6

Specifications subject to change without notice.

516 01 3604 04

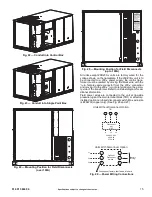

Fig. 3 — Service Clearance Dimensional Drawing

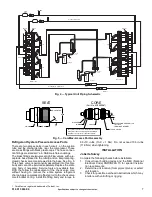

REFRIGERATION SYSTEM COMPONENTS

Each heat pump refrigeration system includes a compres

-

sor, accumulator, reversing valve, dual-function outdoor coil

with vapor header check valve, cooling liquid line with a filter

drier and a check valve, dual-function indoor coil with a va

-

por header check valve, and heating liquid line with a check

valve and a strainer. Size 120 units have two compressor-

circuits. See Fig. 4 for typical unit piping schematic (4-row

indoor coil with two compressor-circuits is shown).

Dual-function outdoor and indoor coils are designed to pro

-

vide parallel coil circuits during evaporator-function opera

-

tion and converging coil circuits during the condenser-func

-

tion operation.

Reversing Valve and Check Valve Position

Troubleshooting Refrigerant Pressure Problems

and Check Valves

Refer to Fig. 4 and the Cooling Mode and Heating Mode ta

-

NOTE: Unit not designed to have overhead obstruction. Contact Application Engineering for guidance on any application planning overhead

obstruction or for vertical clearances.

LOCATION

DIMENSION

CONDITION

A

48-in. (1219 mm)

18-in. (457 mm)

18-in. (457 mm)

12-in. (305 mm)

Unit disconnect is mounted on panel

No disconnect, convenience outlet option

Recommended service clearance

Minimum clearance

B

42-in. (1067 mm)

36-in. (914 mm)

Special

Surface behind servicer is grounded (e.g., metal, masonry wall)

Surface behind servicer is electrically non-conductive (e.g., wood, fiberglass)

Check sources of flue products within 10-ft (3 m) of unit fresh air intake hood

C

36-in. (914 mm)

18-in. (457 mm)

Side condensate drain is used

Minimum clearance

D

42-in. (1067 mm)

36-in. (914 mm)

Special

Surface behind servicer is grounded (e.g., metal, masonry wall, another unit)

Surface behind servicer is electrically non-conductive (e.g., wood, fiberglass)

Check for adjacent units or building fresh air intakes within 10-ft (3 m) of this unit’s flue outlet

C

D

A

B

Table 2 — Cooling Mode (Each Circuit)

COMPONENT

STATUS/POSITION

Reversing Valve

Energized

Check Valve A

Closed

Check Valve B

Open

Check Valve C

Closed

Check Valve D

Open

Table 3 — Heating Mode (Each Circuit)

COMPONENT

STATUS/POSITION

Reversing Valve

De-Energized

Check Valve A

Open

Check Valve B

Closed

Check Valve C

Open

Check Valve D

Closed

Table 4 — Defrost Mode

COMPONENT

STATUS/POSITION

Defrost Thermostat

Closed

Outdoor Fan(s)

Off

Reversing Valve

Energized

Check Valve A

Closed

Check Valve B

Open

Check Valve C

Closed

Check Valve D

Open