ADJUSTMENT INTERVENTIONS

ADJUSTING THE SQUEEGEE BODY'S RUBBER BLADES

The careful adjustment of the squeegee body rubber blades guarantees better cleaning of the floor.

To adjust the height of the squeegee body:

1.

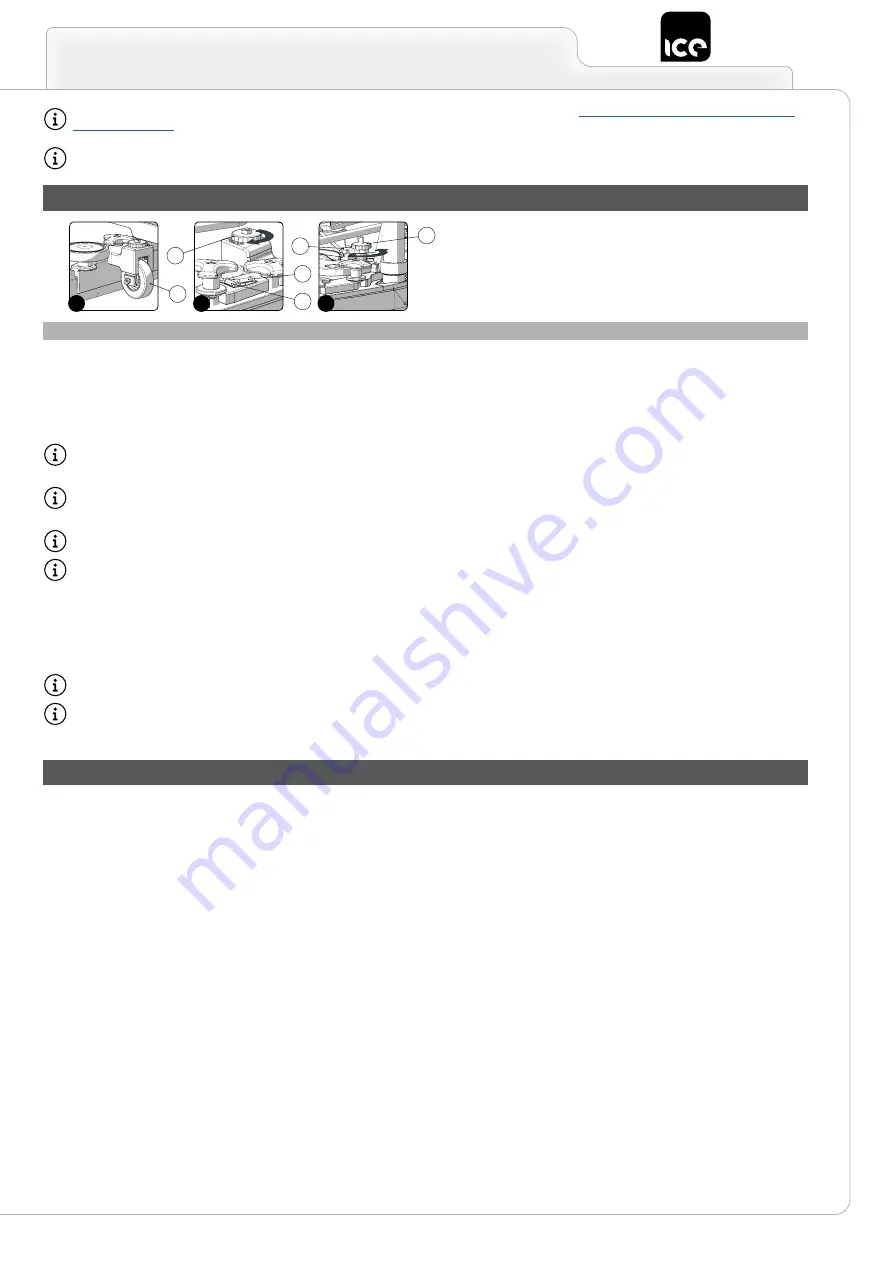

The distance of the squeegee rubber blades from the floor can be adjusted by changing the distance between the wheels (1) located on the

squeegee support and the floor itself (

Fig.1

).

2.

To adjust the height of the wheels, simply use the adjustment knobs (2) located on the squeegee support (

Fig.2

).

N.B.:

To decrease the distance between the wheels and the floor, simply turn the adjustment levers (2) in the direction indicated by the

arrows with the sign "-", while to increase the distance just follow the arrows with the "+" sign.

N.B.:

By decreasing the distance between the squeegee support and the floor, the rubber blades present in the squeegee's body move

closer to the floor.

N.B.:

For effective drying, the wheels must be at the same distance from the floor.

N.B.:

Check for proper adjustment by looking at the instrument (3) positioned on the squeegee body (

Fig.2

).

Adjusting the tilt of the squeegee body:

3.

The angle of incline of the squeegee body is adjusted by rotating the lever (4) located on the squeegee support (

Fig.3

).

4.

To adjust the inclination of the squeegee body, loosen the knob (5) and tighten or loosen the lever (4) (

Fig.3

), until the squeegee body

rubber blades are bent towards the outside evenly along the entire length by about 30° with respect to the floor.

N.B.:

Check for proper adjustment by looking at the instrument (6) positioned on the squeegee body (

Fig.2

).

N.B.:

Moving the lever (4) clockwise will raise the central part of the squeegee body from the floor.

5.

Once the adjustment has been completed, tighten the knob (5).

N.B.:

Before using the machine, remember to adjust the squeegee body: see the section titled “

N.B.:

It is recommended to replace both squeegee body blades in order to ensure good results when drying the floor.

CHOOSING AND USING BRUSHES

POLYPROPYLENE BRUSH (PPL)

Used on all types of floors. Good resistance to wear and tear, and hot water (no greater than 50°C.). PPL is non-hygroscopic and therefore

retains its characteristics even when working in wet conditions.

ABRASIVE BRUSH

The bristles of this type of brush are charged with highly aggressive abrasives. It is used to clean very dirty floors. To avoid floor damage, work

only with the pressure strictly necessary.

BRISTLE THICKNESS

Thicker bristles are more rigid and are therefore used on smooth floors or floors with small joints.

On uneven floors or those with deep joints, it is advisable to use softer bristles which can enter the gaps more easily.

Remember that when the bristles are worn and therefore too short, they will become rigid and are no longer able to penetrate and clean deep

down. In this case, like with over-large bristles, the brush tends to jump.

PAD HOLDER

The pad holder is recommended for cleaning shiny surfaces.

There are two types of pad holder:

1.

The traditional pad holder is fitted with a series of anchor points that allow the abrasive floor pad to be held and dragged while working.

2. the CENTRE LOCK type pad holder not only has anchor points, but also a snap-type central locking system in plastic that allows the abrasive

floor pad to be perfectly centred and held without any risk of it becoming detached. This type of pad holder is recommended above all for

machines with more than one brush, where the centring of the abrasive discs is difficult.

25

1

1

2

3

2

6

3

4

5