UCG GOURMET SERIES UNDERCOUNTER

pg. 14

the size of the cubes. A lower setting will produce a larger cube (oversize) while a higher setting a

smaller cuber (shallow size). When closed on contacts 3‐2 it activates the defrost or harvest cycle

components. The cube size control is set up in the factory (knob in the black dot position) and doesn't

require any adjustment when the ambient temperature remains between 20 and 30

C (70 and 90

F).

UCG 135 – 165

The evaporator thermostat with its sensing bulb intimately in contact with the regrigerant outlet tube

from the evaporator senses the evaporating refrigerant temperature (which declines in the course of

the freezing cycle) and when this one reaches the pre‐set value, it switches its contacts from 3‐4 to 3‐2

to activate the finishing cycle (2nd phase) which has a pre‐set extension determined by the large

diameter lobe of the timer.

FAN MOTOR (Air cooled version)

The fan motor on UCG45/65/85/105 is electrically connected in parallel to the water pump and it

operates continuously only during the freezing cycle keeping the proper head press circulating air

through the condenser fins. On UCG135/165 the operation of fan motor is controlled by a fan pressure

control adjusted at preset values.

COMPRESSOR

The hermetic compressor is the heart of the refrigerant system and it is used to circulate and retrieve

the refrigerant throughout the entire system. It compresses the low pressure refrigerant vapor causing

its temperature to rise and become high pressure hot vapor (hot gas) which is then released through the

discharge valve.

WATER SPRAY SYSTEM

Through its nozzles it sprays the water in each individual cup to be frozen into ice.

SAFETY HI TEMPERATURE THERMOSTAT

Located in the control box it is a manual reset switch that trips OFF the operation of the machine when

its bulb (located on the liquid line just before the drier) reaches the temperature of 70

C (158

F).

CLEANING SWITCH (UCG45/65/85/105)

Located on the bottom left side of the control box is used to energize the water inlet and the hot gas

valves so to charge the water into the sump tank of the machine.

Содержание UCG 45

Страница 2: ...UCG GOURMET SERIES UNDERCOUNTER pg 2...

Страница 10: ...UCG GOURMET SERIES UNDERCOUNTER pg 10...

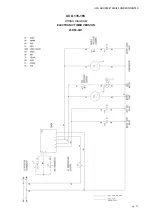

Страница 20: ...UCG 45 65 85 105 WIRING DIAGRAM AIR WATER COOLED 230 50 60 1 pg 20 UCG GOURMET SERIES UNDERCOUNTER...

Страница 21: ...UCG 135 165 WIRING DIAGRAM ELECTRONIC TIMER VERSION 230 50 60 1 pg 21 UCG GOURMET SERIES UNDERCOUNTER...

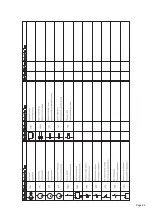

Страница 22: ...Page 22...