www.igmtools.com

6

Operating manual EN

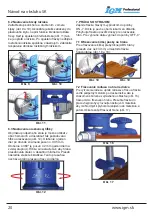

6.2 Adjusting the bearing stop

Push the pin upwards and rotate it in the arrow

direction (fig.9 and fig.10). Once the pin is pushed

into the plastic housing, it does not fulfill its function

as a stop for the bit’s bearing. When the pin is

lowered back, it rests on the bearing. After starting

the trimmer, the bearing will not spin together with

the machine. This way, you will prevent burning of

the workpiece with the spinning bearing.

fig. 9

fig. 10

fig. 11

6.3 Calibrating the trimming depth

The supporting table sleeve can be rotated in

both directions to achieve the desired trimming

depth (fig.12). One notch around the perimeter is

0,05mm. When rotated by 360° it shifts by 2mm

(on notch on the vertical scale). Set the depth, so

that the edge is beyond the workpiece by tenths of

a millimeter. You can later align this discrepancy

with the radius scraper. This overlap secures that

the router does not damage your workpiece.

fig. 12

7. OPERATION

Turn the trimmer on by placing the switch in the

ON “1” position. Hold it firmly with both hands by

the handles. Move the trimmer along the board to

trim edges. To turn it off, by placing the switch into

an OFF “0” position.

7.1 Trimming of wide tape on the edge

To trim a wider excess ABS edge (overlap more than

3mm) place the trimmer horizontally (fig.18 and 19.)

fig. 18

fig. 19

7.2 Trimming a radius on the edge

To square up a banded edge, affix a router bit into

the trimmer. Move the trimmer into operational

position, align the trimmer with the material

to allow for a smooth drive into the material.

Lead the router bit with the help of a supporting

table along the workpiece as depicted in the

red highlighted area (fig.16). Now you can start

trimming the edge (fig.17)

fig. 16

fig. 17