QUICK START GUIDE

EPC – THE LEADER IN GaN TECHNOLOGY |

| COPYRIGHT 2019 | | 3

EPC9034

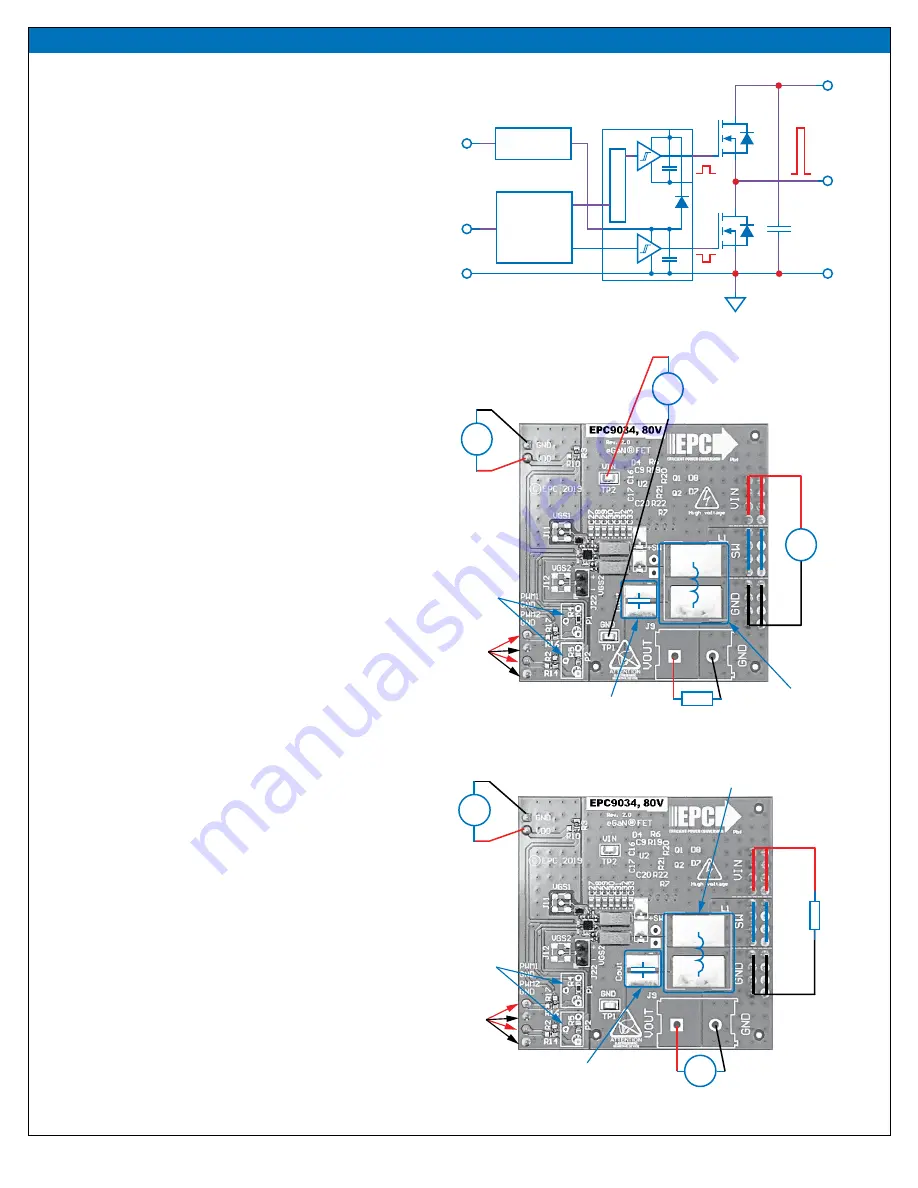

Figure 2: Buck configuration

Figure 3: Boost configuration

Figure 1: Block diagram of EPC9034 development board

7.5 – 12 V

DC

32 V

DCmax

V

DD

supply

(Note polarity)

V

Main

supply

(Note polarity)

Output Capacitor

Output Inductor

Main voltage measurement

(HIGH VOLTAGE!)

DC load

Dead-time adjust

Control

signal

inputs

+

+

V

Boost Converter configuration

Warning: Never operate the boost converter mode without a load

as the output voltage can increase beyond the maximum ratings.

1. The inductor (L

1

) and input capacitors (labeled as C

out

) can

either be soldered onto the board, as shown in figure 3, or

provided off board. Anti-parallel diodes can also be installed

using the additional pads on the right side of the EPC2021

FETs.

2. With power off, connect the input power supply bus to V

OUT

(J9, Pin-1) and ground / return to GND (J9, Pin-2), or externally

across the capacitor if the inductor L

1

and C

out

are provided

externally. Connect the output voltage (labeled as V

IN

, J5, J6)

to your circuit as required, e.g., resistive load.

3. With power off, connect the gate drive supply to V

DD

(J1,

Pin-1) and ground return to GND (J1, Pin-2 indicated on the

bottom side of the board).

4. With power off, connect the input PWM control signal to

PWM1 (J2, Pin-1) and ground return to any of GND J2 pins

indicated on the bottom side of the board. Note that the

bottom FET gate drive signal is inverted with regard to

PWM1. It is also possible to use separate input PWM signals

by removing R2 and R17 and installing 0 Ω jumpers for R14

and R16.

5. Turn on the gate drive supply – make sure the supply is

between 7.5 V and 12 V.

6. Turn on the controller / PWM input source.

7. Making sure the output is not open circuit, and the input

supply voltage is initially 0 V, turn on the power and slowly

increase the voltage to the required value (do not exceed

the absolute maximum voltage). Probe switching node to

see switching operation.

8. Once operational, adjust the PWM control, bus voltage, and

load within the operating range and observe the output

switching behavior, efficiency and other parameters.

Observe device temperature for operational limits.

9. For shutdown, please follow steps in reverse.

7.5 – 12 V

DC

V

DD

supply

(Note polarity)

Input Capacitor

Input Inductor

Dead-time adjust

Control

signal

inputs

+

32 V

DCmax

DC load

V

Main

supply

(Note polarity)

+

Lev

el shif

t

V

DD

V

IN

Q

1

Q

2

C

Bypass

PWM

GND

Gate drive

regulator

Gate driver

Output

PGND

Logic and

dead-time

adjust