Mode of Operation

The

ICM441

is designed to individually monitor 3 PTC temperature sensors which are wound into

each phase winding of a motor. If any winding or incoming line power is beyond the safe operating

range of the motor, the

ICM441

will lock the motor out of operation until the inputs fall back into

the safe operating range. The

ICM441

can sense shorted or open sensors, in addition to providing

isolation to each sensor to prevent damage to the monitor in the event a sensor shorts to a winding or

case ground.

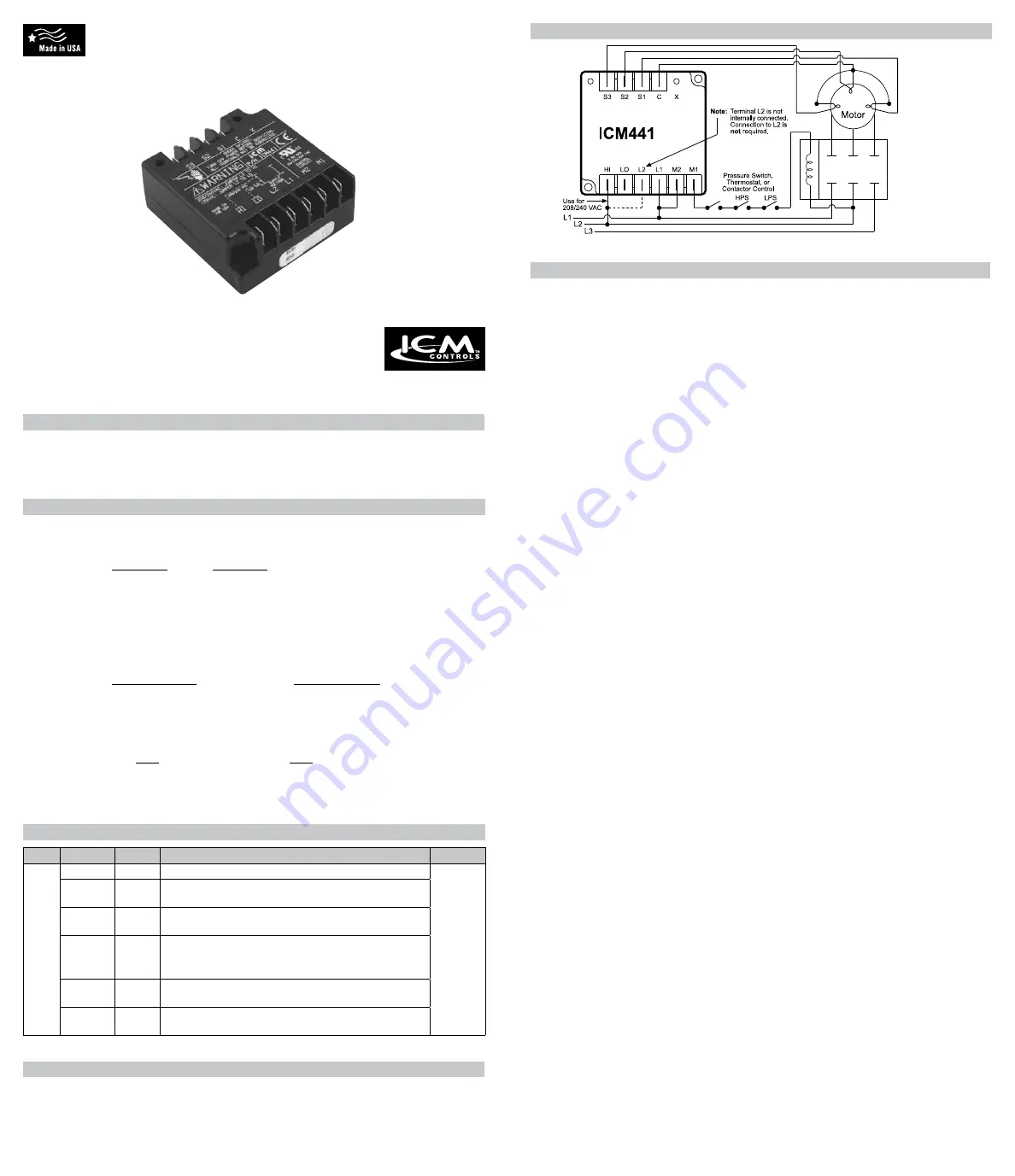

ICM441 System Wiring Diagram

Installation

This installation is only to be performed by a qualified electrician in accordance with NEC standards.

Ensure all power to both motor and control circuits is removed before starting installation. Verify there

is no voltage present with a voltmeter.

This control is typically installed on a three phase motor, where the power for this control comes

directly off one set of phases to the motor (see System Wiring Diagram). If you have an installation

where a step-down transformer drops the voltage supply for this control, please see the section titled

“Step-Down Transformer Installations.”

In applications where this control replaces an existing motor protector of the same voltage and

sensor ratings, label each wire connected to the defective unit before you remove it from that control.

Terminal designations should correspond to terminals on the

ICM441

.

Step 1: Verify sensor integrity

There should be four (4) small gage wires coming from the motor housing, which connect to

internally-wound sensors. There are three sensor wires, and one sensor common wire. At normal

temperature, a motor which has been de-energized for at least one hour will have sensors with a

normal operating resistance of approximately 1K

Ω

. A sensor must be in the range of 500

Ω

to 3K

Ω

when measured with a resistance meter between the sensor common wire and each sensor wire

(S1, S2, and S3). If a sensor is found outside of this range, you must deactivate that sensor from all

sensing, as described in the section labeled “Bypassing A Sensor.”

Step 2: Connect all sensor wires

There should be four (4) small gage wires coming from the motor housing, which connect to

internally-wound sensors. There are three sensor wires, and one sensor common wire. The sensor

common wire connects with female 1/4” quick-connects to the

ICM441

terminal “C” (common). All of

the individual sensor wires connect to the

ICM441

terminals “S1, S2, and S3” with female 1/4” quick-

connects.

Connect sensor wire S1 to terminal “S1,” connect sensor wire S2 to terminal “S2,” and connect

sensor wire S3 to terminal “S3.” The order of these sensors is not important, simply ensure that

each sensor wire is connected to a sensor input on the

ICM441

. Consult the System Wiring Diagram

should any other questions arise.

Step 3: Connect the control circuit

There is always a contactor that supplies operating current to the motor this device protects. This

contactor has an internally wound coil with a specific operating voltage rating. Ensure the operating

voltage rating of this coil is in the range of 24 VAC to 277 VAC, since the

ICM441

has a maximum

rating of 277 VAC on its internal control contacts.

Usually, one side of the contactor coil is connected to power common. Whether a transformer is used

to step-down the control voltage (see the section titled “Step-Down Transformer Installations”) or if it

is powered by line voltage, one side of the coil is typically connected directly to this common. Leave

this connection to the contactor coil as is.

The other side of the contactor coil typically is energized by “hot” through a series of switches, usually

by some type of thermostat, pressure switch, or safety switch. Remove this “switched side” coil wire

from the contactor coil and connect to the

ICM441

terminal “M2” using a 1/4” female quick-connect.

Fashion another wire with female 1/4” quick-connects on both ends to connect between the

ICM441

terminal “M1” and the “switched side” of the coil you just removed the wire from. Consult the System

Wiring Diagram should any other questions arise.

Step 4: Supply operating voltage to the ICM441

The operating voltage required for this unit is 120/240 VAC, 50/60 Hz. Determine what voltage range

will be supplied to the

ICM441

and connect voltage as follows:

• 85-135 VAC: Connect Neutral (or “common” on step-down transformer applications) to the terminal

labeled “L1” on the

ICM441

, via a 1/4” female quick-connect. Connect L1 (or “hot” on step-down

transformer applications) to the terminal labeled “LO” on the

ICM441

, via a 1/4” female quick-

connect. You may connect an additional wire between terminals “LO” and “L2” on the

ICM441

, but

this option is not required. Terminal “L2” has no internal connection, it is provided for backward

compatibility to other models of motor protector.

• 185-277 VAC: Connect L1 (or “common” on step-down transformer applications) to the terminal

labeled “L1” on the

ICM441

, via a 1/4” female quick-connect. Connect L2 (or “hot” on step-down

transformer applications) to the terminal labeled “HI” on the

ICM441

, via a 1/4” female quick-

connect. You may connect an additional wire between terminals “HI” and “L2” on the

ICM441

, but

this option is not required. Terminal “L2” has no internal connection, it is provided for backward

compatibility to other models of motor protector.

Consult the System Wiring Diagram should any other questions arise. Your

ICM441

is now ready for

application of power to the motor and control circuits.

Specification

ENVIRONMENTAL

Epoxy Encapsulated:

For use in extreme environmental conditions

Connection Terminals:

0.25” male spade terminals

Temperature Range:

-40ºC to 85ºC

(storage)

-40ºC to 70ºC

(operating)

Maximum Operating/Storage Relative Humidity:

95% non-condensing

Sensor Shorted, Open, Over Temperature Detection:

0.1 second maximum

Power Loss Detection:

0.1 second maximum

Nominal anti-short cycle Time:

4 minutes (+/- 60 seconds)

Case Dimensions:

3”L x 3.25”W x 1.5”H

ELECTRICAL

User Selectable Operating Voltage:

90-140 VAC RMS and 185-270 VAC RMS (based on field wiring)

Low Voltage Cutout:

85 (+/-5.5) VAC RMS (using 120 VAC input) 170 (+/-10) VAC RMS (using 208 VAC input)

Over Temperature Trip:

Any one sensor input in excess of 11K

Ω

(+/- 1K

Ω

)

Over Temperature Reset:

All three sensor inputs must be less than 3K

Ω

(+/- 500

Ω

)

Shorted Sensor Trip:

Any one sensor input less than 250

Ω

(+/- 50

Ω

)

Shorted Sensor Reset:

All three sensor inputs must be greater than 500

Ω

(+/- 100

Ω

)

N.O. Relay Contact Rating (M1, M2):

2.5 amps resistive @ 277 VAC RMS 2.5 amps inductive @ 277 VAC RMS

Low Power Consumption:

23mA

(nominal) @ 120 VAC @ 25ºC

21mA

(nominal) @ 240 VAC @ 25ºC

Terminal “L2” is Not Internally Connected:

Provided for backward compatibility to competitor models. Not

required for new installations

Temperature Sensors:

Monitors industry standard (3BA and 10BA sensors)

ICM441 Cross Reference Guide

ICM #

T.I. #

Mars #

Copeland #

Bristol #

441

31AA1606 E

241680

15AA1603 B

37304

Replaces:

071-9800-01

Used On:

Copeland: GR, SE

15AA1603 C

37306

Replaces:

071-9800-00

Used On:

Copeland: GR, SE

31AA1600 E

37322

Replaces:

071-0376-01

071-0397-00

071-0424-00

071-0376-02

071-0397-01

071-0424-01

Used On:

Copeland: 4R, 6R, BR, M, 2D, 3D, 4, 6, 8, both Reed & Discus

models

15AA1600 B

37300

Replaces:

071-0376-02

071-0397-01

071-0424-01

Used On:

Copeland: 4R, 6R, BR

15AA1600 C

37302

Replaces:

071-0376-01

071-0397-00

Used On:

Copeland: 4R, 6R, BR

Installation of the ICM441 shall be performed by trained technicians only. Adhere to all local

and national electric codes.

Disconnect all power to the system before making any connections.

Caution

ICM441

Motor Protector

Installation, Operation & Application Guide

For more information on our complete range of American-made products – plus

wiring diagrams, troubleshooting tips and more, visit us at

www.icmcontrols.com