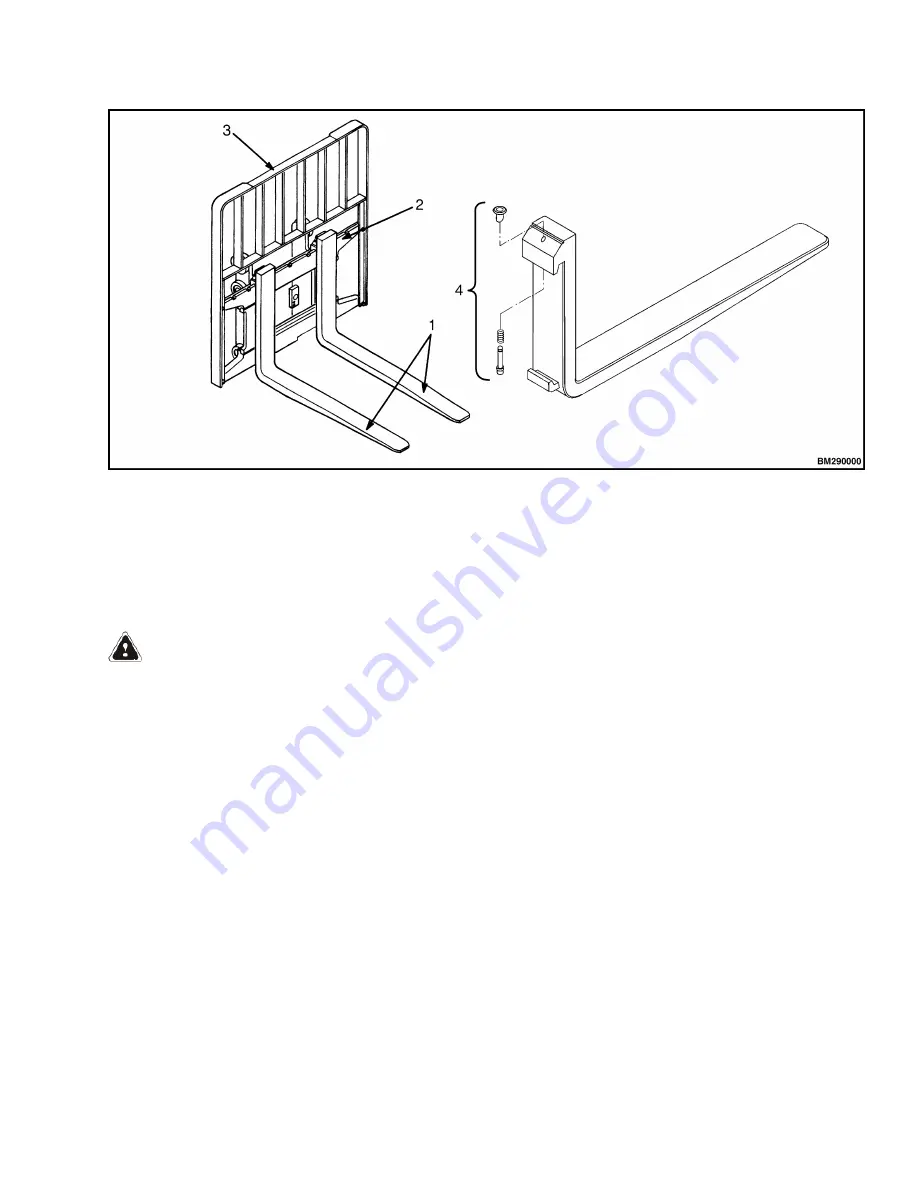

1. FORK

2. CARRIAGE

3. LOAD BACKREST

4. LOCK PIN

Figure 9. Fork Assembly

1.

Inspect the welds on the mast and carriage for

cracks. Make sure the nuts and capscrews are

tight.

WARNING

Always wear the proper protective equipment in-

cluding eye protection and petroleum-resistant

gloves when handling hydraulic oil. Thoroughly

wash oil from exposed areas of skin as soon as

possible.

Never check for leaks by putting hands on hy-

draulic lines or components under pressure. Hy-

draulic oil under pressure can be injected into the

skin.

Completely lower forks to relieve hydraulic pres-

sure before disassembling any part of the lift

pump or disconnecting any hydraulic hoses.

2.

Inspect the mast header hoses and fittings for

hydraulic leaks. Check the hose cover for cracks

or exposed reinforcement. Check for broken or

defective clamping devices. Repair or replace

any damaged components as necessary.

3.

Inspect the channel for excessive wear in the

areas of roller contact. Check the rollers for

wear or damage.

4.

Inspect the load backrest extension for cracks

and damage.

5.

Inspect the forks for cracks and wear. See Fig-

ure 10. Check that the fork tips are aligned

within

3%

of

each

fork

length

[32.00 mm (1.26 in.) for a standard

1067 mm (42 in.) fork]. Some applications can

require closer alignment. Check that the bot-

tom of the fork is not worn. Check that the

thickness of the fork blade (5, Figure 10) is at

least 90% of the thickness of the fork shank

(DIMENSION X). The fork's thickness can also

be checked using fork tool 3020387.

8000 SRM 1379

Maintenance Procedures Every 8 Hours or Daily

15