●

Specifications of CompoNet Interface

Item Specification

Communication System

CompoNet dedicated protocol

Communication Type

Remote I/O communication

Baud Rate

Automatically follows the master

Communication Cable Length

Follows CompoNet specifications

Slave Type

Word-Mixed Slave

Available Node Addresses for Setting

0 to 63 (Setting conducted on controller parameter)

Number of Occupied Channels

Refer to “3.4.1 PLC Address Construction by each Operation Mode” in the

Instruction Manual for ERC3 Gateway Unit.

Communications Cable

(Note 1)

Round Cable (JIS C3306, VCTF2-core)

Flat cable I (with no sheathed)

Flat cable II (sheathed)

Connector (Controller Side)

XW7D-PB4-R (Manufactured by OMRON or equivalent)

Note 1 Prepare the communication cable separately.

●

Specifications of MECHATROLINK-I/II Interface

Item Specification

Slave Type

Intelligent I/O

MECHATROLINK I 4Mbps

Baud Rate

MECHATROLINK II 10Mbps

Max. Transmittable Distance

50m

Min. Distance between Stations

0.5m

Number of occupied Bytes

Refer to “3.4.1 PLC Address Construction by each Operation Mode” in the

Instruction Manual for ERC3 Gateway Unit.

MECHATROLINK I 15 stations

Number of

Connectable Slaves MECHATROLINK II 30 stations (Repeater is required for connections of more than 17 stations)

Transmission Frequency

1 to 8ms

MECHATROLINK I 17 byte

Data Length

MECHATROLINK II 17/32 byte

Settable Node Address Range

61 to 7F [hex.]

Communications Cable

(Note 1)

Twist Pair Cable with a Shield (characteristic impedance 130

Ω

)

Connected Connector on Controller Side DUSB-ARB82-T11A-FA (Manufactured by DDK or equivalent)

Note 1 Prepare the communication cable separately.

●

Specifications of EtherNet/IP Interface

Item Specification

Communication Protocol

IEC61158 (IEEE802.3)

Baud Rate

10BASE-T/100BASE-T (Autonegotiation setting is recommended)

Communication Cable Length

Follows EtherNet/IP specifications (Distance between hub and each node: 100m

max.)

Number of Connection

Master Unit

Available Node Addresses for Setting

0.0.0.0 to 255.255.255.255

Communications Cable

(Note 1)

Category 5e or more

(Double shielded cable braided with aluminum foil recommended)

Connector

RJ45 Connector × 1pc

Note 1 Prepare a LAN cable separately for the communication cable.

●

Specifications of EtherCAT Interface

Item Specification

Communication Protocol

IEC61158 type 12

Physical Layer

100Base-TX (IEEE802.3)

Baud Rate

Automatically follows the master

Communication Cable Length

Follows EtherCAT® specifications (Distance between each node: 100m max.)

Slave Type

I/O slave

Available Node Addresses for Setting

0 to 127 (17 to 80: When connected to the master (CJ1W-NC*82) manufactured by

OMRON)

Communications Cable

(Note 1)

Category 5e or more

(Double shielded cable braided with aluminum foil recommended)

Connector

RJ45 Connector × 2pcs (Input × 1, Output × 1)

Connect

Daisy chain only

Note 1 Prepare a LAN cable separately for the communication cable.

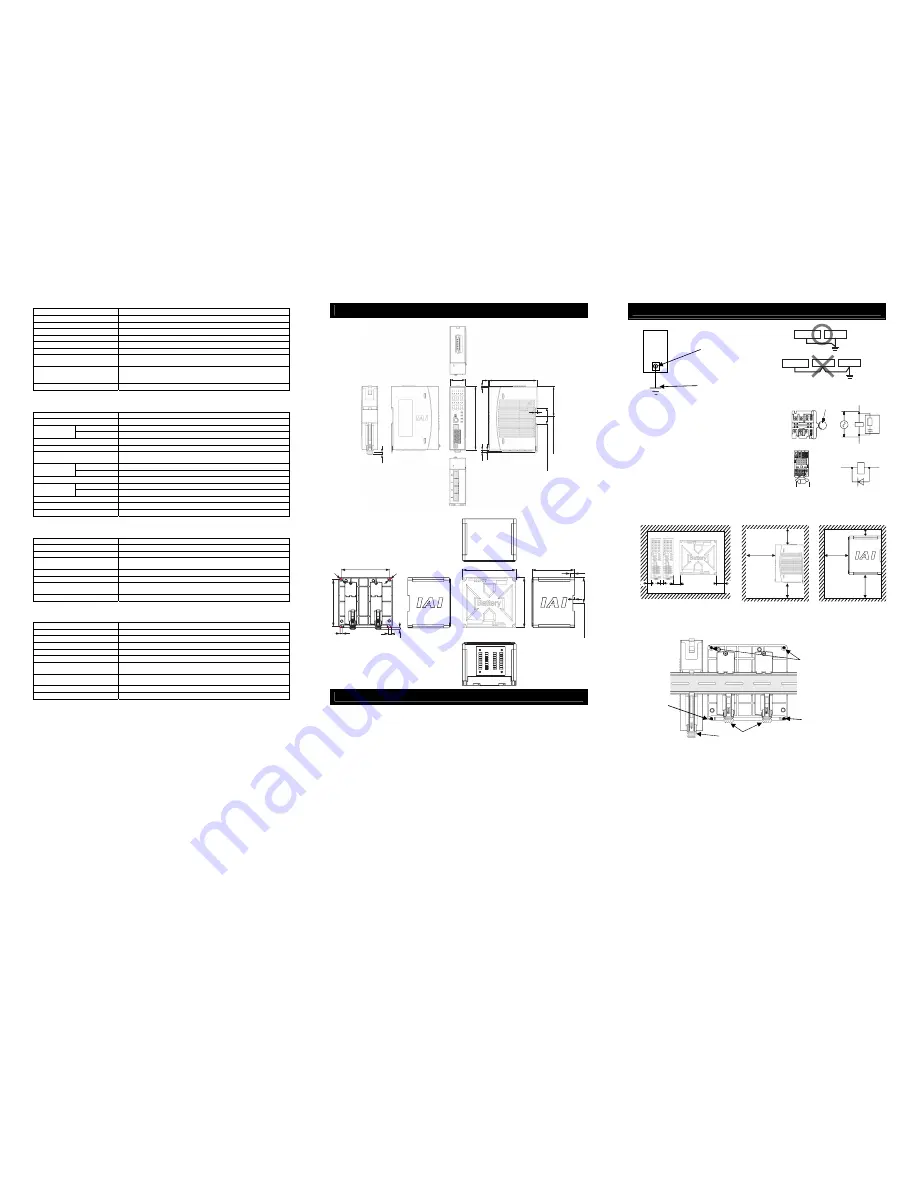

External Dimensions

Gateway Unit Main Body

Absolute Battery Box

Installation Environment

This product is capable for use in the environment of pollution degree 2

*1

or equivalent.

*1 Pollution Degree 2 : Environment that may cause non-conductive pollution or transient conductive

pollution by frost (IEC60664-1).

1. Installation Environment

Do not use this product in the following environment.

•

Location where the surrounding air temperature exceeds the range of 0 to 40

°

C

•

Location where condensation occurs due to abrupt temperature changes

•

Location where relative humidity exceeds 85%RH

•

Location exposed to corrosive gases or combustible gases

•

Location exposed to significant amount of dust, salt or iron powder

•

Location subject to direct vibration or impact

•

Location exposed to direct sunlight

•

Location where the product may come in contact with water, oil or chemical droplets

•

Environment that blocks the air vent [Refer to 1.7 Noise Elimination and Mounting Method]

When using the product in any of the locations specified below, provide a sufficient shield.

•

Location subject to electrostatic noise

•

Location where high electrical or magnetic field is present

•

Location with the mains or power lines passing nearby

2. Storage and Preservation Environment

•

Storage and preservation environment follows the installation environment. Especially in a long-term storage,

consider to avoid condensation of surrounding air.

Unless specially specified, moisture absorbency protection is not included in the package when the machine is

delivered. In the case that the machine is to be stored in an environment where dew condensation is anticipated, take

the condensation preventive measures from outside of the entire package, or directly after opening the package.

Installation and Noise Elimination

1. Noise Elimination Grounding (Frame Ground)

2. Precautions regarding wiring method

1) Wire is to be twisted for the 24V DC power supply.

2) Separate the signal and encoder lines from the power supply and

power lines.

3. Noise Sources and Elimination

Carry out noise elimination measures for electrical devices on the same

power path and in the same equipment.

The following are examples of measures to eliminate noise sources.

1) AC solenoid valves, magnet switches and relays

[Measure] Install a Surge absorber parallel with the coil.

2) DC solenoid valves, magnet switches and relays

[Measure] Mount the windings and diodes in parallel. Select a diode

built-in type for the DC relay.

4. Cooling Factors and Installation

Design and Build the system considering the size of the controller box, location of the Gateway Unit and cooling factors to

keep the ambient temperature around the Gateway Unit below 40

°

C.

Pay a special attention to the battery unit since the performance of it would drop both in the low and high temperatures.

Keep it in an environment in the room temperature as much as possible. (Approximately 20

°

C is the recommended

temperature.)

For the Gateway attachment, affix it on the DIN rail. For the attachment of the battery box, use the 4

attachment holes on each corner of the unit or affix it on the DIN rail.

Rear View

Earth Terminal

Class D grounding (Formerly Class-III grounding :

Grounding resistance at 100

Ω

or less)

Copper wire: Connect a ground

wire with a diameter of 1.6 mm

(2mm

2

: AWG 14) or larger.

Connect the ground line

to the FG terminal block

on the controller unit.

Gateway

Unit

φ

5 fixture hole

φ

5 fixture hole

φ

5 fixture hole

DIN rail

Lever for attachment to DIN rail

(5)

36

140

5.9

1.9

2

(3)

105

4

35.4 (Width of 35mm DIN rail)

65 from DIN rail center

Do not share the ground wire with or connect

to other equipment. Ground each controller.

Controller

Other

equipment

Controller

Other

equipment

Other

equipment

Surge absorber

Relay

coil

Relay coil

R

C

+24V

0V

+24V

0V

+

-

111

10

8

59 from DIN rail center

10.5

φ

5

φ

5

5

5

(4

)

4

123

11

5

98

20mm or more

50mm

or more

50mm

or more

30mm

or more

20mm

or more

30mm

or more

20mm

or more

Ensure

enough

space for

wiring.

Absolute Battery Box

Ensure

enough

space for

wiring.

50mm

or more

50mm

or more

100mm

or more

Gateway Unit