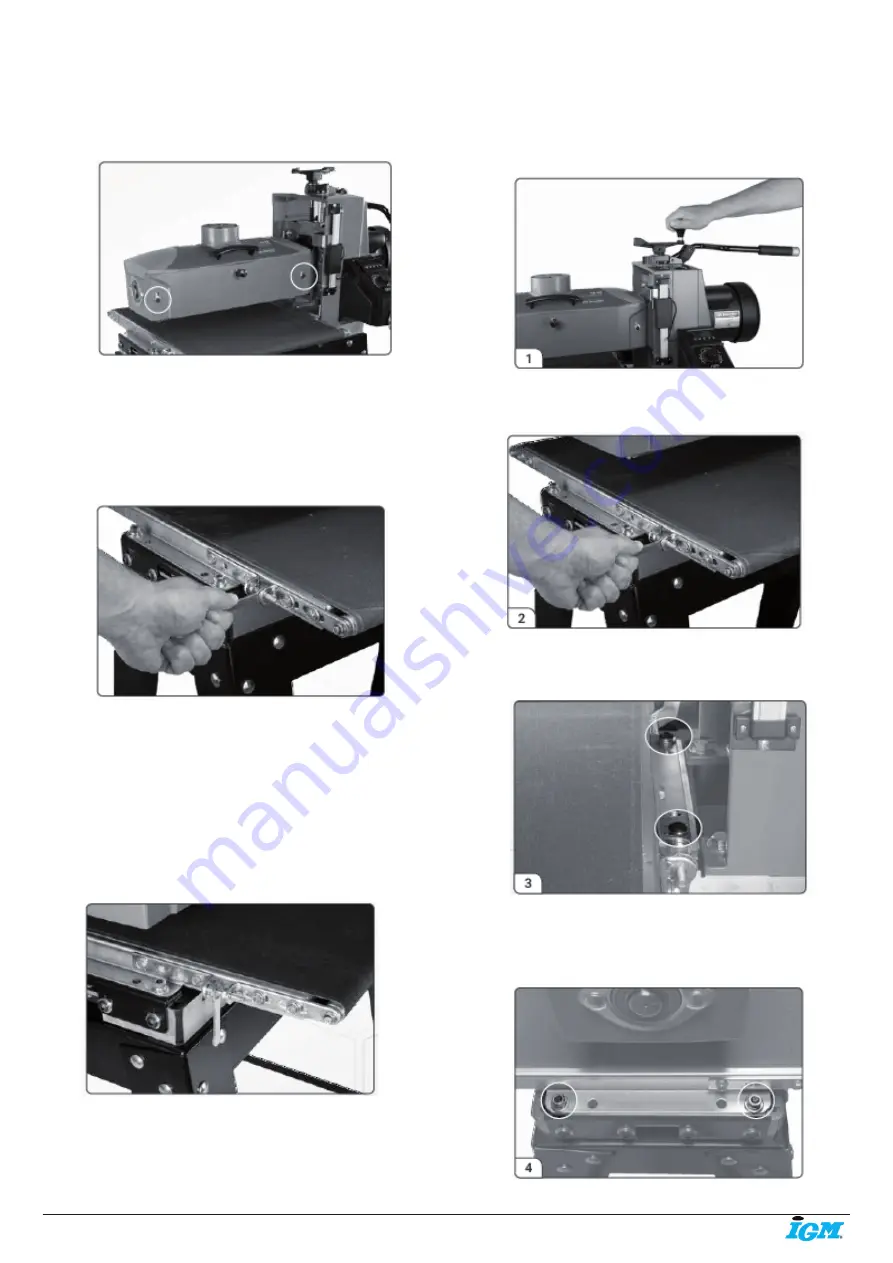

holding the tension roller brackets (2 per side; front and back).

2. Have abrasive wrapped on the drum.

3. With the machine unplugged, lower sanding drum until it rests on

conveyor belt.

4. Raise drum 2 to 3 revolutions.

5. Tighten the four socket head screws.

6. Raise the drum up, off of the conveyor belt.

7. Set the drum on the proper sanding height.

Fig. 39

Conveyor Belt Tension

Insufficient belt tension will cause slippage of conveyor belt on the drive

roller. The conveyor belt is too loose if it can be stopped by placing your

hand directly on the conveyor belt.

Excessive belt tension can result in bent rollers, premature wearing of the

bronze bushings or conveyor belt.

To adjust the conveyor belt, first adjust the take-up screw nut on both

sides of the conveyor to obtain approximately equal tension on both sides.

Fig. 40

Conveyor Belt Tracking

Belt tracking adjustments are made while the conveyor belt is running.

After the proper belt tension is obtained, turn the conveyor on and set it at

the fastest speed setting. Watch for a tendency of the conveyor belt to drift

to one side of the conveyor.

To adjust the belt tracking, tighten the take-up screw nut on the side the

belt is drifting toward, and loosen the take-up screw nut on the opposite

side.

Adjusting the take-up screw nuts does not affect the belt tension.

Note: Adjust the take-up screw nuts only 1/4 turn at a time. Allow the

belt to react to the adjustments before proceeding further. Avoid over-

adjustments.

Fig. 41

8. Maintenance

Monthly Maintenance

• Lubricate conveyor bushings and check for wear.

• Lubricate with a dry lubricant spray all of the moving parts.

• Clean dust from conveyor belt.

• Check all set screws for tightness.

• Clean drum and abrasives if necessary.

Replacing Conveyor Belt

To replace the conveyor belt, the conveyor assembly must be removed

from the machine.

Unplug the machine from the power source!

1. Raise the drum carriage to its highest position. Unplug main drive motor

from receptacle on the machine.

Fig. 42

2. Loosen the conveyor take-up screws to relieve belt tension and slide

the drive roller fully inward.

Fig. 43

3. Remove the two hex bolts on the inboard (right) side that attach the

conveyor assembly to the base.

Fig. 44

4. Remove the two nuts and washers from outboard (left) side. Lift the

conveyor and remove it from the sander. Set conveyor on motor side.

Avoid tearing the belt on any edges underneath the conveyor bed during

removal. Reverse the procedure for re-installation.

Fig. 45

Содержание 71632

Страница 66: ...66 www igm cz 16 32 HEAD ASSEMBLY...