Repairs

2200 SRM 1357

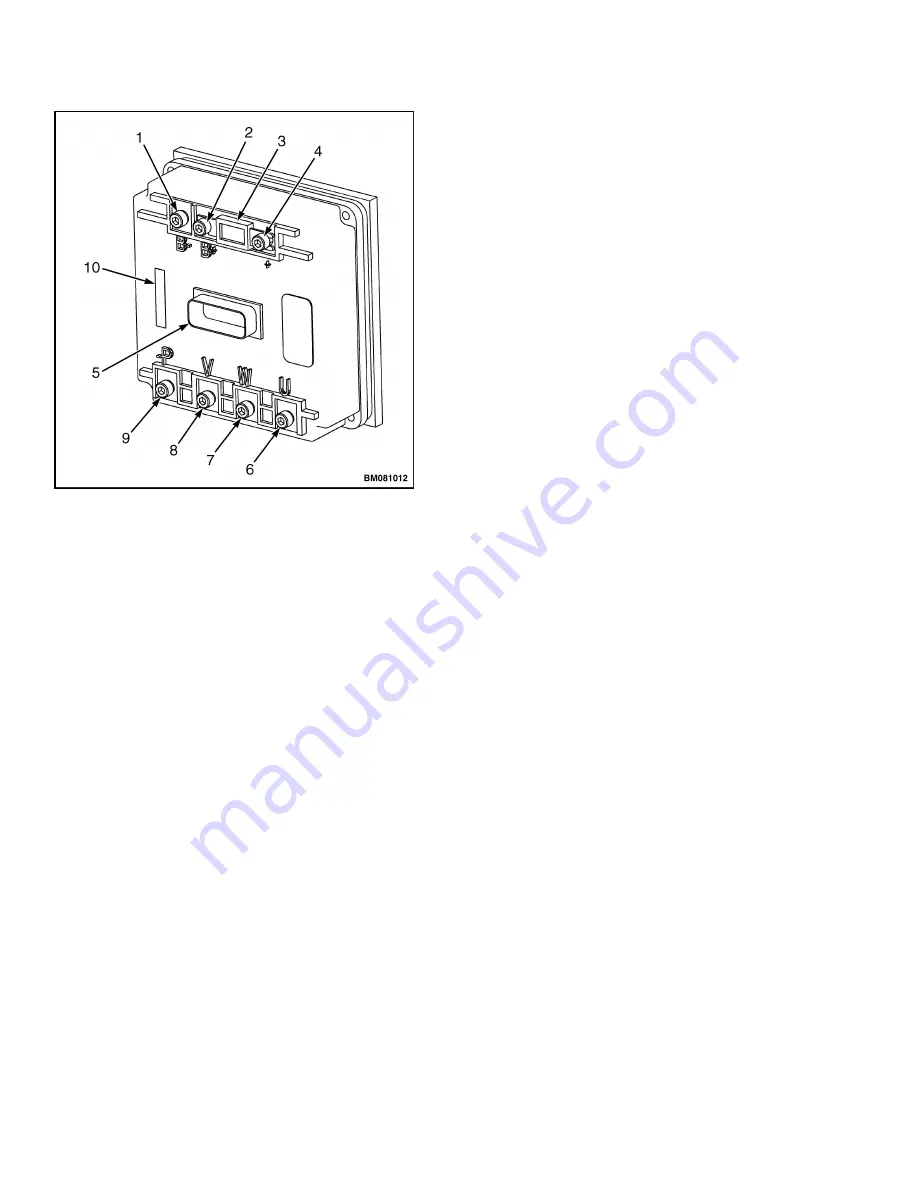

1.

B– TERMINAL

2.

B+ TERMINAL (POS CONNECTION STD)

3.

MAIN FUSE (STD LOCATION)

4.

+ TERMINAL (POS CONNECTION EE)

5.

MAIN CONNECTOR

6.

TRACTION MOTOR POS (TERMINAL U)

7.

TRACTION MOTOR POS (TERMINAL W)

8.

TRACTION MOTOR POS (TERMINAL V)

9.

PUMP MOTOR POS (TERMINAL P)

10. LABEL (PART NUMBER)

Figure 7. Controller Wiring

4.

Discharge the capacitor. See Special Precautions

in this section.

5.

Tag and disconnect wires from the controller. See

Figure 7.

6.

Remove mounting screws and remove controller.

Install

1.

Install replacement controller on lift truck using

mounting hardware.

2.

On models with the Arctic option, install shield

box to controller studs and secure using four

nuts.

3.

Connect wires and cables to the proper terminals

as identified during the removal procedure.

4.

Connect battery and turn the key switch to the

ON position.

5.

Turn parking brake to the OFF position and test

for proper operation.

6.

Install the drive unit compartment covers. See

the section Periodic Maintenance 8000 SRM

1368.

CONTROL MODULE

Check

The control module converts analog signals from the

control handle to digital signals for the controller to

read. If the controller is reporting an input error

fault code, then the control module may be malfunc-

tioning. Check the control module using the follow-

ing steps. See Figure 8.

1.

Connect the battery and turn the key switch to

the ON position. Make sure the parking brake

switch is in the OFF position.

2.

Connect the negative voltmeter lead to the nega-

tive battery cable connection at the controller.

3.

Disconnect the output connector (J5) from the

control module.

4.

Using the positive voltmeter lead, test pin #6 at

the output connector (J5-6).

5.

If there is no voltage at J5-6 then troubleshoot

the controller. See the section AC Motor Con-

troller 2200 SRM 1352.

6.

If the voltmeter shows the proper reading (+24V),

check the input connector (J4) voltages. See Ta-

ble 2.

NOTE:

Voltage should be present at J4-2, J4-3, J4-6,

and J4-9 ONLY while activating the corresponding

function. See Table 2.

7.

If the input values differ from those in the table,

troubleshoot the control handle components, con-

troller, and wiring. Make any necessary repairs,

and recheck the input values.

8.

If the input values are correct, replace the control

module. See Remove.

NOTE:

ETACC may be used to check communication

between control handle, control module, and traction

controller. See the section AC Motor Controller

2200 SRM 1352.

10