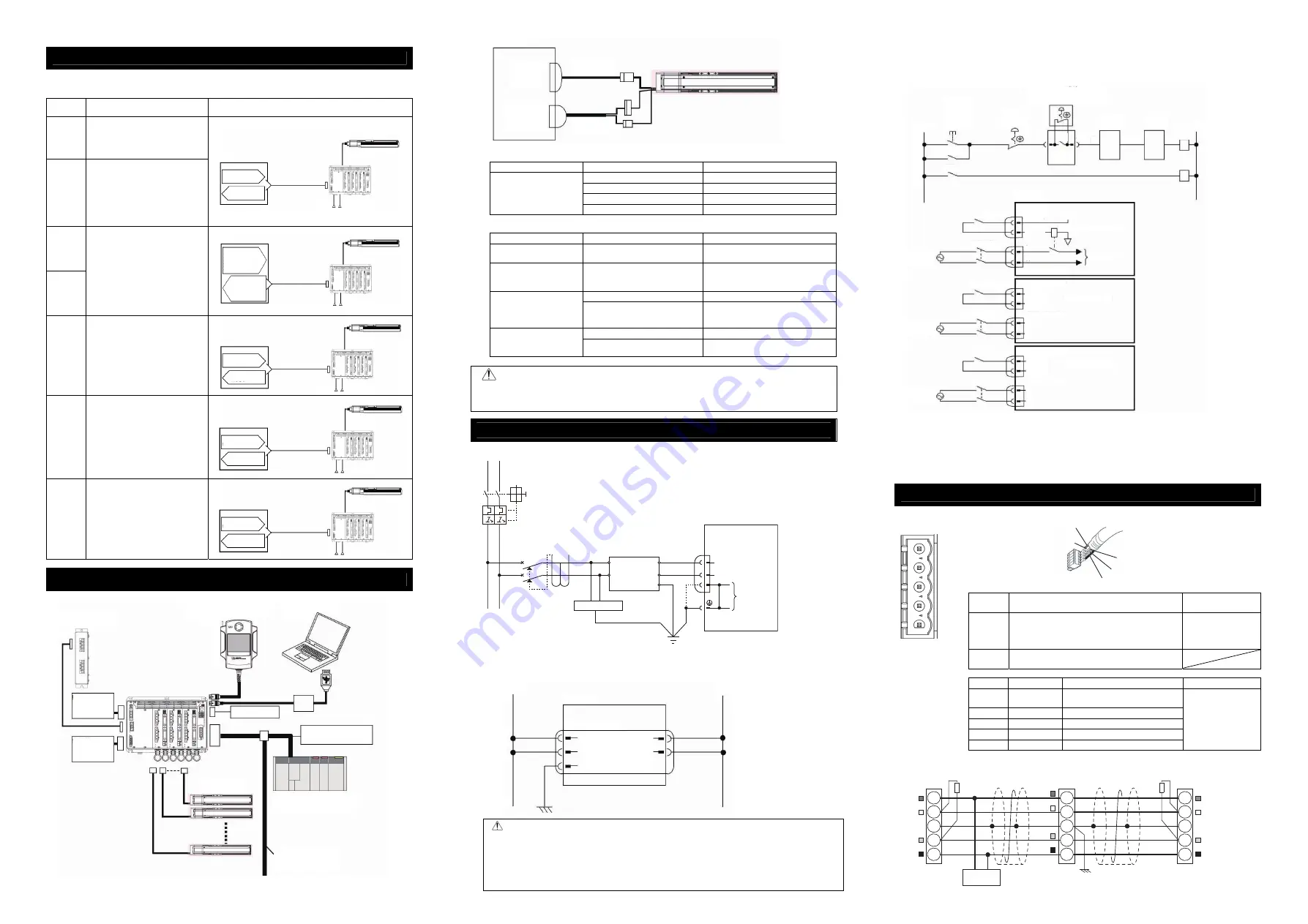

Operation Mode Available

7 types of operation modes are available to select from. The settings are to be established with Gateway

Parameter Setting Tool.

Operation

Pattern

Contents Overview

Positioner

1

In Positioner 1 Mode, 256 points of

position data can be registered at the

maximum and is able to stop at the

registered positions. Monitoring of the

current position is also available.

Simple

Direct

Mode

In Simple Direct Mode, the target

position can be indicated directly by

inputting a value. Monitoring of the

current position is also available.

Those other than the target position

are to be indicated in the position

table, and the setting can be done for

256 points at maximum.

Communication with Fieldbus

Dedicated Cable

100V/200V AC

+24V

Target Position

Target Position No.

Control Signal

PLC

Current Position

Completed Position No.

Status Signal

Electric Cylinder

Direct

Indication

Mode

Direct

Indication

2 Mode

The target position, speed

acceleration/deceleration and

pressing current limit can be indicated

with inputting a number. Monitoring of

not only the current position, but also

the current speed and indicated

current are available.

In Direct Indication 2 Mode,

anti-vibration control is available

instead of JOG operation.

+24V

100V/200V AC

Target Position

Positioning Width

Speed

Acceleration/Deceleration

Push %

Control Signal

PLC

Current Position

Current Value

(Command Value)

Current Speed

(Command Value)

Alarm Code

Status Signal

Communication with Field Network

Dedicated Cable

Electric Cylinder

Position 2

Mode

This is the operation mode of the

position data of 256 points at

maximum set in the position table.

The monitoring of the current position

is not available

This mode is that the transferred data

is reduced from Positioner 1 Mode.

+24V

100V/200V AC

Target Position No.

Control Signal

PLC

Completed Position No.

Status Signal

Communication with Fieldbus

Dedicated Cable

Electric Cylinder

Position 3

Mode

This is the operation mode of the

position data of 256 points at

maximum set in the position table.

The monitoring of the current position

is not available

This is the mode to control with the

minimized number of signals to

perform the positioning operation by

reducing the amount of sent and

received data from Positioner 2 Mode.

+24V

100V/200V AC

Target Position No.

Control Signal

PLC

Completed Position No.

Status Signal

Communication with Fieldbus

Dedicated Cable

Electric Cylinder

Remote

I/O

Five types

(Note 1)

of control same for

PIO are available.

(Note 1) PIO patterns 0, 1, 2, 4 and

5 can be selected (by switching over

in driver board parameters).

+24V

100V/200V AC

Target Position No.

Control Signal

PLC

Completed Position No.

Status Signal

Communication with Fieldbus

Dedicated Cable

Electric Cylinder

Connection Diagram

Note 1 Applicable Moter Cable types

□□□

: cable length Example) 030 = 3m

Model Name

Cable

Reference

CB-RCC-MA

□□□

-RB

Robot cable from 0.5 to 20m

CB-RCC-MA

□□□

Standard cable from 0.5 to 20m

CB-X-MA

□□□

-RB

Robot cable from 0.5 to 20m

For Single Axis Robot

Connection

CB-X-MA

□□□

Standard cable from 0.5 to 20m

Note 2 Applicable Encoder Cable types

□□□

: cable length Example) 030 = 3m

Model Name

Cable

Reference

For Single Axis Robot

Connection

CB-X1-PA

□□□

Robot cable from 0.5 to 20m

For Connection of Single

Axis Robot Equipped with

LS (Option)

CB-X1-PLA

□□□

Robot cable from 0.5 to 20m

CB-X3-PA

□□□

Robot cable from 0.5 to 20m

For RCS2 [models

equipped with LS and

rotary models (RT*) are

excluded]

CB-RCS2-PA

□□□

Standard cable from 0.5 to 20m

CB-X2-PLA

□□□

Robot cable from 0.5 to 20m

RCS2 [for models

equipped with LS and

rotary models (RT*)]

CB-RCS2-PLA

□□□

Standard cable from 0.5 to 20m

CAUTION

The model code and the manufacturing number of the connected actuator are printed on MSCON front

panel. Check the information before connecting the actuator. Wrong connection will issue an error such

as the encoder wire breakage.

Power Line and Emergency Stop Circuit

<Drive (Motor) Power Supply Circuit>

<

Control Power Supply and Brake Power Supply Circuit>

<Emergency Stop Circuit>

It is the example of circuit layout when an emergency switch of the teaching pendant is used to the

emergency stop circuit of the equipment.

Note 1 When the teaching pendant is not connected, S1 and S2 become short-circuited inside the controller.

Note 2 When the motor power must be disconnected externally for safety category compliance, apply a

safety rated contactor between L and N.

Note 3 The rating for the emergency stop signal (EMG-) to turn ON/OFF at contact CR1 is 24V DC and

30mA.

Note 4 For CR1, select the one with coil current 0.1A or less.

DeviceNet Type

Check the instruction manuals for each Field Network master unit and mounted PLC for the details.

Connector

Name

DeviceNet Connector

Cable

Side

SMSTB2.5/5-ST-5.08 AU

Enclosed in standard

package

Manufactured by

PHOENIX CONTACT

Controller

Side

MSTBA2.5/5-G-5.08 ABGY AU

Pin No.

Signal Name

Contents

Applicable Cable

1

V- (BK)

Power Supply Cable Negative

Side

2

CAN L (BL)

Communication Data Low Side

3

Shield (None) Shield

4

CAN H (WT)

Communication Data High Side

5

V+ (RD)

Power Supply Cable Positive Side

DeviceNet

Dedicated Cable

Caution

●

When using an actuator equipped with a brake, supply a brake power (24V DC).

With the power not being supplied, 0A5 Electromagnetic Brake Non-Release Error will occur. Do

not attempt to supply a brake power if there is no actuator with a brake.

●

If having the control power supplied/cut on the 24V DC side, keep the 0V connected and have the

+24V supplied/cut (cut one side only). If cut also on 0V side (cut both sides), it may damage the

internal circuit.

Teaching Pendant

Touch Panel Teaching

(to be purchased separately)

Host System (Master Unit)

(PLC, etc.…Please prepare separately)

Communication power supply

(if necessary) (24V DC…

Please prepare separately)

Actuator

Emergency Stop

Circuit

PC software

(to be purchased separately)

Regenerative Resistor Unit

Follow the specifications of each

Fieldbus for how to lay out wiring.

Control Power

Supply

(24V DC Please

prepare separately)

Drive Power Supply

(100/200V AC

Please prepare

separately)

MSCON

M0 to 5

Motor

Connector

PG0 to 5

Encoder

Connector

Motor Cable

(Note 1)

Encoder Cable

(Note 2)

L, N : AC100V or 200V (to be identified at order)

+24V

MSCON

0V

24V

+

FG

0V

-

Control Power

Supply Connector

Control Power Supply

Brake Power Supply

Shield

BL (CAN L)

RD (V+)

WT (CAN H)

BK (V-)

4

5

1

2

3

Front view of

connector on

controller side

MSCON

DeviceNet Type

V+

Drain

(Shield)

CAN_H

CAN_L

V-

RD

WT

BL

BK

RD

WT

BL

BK

V+

Drain

(Shield)

CAN_H

CAN_L

V+

Drain

(Shield)

CAN_H

CAN_L

V-

RD

WT

BL

BK

Communication power needs to be

supplied by an external device.

Connect the terminal resistor if the unit is

placed at the end of the network.

V-

Terminal Resistance

121

Ω

Terminal Resistance

121

Ω

24V

Power Supply

Class D grounding

(Formerly Class-III grounding : Grounding resistance at 100

Ω

or less)

Master Unit

Slave Device

L

Circuit

Breaker

Leak Current

Noise

Filter

Surge Absorber

MSCON

L

N

PE

(Earth on either

of them)

Class D grounding

(Formerly Class-III grounding:

Grounding resistance at 100

Ω

or less)

Motor Power Supply

Connector

Screw Terminal for

Protective Grounding

N

Emergency Stop

Reset Switch

Emergency

Stop Switch

Emergency stop switch

for the teaching pendant

(Note 1)

MSCON

Second Unit

MSCON

Second Unit

MSCON

nth Unit

+24V

CR1

S1

S2 S1

S2

S1

S2

MC1

EMG+

EMG-

+24V

L

N

CR

1

(Note 1)

CR1

(Note 3)

MC1

(Note 2)

CR1

(Note 3)

MC1

(Note 2)

CR1

(Note 3)

MC1

(Note 2)

CR1

(Note 1)

0V

MSCON

AC100V

AC200V

AC100V

AC200V

AC100V

AC200V

System I/O

Connector

System I/O Connector

Motor Power Cutoff Relay

Motor

Power Supply

Motor Power Input Connector

Motor Power Input Connector

EMG+

EMG-

L

N

MSCON Second Unit

System I/O Connector

Motor Power Input Connector

MSCON nth Unit

EMG+

EMG-

L

N