177

Adjustment Procedures

8.

The display will show “SERVICE / PRINTER MECHANISM TESTS”, the

first menu item. Press Enter to enter the mechanism tests menu.

9.

Press Scroll

"

or Scroll

#

until

“PRINTER MECHANISM TESTS / END OF FORMS ADJUST” is on the

display.

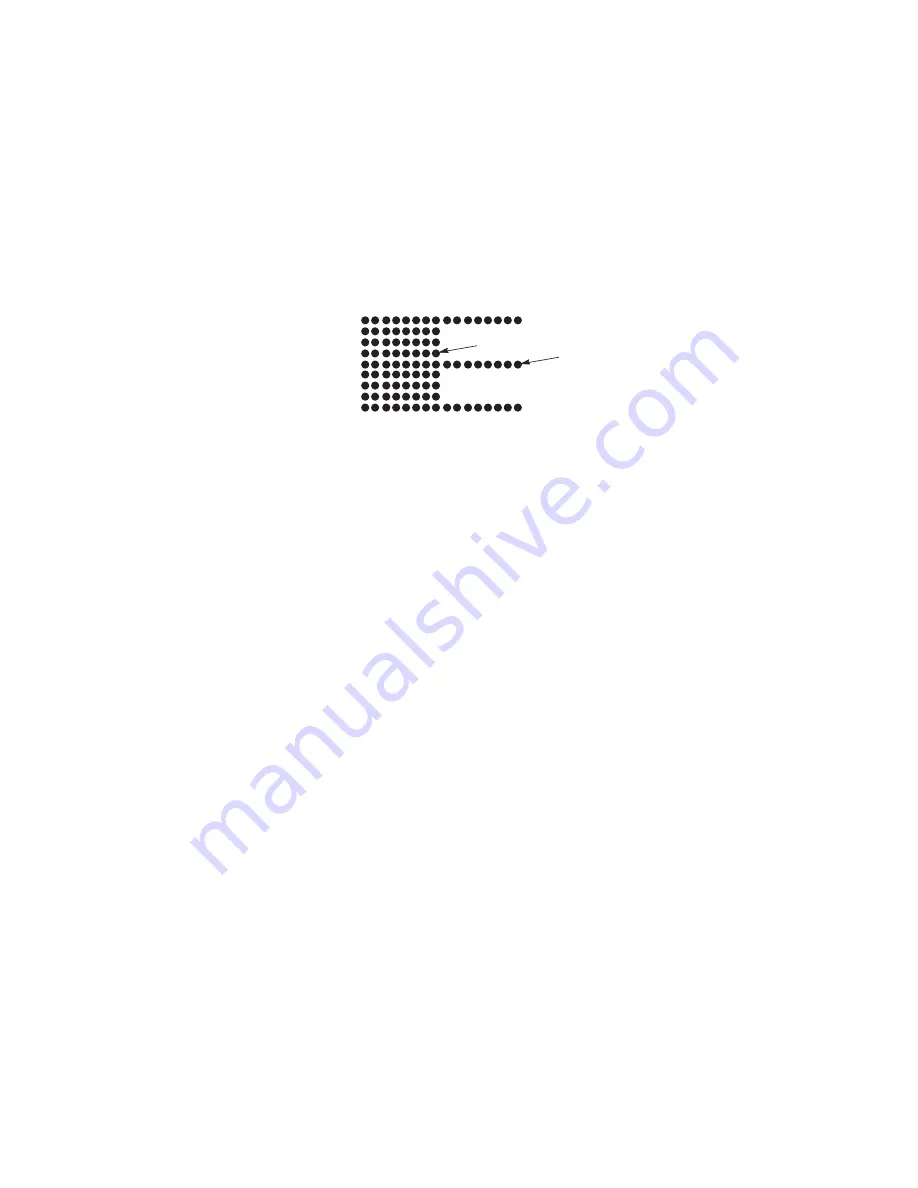

This test will print a vertical “comb” pattern at around column 70, each

long bar separated by three shorter bars. An enlarged example of the

comb pattern is shown below.

Long Bar

Short Bar

10. Press Enter until the END OF FORMS ADJUST test starts.

The comb pattern will print until the display shows

“001 END OF FORMS / LOAD FORMS” and (if enabled) the audible

alarm sounds. If the alarm sounds, press Stop to silence it.

11. Remove the paper from the tractors and examine the area of the page

perforation. (If the alarm sounds when you open the platen, press Stop

to silence it.)

If a bar from the comb pattern just meets the perforation, the end of

forms adjustment distance is correct. (A bar exactly on perforation is

ideal; 1 or 2 dot rows off is OK; 5 to 7 dot rows off is too much.) Unless

you wish to restart the procedure with 6-part paper, you may stop the test

here, and skip to step 22. (See the note at the beginning of this

procedure.)

If the comb pattern stopped short of the perforation or printed beyond the

perforation, go to step 12.

12. Measure how short or long the comb pattern printed by counting the

number of dot rows needed to reach the perforation, or the number of dot

rows that printed beyond the perforation.

NOTE: You can use the long bars to count the dot rows quickly. There are

three dot rows between each long bar, so each long bar increases

the number of dot rows by four. You can also tear off a small piece

of the comb pattern from the beginning of the pattern and use it as a

ruler to help you measure the dot rows required either to reach the

perforation or back up to it.

Содержание 6400 Series

Страница 2: ......

Страница 3: ...S246 0117 06...

Страница 28: ...28 Installation...

Страница 34: ...34 Preventive Maintenance...

Страница 54: ...54 Principles of Operation...

Страница 190: ...190 Adjustment Procedures...

Страница 263: ...263 Replacement Procedures and Illustrated Parts List 7 5 6 8 1 4 3 2 Figure 40 Paper Stacker and Chains...

Страница 265: ...265 Replacement Procedures and Illustrated Parts List 5 1 6 7 8 9 6 6 2 4 3 Figure 41 Control Panel and Cabinet Details...

Страница 269: ...269 Replacement Procedures and Illustrated Parts List 1 7 8 2 3 5 6 4 9 10 3 11 Figure 43 Inside Covers Cabinet Model...

Страница 289: ...289 Replacement Procedures and Illustrated Parts List 1 2 3 6 7 1 8 5 4 Figure 52 IBM Coax Twinax Expansion Board...

Страница 291: ...291 Replacement Procedures and Illustrated Parts List 7 3 4 1 2 6 5 8 9 Figure 53 Ethernet Interface Assemblies...

Страница 292: ...292 Replacement Procedures and Illustrated Parts List...

Страница 305: ...305 Wire Data Cable Routing Cabinet Model...

Страница 307: ...307 Wire Data Cable Routing Pedestal Model...

Страница 309: ...309 Wire Data Cable Assembly AC In Power Supply Description Part No 14H5289 To Power Supply J1 To Circuit Breaker...

Страница 310: ...Wire Data 310 Cable Assembly AC Power Input Description Part No 14H5289 To Circuit Breaker Input Power Connector...

Страница 311: ...311 Wire Data Cable Assembly Card Cage Fan Description Part No 14H5285 PIN 1 PIN 1...

Страница 313: ...313 Wire Data Cable Assembly Exhaust Fan Description Part No 14H5286...

Страница 314: ...Wire Data 314 Cable Assembly Hammer Bank Logic Description Part No 14H5279...

Страница 315: ...315 Wire Data Cable Assembly Hammer Bank Power Description Part No 14H5283 PIN 1 PIN 1...

Страница 317: ...317 Wire Data Cable Assembly MPU Description Part No 14H5329 PIN 1 PIN 3 PIN 2 PIN 1...

Страница 319: ...319 Wire Data Cable Assembly Ribbon Motor Extension Description Part No 63H7464...

Страница 320: ...Wire Data 320 Cable Assembly Shuttle Motor Drive Description Part No 14H5330...

Страница 322: ...Wire Data 322 Cable Assembly Centronics DataProducts Adapter Description Part No 14H5522...

Страница 323: ...323 Wire Data Cable Assembly 5V Remote Power Description Part No 14H5589...

Страница 325: ...325 Wire Data Cable Logic Power Stacker Description Part No 24H8976...

Страница 326: ...Wire Data 326 Cable Power Power Stacker Description Part No 24H8975...

Страница 327: ...327 Wire Data Cable Vertical Rail Power Stacker Description Part No 24H8964...

Страница 328: ...Wire Data 328 Fan Assembly Hammer Bank Description Part No 14H5159 P107 HBF P107 HBF...

Страница 329: ...329 Wire Data Magnetic Pickup Assembly Description Part No 57G1476...

Страница 330: ...Wire Data 330 Switch Assembly Cover Open Description Part No 14H5282...

Страница 331: ...331 Wire Data Switch Assembly Paper Detector Standard Black Back Forms Kit 6400 Description Part No 14H5281 63H5133...

Страница 332: ...Wire Data 332 Switch Assembly Platen Interlock Description Part No 14H5280 P107 PLO...

Страница 344: ...344 Printer Specifications...

Страница 348: ...348 Torque Table...

Страница 356: ...356 Safety Inspection Guide...

Страница 364: ...364 Abbreviations and Signal Mnemonics...

Страница 404: ...404 Power Stacker 75 80 85 90 85 80 Figure 84 Stacker Detail Rollers...

Страница 406: ...406 Power Stacker 95 95 100 Connector Flag Flat Side Key 96 96 Figure 85 Stacker Detail Motor Bracket...

Страница 408: ...408 Power Stacker 95 95 105 Connector Flag Nib Key 97 Figure 86 Stacker Detail Elevator Bracket...

Страница 412: ...412 Power Stacker...

Страница 427: ......

Страница 428: ...Copyright IBM Corp 1995 1998 S246 0117 06 07S246011706 b7 24H8887 0724H8887 b7 163983 001A...