Operation Pattern

Description

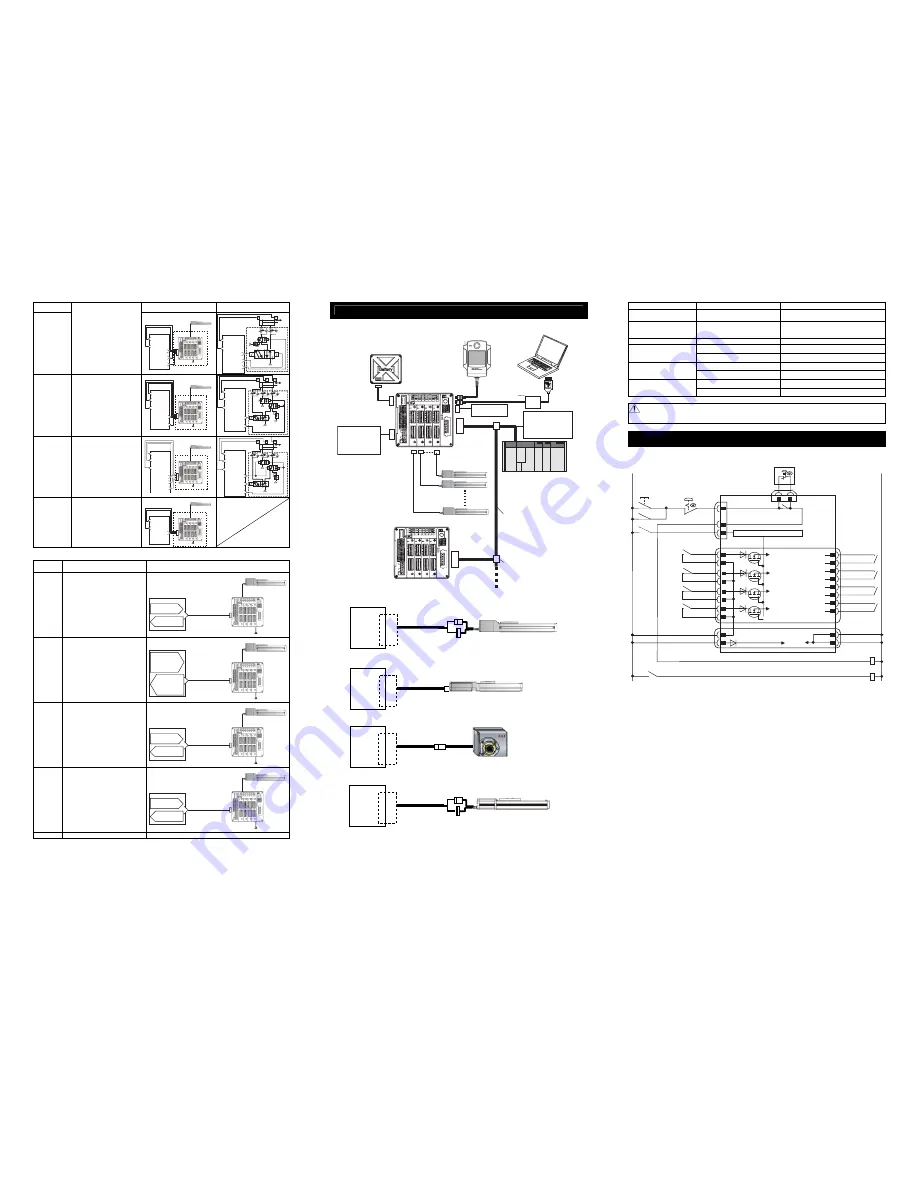

Example for Electric Cylinder Connection

Example for Air Cylinder Connection

(Reference)

PIO Pattern 2

Double Solenoid

System

(Point-to-Point

Movement, Target

Position Setting

(Position Data)

Change)

The pressing operation is available.

+24V

PLC

Backward Position

Movement Signal

(ST0)

Forward Position

Movement Signal

(ST1 )

Target Position

Change Signal

(CN1)

Backward

Position Detection

(LS0)

Forward

Position Detection

(LS1)

Dedicated

Cable

Electric Cylinder

MSEP

R2

R1

B

A

Air Cylinder

PLC

P(Air)

P(Air)

Backward Position

Movement Signal

(ST0)

Forward Position

Movement Signal

(ST1 )

Target Position

Change Signal

(CN1)

Backward

Position Detection

(LS0)

Forward

Position Detection

(LS1)

PIO Pattern 3

(2-Input, 3-Point

Movement)

The actuator 3-Point Movement is

available using the same control

function as for the air cylinder.

The target position setting (forward

position, backward position and

intermediate position) is available.

Speed and acceleration settings in the

actuator movement are available.

Pressing operation is available at the

points except for the intermediate point.

+24V

PLC

Movement

Signal 1

(ST0)

Movement

Signal 2

(ST1 )

Backward

Position Detection

(LS0)

Forward

Position Detection

(LS1)

Intermediate

Position Detection

(LS2)

Dedicated

Cable

Electric Cylinder

MSEP

Air Cylinder

PLC

P(Air)

P(Air)

P(Air)

Movement

Signal 1

(ST0)

Movement

Signal 2

(ST1 )

Backward

Position Detection

(LS0)

Forward

Position Detection

(LS1)

Intermediate

Position Detection

(LS2)

PIO Pattern 4

(3-Input, 3-Point

Movement)

The actuator 3-Point Movement is

available using the same control

function as for the air cylinder.

The target position setting (forward

position, backward position and

intermediate position) is available.

Speed and acceleration settings in the

actuator movement are available.

Pressing operation is available at the

points except for the intermediate point.

+24V

Dedicated

Cable

PLC

Electric Cylinder

Intermediate Position

Movement Signal

(ST2)

Backward Position

Movement Signal

(ST0)

Forward Position

Movement Signal

(ST1)

Backward

Position Detection

(LS0)

Forward

Position Detection

(LS1)

Intermediate

Position Detection

(LS2)

MSEP

Air Cylinder

PLC

P(Air)

P(Air)

P(Air)

Intermediate Position

Movement Signal

(ST2)

Backward Position

Movement Signal

(ST0)

Forward Position

Movement Signal

(ST1)

Backward

Position Detection

(LS0)

Forward

Position Detection

(LS1)

Intermediate

Position Detection

(LS2)

PIO Pattern 5

(Continuous

Reciprocating

Operation)

The actuator’s point-to- point

reciprocating operation is performed

between the forward position and

backward position.

The target position setting (forward

position and backward position) is

available.

Speed and acceleration settings in the

actuator movement are available.

The pressing operation is available.

+24V

PLC

Continuous

Reciprocating

Operation Signal

(ASTR)

Backward

Position Detection

(LS0)

Forward

Position Detection

(LS1)

Dedicated

Cable

Electric Cylinder

MSEP

●

Operation Patterns for Fieldbus Type

Operation

Pattern

Description Overview

Positioner 1/

Simple

Direct Mode

In Positioner 1 Mode, 256 points of

position data can be registered at the

maximum and is able to stop at the

registered positions. Monitoring of the

current position is also available.

In Simple Direct Mode, the target

position can be indicated directly by

inputting a value. Monitoring of the

current position is also available.

Communication with Fieldbus

Dedicated Cable

+24V

Target Position

Target Position No.

Control Signal

PLC

Current Position

Completed Position No.

Status Signal

Electric Cylinder

Direct

Numeric

Specification

Mode

The target position, speed

acceleration/deceleration and pressing

current limit can be indicated with

inputting a number. Monitoring of not

only the current position, but also the

current speed and indicated current are

available.

Communication with Fieldbus

+24V

Target Position

Positioning Width

Speed

Acceleration/Deceleration

Push %

Control Signal

PLC

Current Position

Current Value

(Command Value)

Current Speed

(Command Value)

Alarm Code

Status Signal

Dedicated Cable

Electric Cylinder

Positioner 2

Mode

This is the operation mode of the

position data of 256 points at maximum

set in the position table. The monitoring

of the current position is not available.

This mode is that the transferred data is

reduced from Positioner 1 Mode.

Communication with Fieldbus

+24V

Target Position No.

Control Signal

PLC

Completed Position No.

Status Signal

Dedicated Cable

Electric Cylinder

Positioner 3

Mode

This is the operation mode of the

position data of 256 points at maximum

set in the position table. The monitoring

of the current position is not available.

This is the mode to control with the

minimized number of signals to perform

the positioning operation by reducing

the amount of sent and received data

from Positioner 2 Mode.

Communication with Fieldbus

+24V

Target Position No.

Control Signal

PLC

Completed Position No.

Status Signal

Dedicated Cable

Electric Cylinder

SEP I/O

The same control as PIO is available.

Refer to PIO type

Wiring

1) Connection to RCP2 Series

2) Connection to RCP3, RCP4, RCP5, RCA2 RCD and RCL Series

3) Connection to RCP2 Small Rotary Series

4) Connection to RCA Series

Note 1 Connection Cable Model Codes

□□□

: Cable length Example) 030 = 3m

Model Cable

Remarks

RCP2

(Other than Small Rotary)

CB-PSEP-MPA

□□□

Robot cable from 0.5 to 20m

Small Rotary Type

RCP2-RTBL, RTCL, RTBSL,

RTCSL, RTBBL, RTCBL

CB-RPSEP-MPA

□□□

Robot cable from 0.5 to 20m

RCA CB-ASEP-MPA

□□□

Robot cable from 0.5 to 20m

CB-APSEP-MPA

□□□

Robot cable from 0.5 to 20m

RCP3, RCA2, RCL

CB-APSEP-MPA

□□□

-LC

Standard cable from 0.5 to 20m

CB-CA-MPA

□□□

-RB

Robot cable from 0.5 to 20m

RCP4 (Other than GR* Type),

RCD (Adaptation controller

symbol : D3)

CB-CA-MPA

□□□

Standard cable from 0.5 to 20m

CB-CAN-MPA

□□□

-RB

Robot cable from 0.5 to 20m

RCP4 (GR* Type), RCP5,

RCD (Adaptation controller

symbol : D5)

CB-CAN-MPA

□□□

Standard cable from 0.5 to 20m

Caution: Follow the content described in the model code record card inserted to the controller when connecting

actuators.

Wrong connection will issue an error such as the encoder wire breakage.

Power Supply and Emergency Stop Circuit

The following diagram shows an example of how the emergency stop switch for the teaching pendant may

be included in the emergency stop circuit you may construct.

EMGINSLOT0

EMGINSLOT1

EMGINSLOT2

EMGINSLOT3

Emergency Stop

Reset Switch

Emergency Stop

Switch

CR1

SIO Connector

CR1

24V

0V

Emergency Stop Control Circuit

Motor Power Supply (Slot 3)

(Axis No.6 and 7)

MPISLOT3

MPOSLOT3

CR2

(Note 2)

MPISLOT2

MPOSLOT2

CR2

(Note 2)

MPOSLOT1

MPISLOT1

CR2

(Note 2)

MPISLOT0

MPOSLOT0

CR2

(Note 2)

Motor Power Supply (Slot 2)

(Axis No.4 and 5)

Motor Power Supply (Slot 1)

(Axis No.2 and 3)

Motor Power Supply (Slot 0)

(Axis No.0 and 1)

MP+24V

0V

V

0

V

4

2

+

P

C

Control

Power

External Drive Cutoff •

Emergency Stop Input Connector

Power Line Input Connector

EMG+SLOT0

(Note 6)

S1

4

3

2

1

12

11

10

9

7

8

5

6

15

16

13

14

1

3

4

2

Emergency Stop Switch on

Teaching Pendant

S2

(Note1)

EMG A

EMG B

MSEP

8

5

EMG-

EMG+SLOT1

(Note 6)

EMG+SLOT2

(Note 6)

EMG+SLOT3

(Note 6)

3

2

4

CR1

(Note 4)

CR2

(Note 2)

CR1

System I/O Connector

Note 1 When the teaching pendant is not connected, S1 and S2 become short-circuited inside the controller.

Note 2 When the motor driving source is cut off externally for a compliance with the safety category, connect

a contact such as a contactor to the wires between MPISLOT* and MPOSLOT*.

Note 3 The rating for the emergency stop signal (EMG-) to turn ON/OFF at contact CR1 is 24V DC and

10mA.

Note 4 For CR1, select the one with coil current 0.1A or less.

Note 5 If supplying power with using a 24V DC, having it turned ON/OFF, keep the 0V connected and have

the +24V supplied/cut (cut one side only).

Note 6 By cutting out the connection between EMG+SLOT* and EMGINSLOT*, only the disconnected slot

number can be made in the condition of an emergency stop. (*: Slot Number)

MSEP

AX0 to 7

Actuator

Connector

MSEP

AX0 to 7

Actuator

Connector

MSEP

AX0 to 7

Actuator

Connector

MSEP

AX0 to 7

Actuator

Connector

Connection Cable

(Note 1)

Connection Cable

(Note 1)

Connection Cable

(Note 1)

Connection Cable

(Note 1)

Teaching Pendant

Touch Panel Teaching

(to be purchased separately)

Host System (Master Unit)

(PLC, etc.…Please prepare separately)

Communication power

supply (if necessary)

(24V DC

…Please prepare

separately)

Actuator

Emergency Stop

Circuit

Control/Drive Power

Supply

(24V DC

…Please prepare

separately)

PC software

(to be purchased separately)

Absolute Battery Box

Each Field Network

communication cable

Follow the specifications of

each Field Network for how to

lay out wiring.