FS-2/FS-2N monitors have a one channel design. By means of an electrical

connection of the outputs of two or several units to achieve a redundant cir-

cuit, they can also be used for safety tasks. The applicable technical standards

must be adhered to.

3. Operating principle

(setting example)

To avoid the differential pulses adding up to the limit value/switch point if an

uncritical slip occurs several times over a long period they are regularly reset by the

adjustable reset time.

Only in case of critical slip or blocking is the allowed number of differential pulses

exceeded within the reset time and the monitor switches.

Differential pulses are generated by:

• Blocking = maximum rotational speed difference in few ms

• Overload = small rotational speed difference over a longer period.

Setting example

The length of the reset time also depends on the allowed rotational speed differ-

ence and the data of the clutch.

In principle it can be said:

The monitoring sensitivity increases when the reset time is prolonged for an identi-

cal number of differential pulses.

MONITOR

FS-2 / FS-2N

PAGE

21

ENGLISH

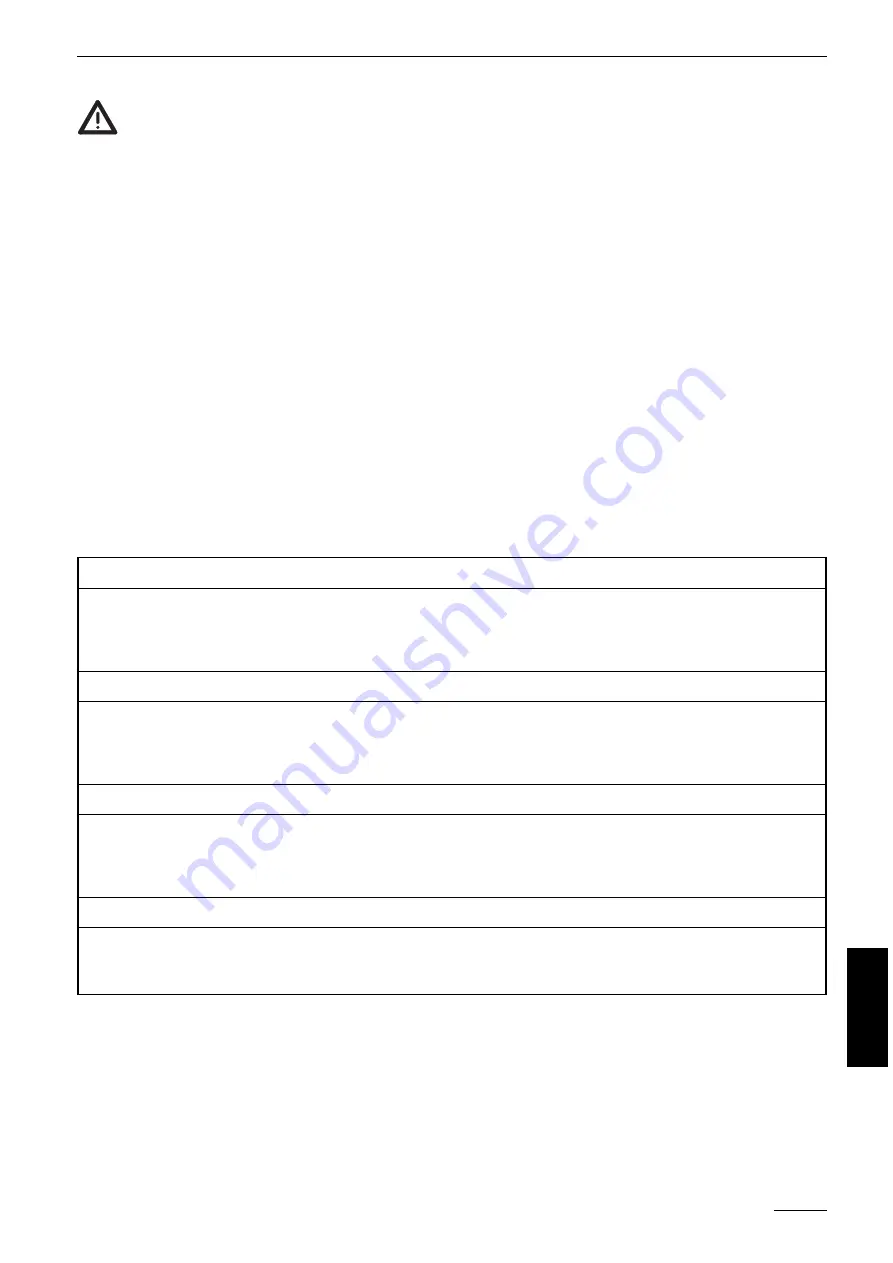

System parameters for synchronous running

Rotational speed of the drive:

1500 RPM

Switching cam:

2 per revolution on the drive and power take-off side

Pulses for synchronous running:

3000 pulses/min at both inputs (= 50 pulses/s),

Pulse difference:

0 RPM

Power take-off side blocked

Rotational speed of the drive:

1500 RPM

Rotational speed of the power take-off side: 0 RPM

Rotational speed difference:

1500 RPM

Pulse difference:

3000 pulses/min (= 50 differential pulses/s)

Drive side overload

Rotational speed of the drive:

1500 RPM

Rotational speed of the power take-off side: 1440 RPM

Rotational speed difference:

60 RPM

Pulse difference:

120 pulses/min (= 2 differential pulses/s)

Parameter values for overload and blocking of the power take-off side

Number of the differential pulses (SPx)

2 pulses/s

Reset time (CTx)

1,0 s

(or a multiple, e.g. 6 differential pulses in 3.0 s)