8

9

VI. PUMP INSTallaTION

1. The pump shall be installed in a well ventilated, free of freezing, free of sun an rain.

2. The pipeline of suction inlet shall be as short as possible. An elbow shall be used in

the corner to reduce the loss of pipeline.

3. It is better that the suction pipe should be larger than the inlet of the pump. Connect

it with the pump after changing the diameter.

4. The suction pipe shall not be higher in the front and lower in the rear to prevent the

air locks.

5. The suction end of the suction inlet shall be fully immerged into the liquid and ensure

the joints to be well scaled to prevent from air in.

6. The mounting height of the pump shall not exceed its allowable suction height.

7. To avoid the distorsion of the pump due to the gravitation from the pipeline, suction

pipeline ans discharge pipeline shall have separate support device.

8. Pressure gauge shall be installed on the outlet of the pump for observation and

controlling the operation of the pump.

9. In case suction liquid level is lower than the suction inlet of the pump. the bottom

valve shall be installed.

10. The motor shall be earthed. Electric devices shall be ensured not to be damaged

by phase shortage, unstable voltage and overload.

WARNING - Electrical connection and safety devices

· The pump units should be connected to the power supply by the appropriately rated

power cables according to the motor ratings.

· The pump units should always be equipped with safety devices as required in

the standars (EN 809 and / or EN 60204-1) as well as by the national rules of the

country where the pump is used.

· Despite the rules of any country, the power supply to the pump unit must be

equipped with at least following electrical safety devices with appropriate ratings:

- Emergency switch

- Circuit breaker (as a supply disconnecting (isolating) device as well as an

overcurrent protective device)

- Motor overload protection

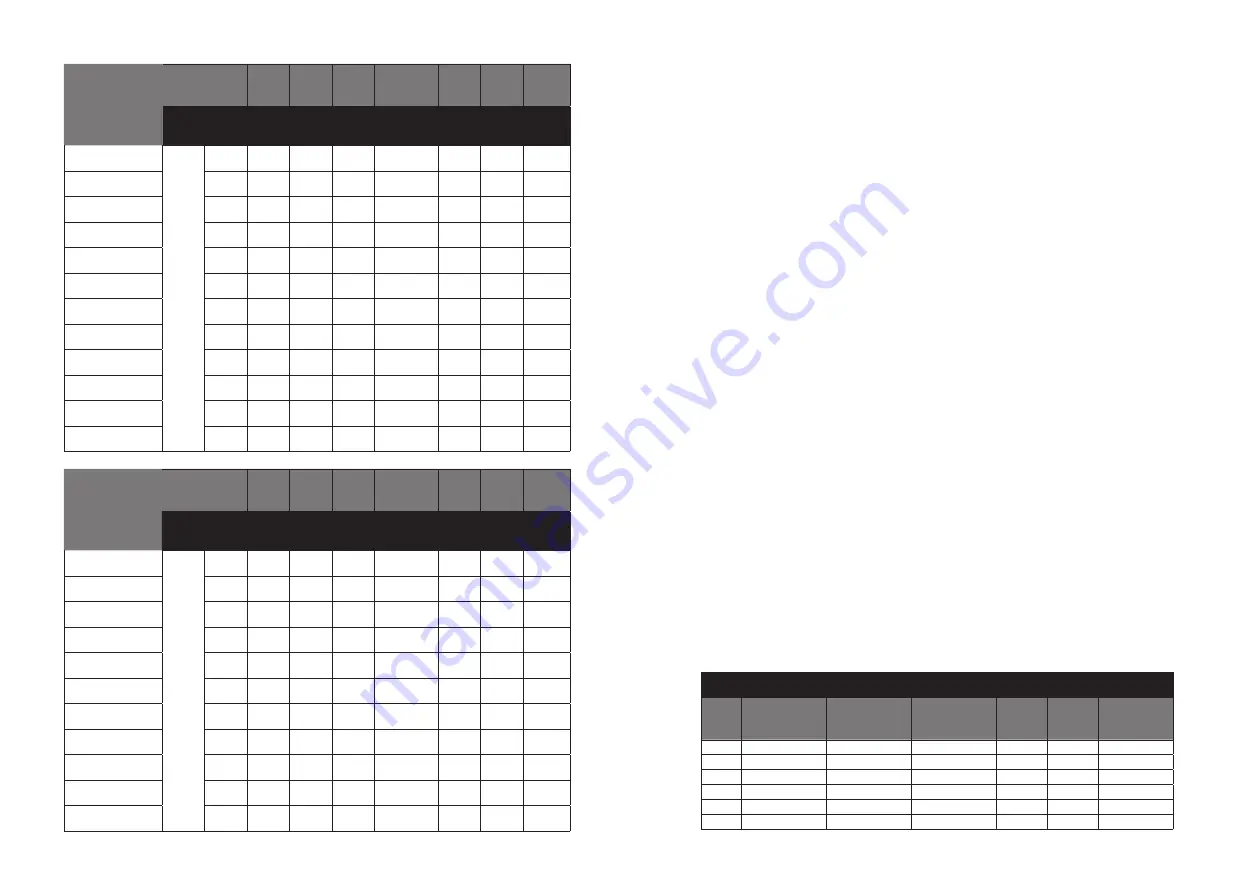

The following table is for suggestion:

Model

Motor

L1

L2

L3

H

(3HP/1HP)

DN S

DN D Weight

Phase Power

(KW)

(mm)

Inlet

Outlet

kg

MX, MN 60/0.37

3PH

1PH

0.37

328

113

51

216/230

G1-1/4

G1

10

MX, MN 60/0.55

0.55

328

113

51

216/230

G1-1/4

G1

12

MX, MN 60/0.75

0.75

361

113

51

223/245

G1-1/4

G1

14

MX, MN 100/0.55

0.55

328

113

51

216/230

G1-1/4

G1

12

MX, MN 100/1.1

1.1

361

113

51

223/245

G1-1/4

G1

16

MX, MN 160/0.75

0.75

375

127

54

223/245

G1-1/2 G1-1/4

14

MX, MN 160/1.1

1.1

375

127

54

223/245

G1-1/2 G1-1/4

16

MX, MN 250/1.1

1.1

375

127

54

223/245

G1-1/2 G1-1/4

16

MX, MN 250/1.5

1.5

415

127

54

232/253

G1-1/2 G1-1/4

20

MX, MN 250/2.2

2.2

415

127

54

232/253

G1-1/2 G1-1/4

23

MX, MN 330/1.5

1.5

415

127

54

232/253

G1-1/2 G1-1/4

20

MX, MN 330/2.2

2.2

415

127

54

232/253

G2

G1-1/4

23

Model

Motor

L1

L2

L3

H

(3HP/1HP)

DN S

DN D Weight

Phase Power

(KW)

(mm)

Inlet

Outlet

kg

MX, MN 100/0.75

3PH

1PH

0.75

361

113

51

223/245

G1-1/4

G1

14

MX, MN 100/1.1

1.1

361

113

51

223/245

G1-1/4

G1

14

MX, MN 100/1.5

1.5

401

113

51

232/253

G1-1/4

G1

20

MX, MN 160/1.1

1.1

375

127

54

223/245

G1-1/2 G1-1/4

16

MX, MN 160/1.5

1.5

415

127

54

232/253

G1-1/2 G1-1/4

20

MX, MN 160/2.2

2.2

415

127

54

232/253

G1-1/2 G1-1/4

23

MX, MN 250/1.1

1.1

375

127

54

223/245

G1-1/2 G1-1/4

16

MX, MN 250/1.5

1.5

415

127

54

232/253

G1-1/2 G1-1/4

20

MX, MN 250/2.2

2.2

415

127

54

232/253

G1-1/2 G1-1/4

23

MX, MN 330/1.5

1.5

415

127

54

232/253

G2

G1-1/4

20

MX, MN 330/2.2

2.2

415

127

54

232/253

G2

G1-1/4

23

380V 50Hz/60Hz

No.

Power input

(kW)

Cable

connection

Input current

(A)

Cable

spec

(mm

2

)

Circuit

breaker

(A)

Thermal

protector

(A)

1

0.37

Y

1.

0.75

5

1.2

2

0.55

Y

1.4

0.75

5

1.7

3

0.75

Y

1.8

0.75

5

2.2

4

1.1

Y

2.6

1

5

3.1

6

1.5

Y

3.5

1

10

4.2

8

2.2

Y

4.9

1.5

10

5.9

Содержание MDROO Series

Страница 8: ...14 15 Notes ...