18

Classic

LXRS, RS

-

Propane Installation

SERVICING

SER

VICING

Heat Input / Setting Pressure

After each occasion of servicing, reference should be

made to Table 2, which quotes details of the rated output,

with the related burner setting pressure and the heat input.

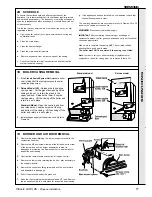

35 PILOT BURNER CHECKING

33 CLEANING THE BURNER & PILOT

ASSEMBLY.

Refer to Frame 31 for illustration of the procedure below.

1.

Brush off any deposits that may have fallen onto the

burner head, ensuring the flame ports are unobstructed,

and remove any debris that may have collected.

Note.

Brushes with metallic bristles MUST NOT be used.

2.

The main burner injector can be removed, checked and

cleaned or replaced as required. Ensure an approved

jointing compound is used, sparingly.

3.

Inspect the pilot burner, thermocouple and spark

electrode; ensure they are clear and in good condition.

Check that:

a.

The pilot burner injector is not blocked or damaged

(refer to Frame 39 for removal details).

b.

The pilot burner is clean and unobstructed.

c.

The spark electrode is clean and undamaged.

d.

The spark lead is in good condition and securely

connected.

e.

The spark gap is correct. Refer to Frame 35.

f.

The thermocouple tip is not burned or cracked.

g.

The position of the thermocouple relative to the pilot

burner is correct. Refer to Frame 35.

h.

The thermocouple terminal at the gas valve is clean.

4.

Re-assemble the burner / air box assembly in reverse

order. Ensure that the burner tab is correctly located.

Refer to Frame 31.

Note.

The pilot shield is positioned around the pilot assembly

bracket and is located by the electrode retaining nut.

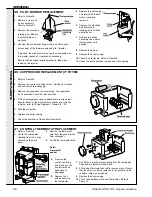

Detail of pilot burner flame

1.

Turn on the gas supply.

2.

Light the pilot (refer to Frame 25) and check that the

pilot flame envelopes the tip of the thermocouple

and is

approximately 25

mm (1") long. The

pilot is factory set

to maximum and

no further

adjustment should

be necessary.

However, if the

pilot flame

appears small,

check the pilot

injector. Refer to

Frame 39.

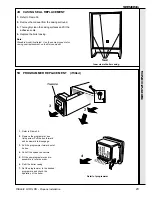

Re-assemble in reverse order to that shown in Frames 30

to 33.

1.

Refit the flue baffles and retain with the spring clips.

2.

Refit the collector hood, replacing any damaged or

deteriorating gaskets.

Note.

Ensure rear

vertical

hood retaining screws are tightened

before

rear horizontal screws and the tie rods are located into

the holes in the base of the combustion chamber

3.

Refit the burner and air box assembly. Ensure the burner

tab is correctly located (refer to Frame 31).

4.

Refit the burner support.

5.

Refit the control box assembly.

6.

Turn on the gas supply.

7.

Ensure the sightglass in the boiler casing is clean and

undamaged .

8. Deluxe Model (LX)

- Refit the boiler casing. Tighten the 2

lower captive casing screws. Push the sliding catch in and

lower the glass fascia to the closed position. Tighten the

upper captive casing screw.

Standard Model

- Refit the boiler casing and tighten the 3

captive screws. Close the pod door.

9.

Inspect the visible casing seal for correct fit.

10. Deluxe Model (LX)

- Push the sliding catch in and lower

the glass fascia to the closed position.

Standard Model -

Close the controls pod door.

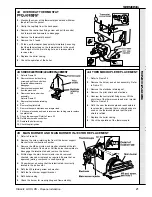

34 RE-ASSEMBLY

32 CLEANING THE FLUEWAYS

1.

Remove the collector hood by undoing the front tie rod

nuts and releasing the tie rods from the combustion

chamber. Withdraw the rods.

2.

Remove the 4 collector hood retaining screws and

washers.

3.

Unclip and remove the flue baffles from the heat

exchanger.

Note.

There are no flue baffles in the RS 255P.

4.

Remove all loose deposits from the heat exchanger,

particularly between the fins, using a suitable brush.