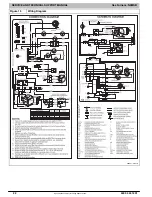

SERVICE AND TECHNICAL SUPPORT MANUAL

Gas Furnace: N9MSB

Specifications subject to change without notice.

26

440 04 4412 01

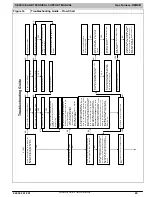

PARTS REPLACEMENT INFORMATION GUIDE

Casing Group

Control door

Blower door

Top filler plate

Bottom filler plate

Door knob assembly

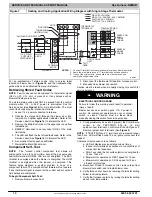

Electrical Group

Control box

Junction box

Limit switch(es)

Circuit board

Door switch

Transformer

3

−

Amp fuse

Flame rollout switch

Main wiring harness

Blower motor harness (when used)

Filter Group

Filter(s)

Blower Group

Cut

−

off plate

Blower housing

Blower motor

Blower wheel

Capacitor (when used)

Capacitor strap (when used)

Power choke (where used)

Gas Control Group

Manifold

Burner

Orifice

Flame sensor

Hot surface igniter

Gas valve

Heat Exchanger Group

Primary Heat Exchanger assembly

Primary Heat Exchanger cell panel

Secondary Heat Exchanger assembly

Coupling box

Containment plate

Tubing gaskets

Inducer Group

Pressure switch(es)

Inducer assembly

Inducer

Inducer motor

Motor module (when used)

Inducer motor capacitor (when used)

Collector box

Condensate trap

Condensate trap elbow

Gaskets

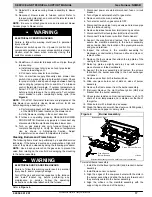

!

WARNING

FIRE, EXPLOSION, ELECTRICAL SHOCK AND CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in dangerous operation, personal injury, death or property damage.

Improper installation, adjustment, alteration, service, maintenance, or use can cause carbon monoxide poisoning, explosion, fire,

electrical shock, or other conditions which may cause personal injury or property damage. Consult a qualified installer, service

agency, local gas supplier, or your distributor or branch for information or assistance. The qualified installer or agency must use only

factory-authorized and listed kits or accessories when modifying this product.

Have available the product/model number and the serial number located on the unit rating plate to ensure correct replacement parts.

TO OBTAIN INFORMATION ON PARTS: Consult your installing dealer or the classified section of your local telephone directory

under the “Heating Equipment“ or “Air Conditioning Contractors and Systems” headings for dealer listing by brand name.