64

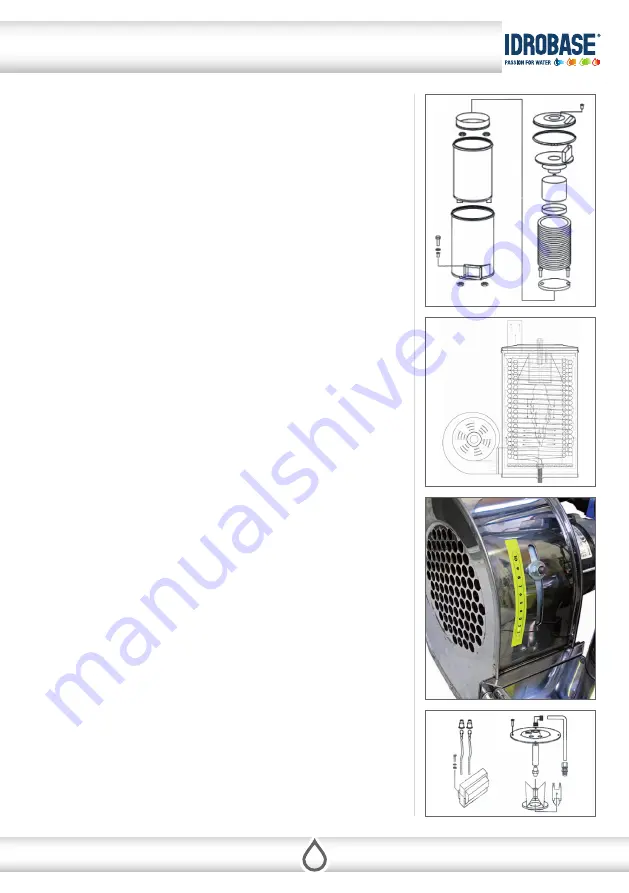

This type of heater provides the maximum efficiency in a limited space while maintai-

ning an almost unique feature, as a matter of fact, thanks to a ventilated chamber and

another chamber that acts as insulation, is able to maintain very low outside tempera-

tures during full operation.

All the metal parts subject to the extremely high combustion temperatures are made

of stainless steel. The coil creates fume passages to achieve the best possible combu-

stion without sacrificing efficiency.

Heater cleaning

Remove the heater cover and clean the soot from the inside, remove the heating coil

and clean it with a pressure washer to remove, also in this case, any soot attached to it.

Perform this operation only if necessary.

HEATER ADjUSTMENT

Adjustment made by the manufacturer is valid in most cases on average use condi-

tions. There are some factors that may require a variation of the pre-set adjustment

done by the manufacturer.

Low temperature of fuel and air

.

Decreasing of temperature causes an increase of fuel viscosity (viscosity is fuel resi-

stance when it is moved); it follows that you get a poor atomization, and then a non-

optimal combustion and, in some cases, ignition problems. Furthermore, paraffin that

can be found in the fuel, with low temperature, can crystallize, causing the obstruc-

tion of filters, of small pipes and nozzle. The most suitable action is not to change

the adjustment of combustion but, rather, is to protect the pressure washer from cold

weather.

Altitude or high air temperature

.

Burner fan provides combustion air by volume (m3); with high air temperature and/or

high altitude, weight of the air for each m3 (specific weight) is lower, then percentage

of oxygen in the same will be lower too, which for its weight it chemically combines by

percentages, always referring to its weight, with fuel carbon and hydrogen: there will

be then ignition lacking in air.

If variables above mentioned are of little importance, you can compensate for them by

slightly increasing amount of air sucked by the fan, through its opening, or as alterna-

tive, by decreasing fuel pressure and thus the flow. This operation reduces, in general,

also combustion noise level. Pressure decrease, however, in addition to a negligible

decrease of the water temperature, causes, especially if combustion is excessively vi-

scous, a poor atomizing and combustion and then ignition problems. To remedy to

what mentioned above, it will be better to replace the nozzle with a similar one but

with a flow immediately lower, leaving unchanged the pressure. Normally, pressure of

fuel to nozzle is calibrated on 9.5 bar + / -0.5. Varying flow rate of the fuel, you will have

to regulate air flow too. Air should not be too much, because while it gets warm, it re-

moves calories from the combustion disturbing, inside pre-combustion cone, ignition

and proper mixing with the fuel.

9 - MAINTENANCE

Cop

yrigh

t ©2016 I

dr

obase G

roup

. A

ll righ

ts r

eser

ved

.