3

UK

Preliminary note

• An instruction is indicated by “►”:

Example: ► Check whether the unit operates correctly.

• A reaction to the action is indicated by ">":

Example: > LED 9 lights.

1 Safety instructions

• Please read the product description prior to set-up of the unit� Ensure that the

product is suitable for your application without any restrictions�

• The unit conforms to the relevant regulations and EC directives�

• Improper or non-intended use may lead to malfunctions of the unit or to un-

wanted effects in your application�

• That is why installation, electrical connection, set-up, operation and mainte-

nance of the unit must only be carried out by qualified personnel authorised by

the machine operator�

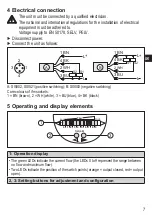

For units with cULus approval and the scope of validity cULus:

The device shall be supplied from an isolating transformer having a secondary

Listed fuse rated as noted in the following table�

Overcurrent protection

Control-circuit wire size

Maximum protective device rating

Ampere

AWG

(mm

2

)

26

(0�13)

1

24

(0�20)

2

22

(0�32)

3

20

(0�52)

5

18

(0�82)

7

16

(1�3)

10