603GC SHOP MANUAL

75

Copyright © May 24, 2006 ICS, Blount Inc.

24

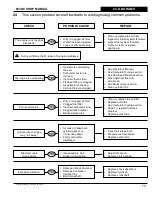

This section provides several flowcharts to aid diagnosing common problems.

CHECK

POSSIBLE CAUSE

REPAIR

The engine runs rough at

all speeds.

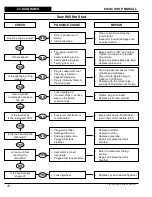

The engine is overheating.

•

Operator is overworking

the saw.

•

Carburetor mixture is

too lean.

•

Incorrect fuel/oil ratio.

•

Flywheel fins are clogged.

•

Air deflector is missing.

•

Cylinder fins are clogged.

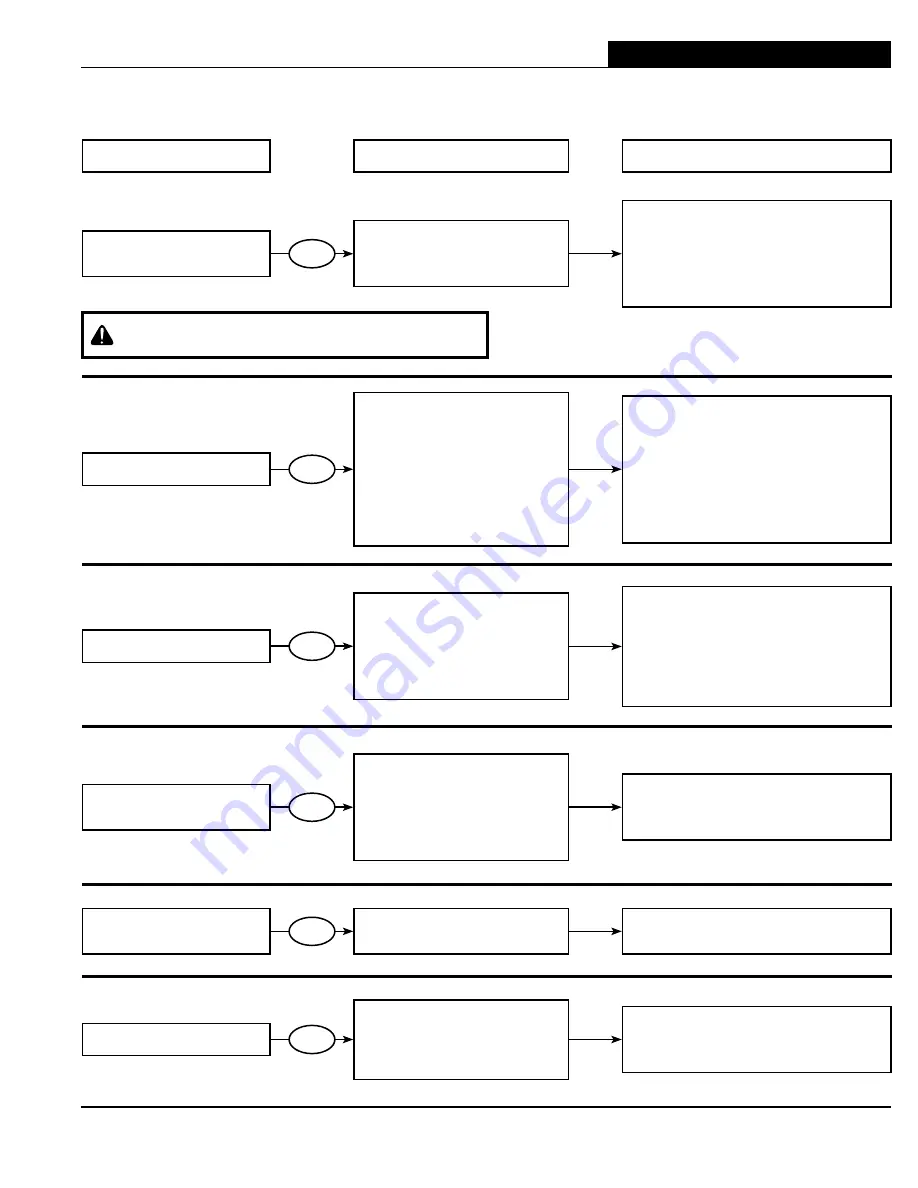

Poor acceleration.

•

Dirty or clogged air filter.

•

Clogged fuel filter.

•

Incorrect carburetor tune.

•

Plugged tank breather.

•

Blocked pulse tube.

Uneven idle or engine

may “run away”.

•

Air leak at intake boot,

cylinder gasket, or

crankcase gasket.

•

Faulty carburetor

diaphragm.

Diamond chain

moves at idle.

•

Idle speed too high.

•

Broken clutch spring.

Excessive vibration.

YES

•

Damaged shock absorber.

•

Damaged or broken

flywheel fins.

•

Bent crankshaft.

•

Replace shock absorbers.

•

Replace flywheel.

•

Replace crankshaft.

•

Adjust idle speed.

•

Replace clutch spring.

YES

•

Inspect air intake boot.

•

Pressure test crankcase.

•

Replace carburetor.

YES

•

Clean or replace the air filter.

•

Replace fuel filter.

•

See Carburetor Tuning section.

•

Repair or replace fuel tank

breather.

•

Replace pulse tube.

YES

•

See Operator’s Manual.

•

See Carburetor Tuning section.

•

See Saw Specifications section.

•

Clean flywheel fins with

wire brush.

•

See Starter Cover section.

•

Clean cylinder fins.

YES

•

Dirty or clogged air filter.

•

Water has been ingested.

•

Loose or dirty spark plug.

•

Clean or replace the air filter.

•

Inspect air intake sysetm for water.

•

Inspect fuel system for water.

•

Tighten, clean, or replace

spark plug.

YES

A dirty air filter is the # reason for engine problems.

24. DIAGRAMS

Содержание 603GC

Страница 1: ...603GC Gas Utility Saw Shop Manual...

Страница 2: ......

Страница 84: ...603GC SHOP MANUAL 82 Copyright May 24 2006 ICS Blount Inc...