15

Operation and maintenance manual for

Hydrotech Drumfilter HDF501-series

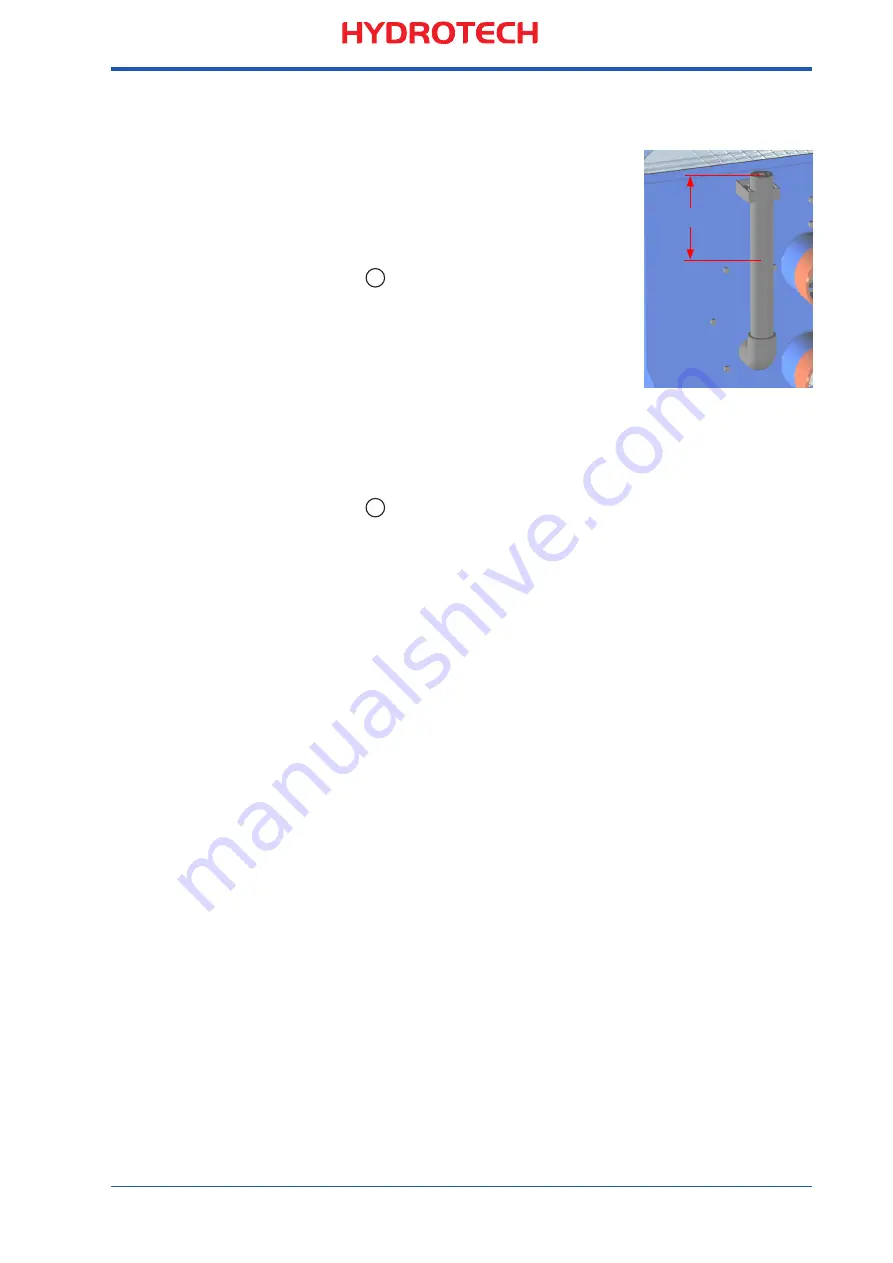

5.2.3.Adjusting.the.level.sensor

Adjust the level sensor to 230-250 mm below the

top of the level pipe. The optimal position depends

on how turbulent the water surface is (see

Figure

5.5.2

).

5.2.4.Setting.the.time.relay

A time relay (see

5

Figure 5.2

) is used to delay

the backwash stop when the water level is below

the level sensor. The time relay is preset so that the

drum is backwashed during one rotation.

In some applications it might be necessary to

increase the backwash time delay to avoid long

term clogging.

5.2.5.Setting.the.level.relay

The sensitivity of the level sensor can be set from MIN. to MAX. on the level

relay and three different sensitivity ranges can be selected on the lower level

relay switch (see

6

in

Figure 5.2

).

If the appropriate sensitivity is not within the selected range change it to

another sensitivity range. For water with a high conductivity (= low resistance)

chose setting 1. For water with a low conductivity (= high resistance) chose

setting 3. Sea water, for example, has a high conductivity.

See also appendix E, level sensors.

5.3.Backwash.system

The standard backwash nozzles (TeeJet 6505) have an equivalent opening

size of 1.4 mm. For some applications it may be necessary to use a lower

rinse water flow. This can be achieved by installing nozzles with a smaller

opening size. Contact the supplier or Hydrotech for more information.

The backwash system pressure is set to 7-8 bars.

5.4.Drum.rotation

The filter is powered by a gear motor that rotates the drum by direct drive.

Direction of rotation is marked on the motor cover.

5.5.Re-tightening.of.bolts

After two working weeks or 80 production hours, all bolted joints must be re-

tightened.

Figure 5.5.2

Adjusting the level sensor

230-250 mm