SERVICE AND TECHNICAL SUPPORT MANUAL

Gas Furnace: N9MSE

Specifications subject to change without notice.

440 04 4401 03

17

14. Reinstall 2 screws securing blower assembly to blower

deck.

15. Reconnect blower leads to furnace control. Refer to

furnace wiring diagram, and connect thermostat leads if

previously disconnected.

NOTE

: Be sure to attach ground wire and reconnect blower

harness plugs to blower motor.

ELECTRICAL OPERATION HAZARD

Failure to follow this warning could result in personal

injury or death.

Blower door switch opens 115

−

V power to control. No

component operation can occur unless switch is closed.

Caution must be taken when manually closing this

switch for service purposes.

!

WARNING

16. Downflow or horizontal furnaces with vent pipe through

furnace only:

a. Install and connect short piece of vent pipe inside

furnace to existing vent.

b. Connect vent connector to vent elbow.

17. Turn on electrical supply. Manually close blower door

switch. Use a piece of tape to hold switch closed. Check

for proper rotation and speed changes between heating

and cooling by jumpering R to G and R to Y on furnace

control thermostat terminals. If outdoor temperature is

below 70

_

F (21

_

C), turn off circuit breaker to outdoor unit

before running furnace in the cooling cycle. Turn outdoor

circuit breaker on after completing cooling cycle. (See

Figure 4

)

NOTE

: If R

−

W/W1 thermostat terminals are jumpered at the

time blower door switch is closed, blower will run for 90 sec

before beginning a heating cycle.

a. Perform component self

−

test as shown at the bottom

of the SERVICE label, located on the blower door.

b. Verify blower is rotating in the correct direction

18. If furnace is operating properly, RELEASE BLOWER

DOOR SWITCH. Remove any jumpers or reconnect any

disconnected thermostat leads. Replace blower door.

19. Turn on gas supply and cycle furnace through one

complete heating cycle. Verify the furnace temperature

rise as shown in Adjustments Section. Adjust

temperature rise as shown in Adjustments Section.

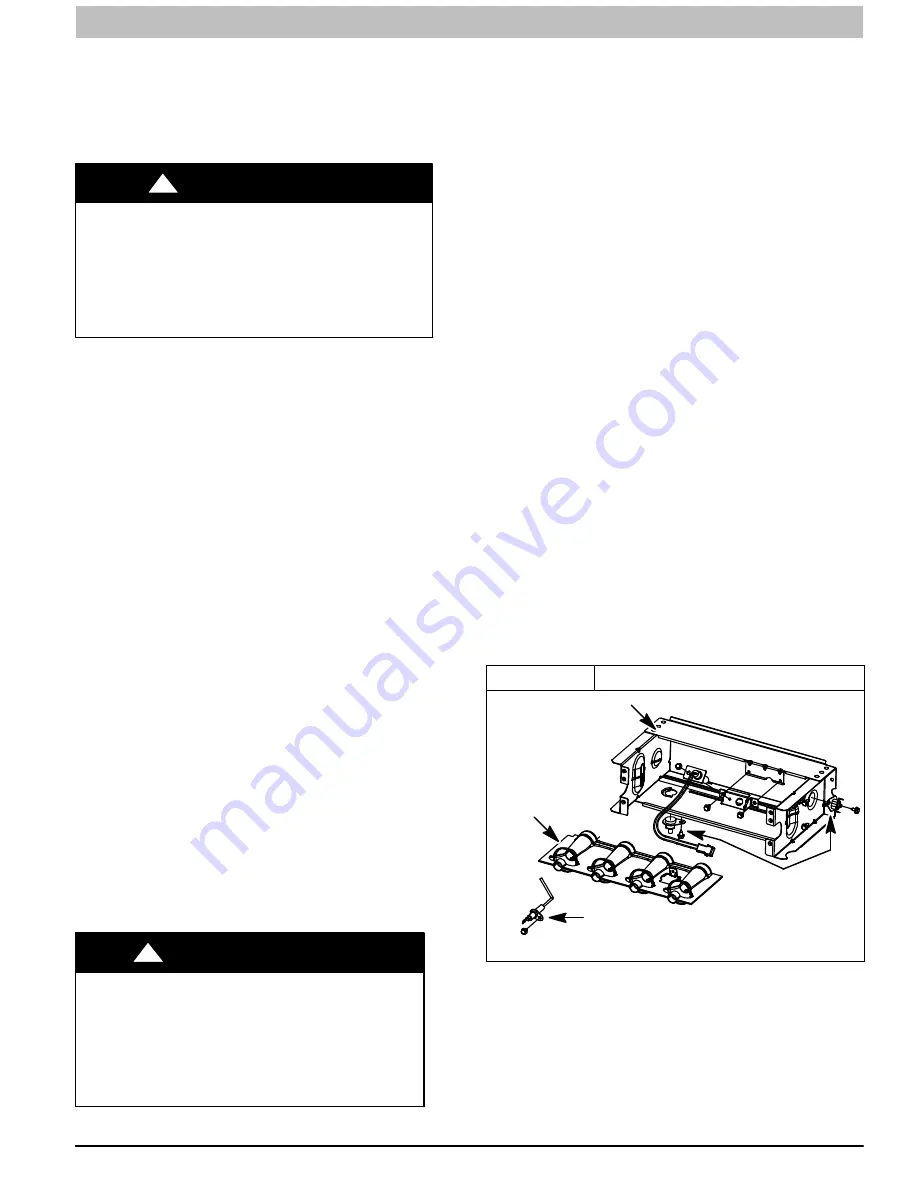

Cleaning Burners and Flame Sensor

The following items must be performed by a qualified service

technician. If the burners develop an accumulation of light dirt

or dust, they may be cleaned by using the following procedure:

NOTE

: Use a back-up wrench on the gas valve to prevent the

valve from rotating on the manifold or damaging the mounting

to the burner assembly.

ELECTRICAL SHOCK AND FIRE HAZARD

Failure to follow this warning could result in personal

injury, death, and/or property damage.

Turn off the gas and electrical supplies to the furnace

and install lockout tag before performing any

maintenance or service. Follow the operating

instructions on the label attached to the furnace.

!

WARNING

Refer to

Figure 9

.

1. Disconnect power at external disconnect, fuse or circuit

breaker.

2. Turn off gas at external shut-off or gas meter.

3. Remove control door and set aside.

4. Turn electric switch on gas valve to OFF.

5. Disconnect the gas pipe from gas valve and remove pipe

from the furnace casing.

6. Remove individual wires from terminals on gas valve.

7. Disconnect Hot Surface Igniter (HSI) wires from HSI.

8. Disconnect Flame Sensor wire from Flame Sensor.

9. Support the manifold and remove the 4 screws that

secure the manifold assembly to the burner assembly

and set aside. Note the location of the green/yellow wire

and ground terminal.

10. Inspect the orifices in the manifold assembly for

blockages or obstructions. Remove orifice and clean or

replace orifice.

11. Remove the four screws that attach the top plate of the

casing to the furnace.

12. Raise top plate up slightly and prop it up with a small

piece of wood or folded cardboard.

13. Support the burner assembly and remove the screws

that attach the burner assembly to the heat exchanger

cell panel.

14. Remove wires from both rollout switches.

15. Slide one

−

piece burner out of slots on sides of burner

assembly.

16. Remove the flame sensor from the burner assembly.

17. (Optional) Remove the Hot Surface Igniter (HSI) and

bracket from the burner assembly.

18. Check igniter resistance. Nominal resistance is 40 to 70

ohms at room temperature and is stable over the life of

the igniter.

19. Clean burner with a brush and a vacuum.

20. Clean the flame sensor with fine steel wool (0000 grade).

Do not use sand paper or emery cloth.

Figure 9

Burner Assembly

B

URNER

A

SSY

F

LAME

S

ENSOR

(

B

ELOW

B

URNER)

F

LAME

R

OLL

−

OUT

S

WITCH

B

URNER

S

UPT.

A

SSY

L11F064

Representative drawing only, some models may vary in appearance.

To reinstall burner assembly:

1. Install the Hot Surface Igniter (HSI) and bracket in burner

assembly.

2. Install flame sensor on burner.

3. Align the edges of the one-piece burner with the slots in

the burner assembly and slide the burners forward until

they are fully seated in the burner assembly.

4. Align the orifices in the manifold assembly with the

support rings on the end of the burner.