9

CHANGES AND T YPING ERRORS RESERVED

CHANGES AND T YPING ERRORS RESERVED

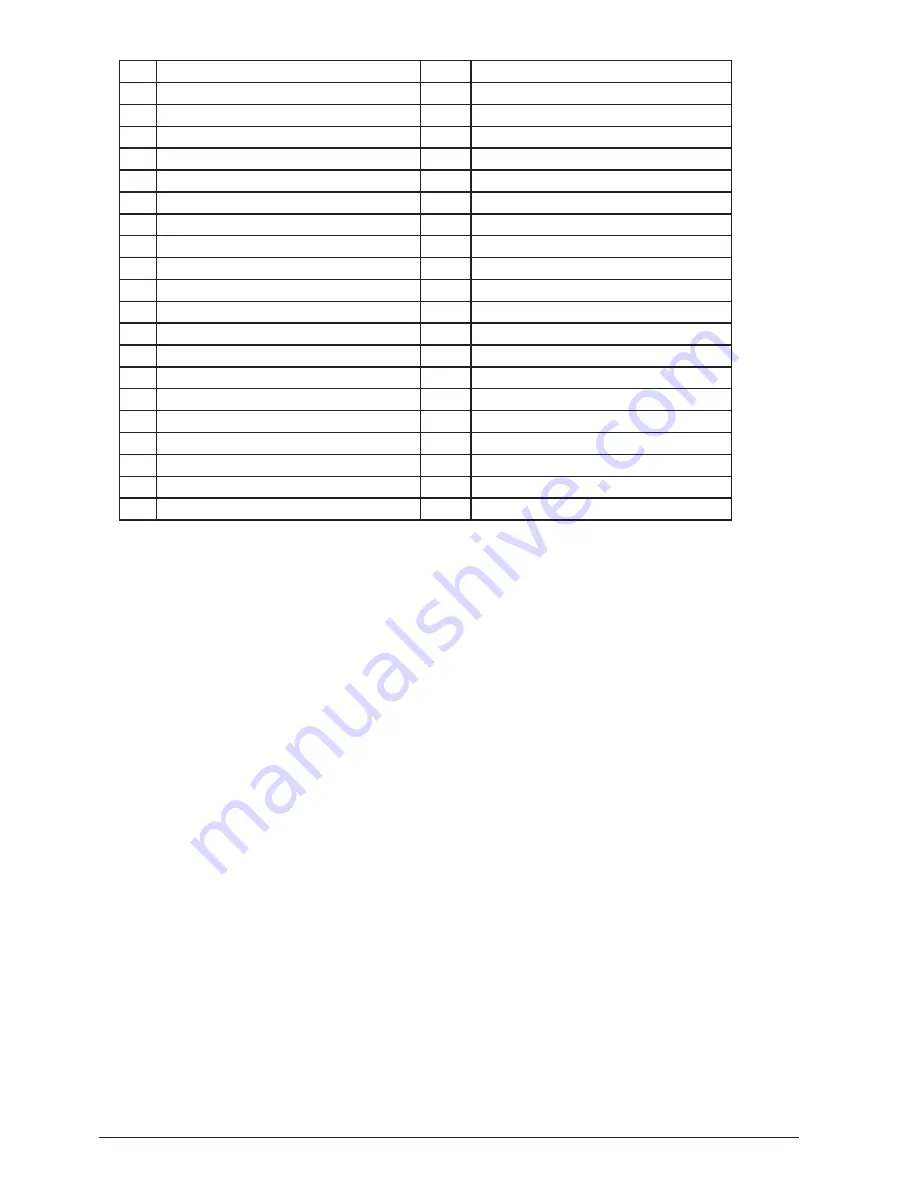

48

Handle

116

Center shaft

49

Sleeve fasten ring

117

Sleeve

50

Bearing 7206

e

118

Connect sheet

51

Bearing cover

119

Gear z33

52

O shape seal

120

Inner gear sheet

53

Oil cup

121

Connector

54

Taper head fasten screw

122

Key

55

Fixture sleeve

123

Gear z51

56

Key

124

Sleeve

57

Worm gear z28

125

Bearing 3056203

58

Sleeve

126

Gear z42

59

Small shaft

127

Fixture ring

60

Gear z17

128

Taper ring

61

Connection rod

129

Pin

62

Handle base

130

Arm

63

Handle ball

131

Shaft pin

64

Handle bar

132

Tape pin

65

Handle base

133

Handle

66

Pin

134

Spring

67

Elastic block ring

135

Steel ball

68

Washer

6. s

TrUcTUre

anD

aDjUsTmenT

The vertical column is mounted on the bottom base, loosen the fasten handle 63 ( fig.5 ) and rotate handle 17

( fig.2 ), the spindle box can move along the vertical column, loosen the fasten handle 63, the spindle box fixed

at any position, so to suit the different machining requirements, loosen cover nut 73 ( Fig.5 ) and rotate nut 72,

the swivel angle of the fasten handle can be adjusted and the tightness of the spindle box can also be changed,

when adjustment completes, fasten the cover nut.

The gear box is mounted on top of the spindle box, rotate the feed handle 89 ( Fig.5 ) the spindle will move up

and down along with the sleeve Remove the gear box, loosen the anti-motion washer 41 ( Fig.4 ), adjust nut 40,

the clea ance of the spindle bearing can be altered. The above adjustments have been set when put to shipment,

nonqualified personal is not allowed to de this adjustments.

7. T

ransmission

sysTem

The spindle rotate ( Fig. 6 ) through motor and gear 95;126 or 99;100 to shaft . Through gear 102; 123 or 108;119

to shaft. Through guide and transmission key to spindle. The motor has double- speed, through changing the

transmission gears, the spindle will rotate in 8 grades of speeds.

Spindle feed motion. The spindle feed movement is controlled manually, the handle 88 ( Fig.5 ) through gear,

gear rack transmission, to make the spindle sleeve move downwards so realise the feed motion.

The up and down motion of the spindle box. It is also controlled by hand, loosen the fasten handle 63 ( Fig. 5 ),

move handle 17 ( Fig.2 ), the spindle box will move up or down.

8. o

peraTion

Before start the motor, first rotate the change switch ( 21 ) on the spindle box till teach the required position (

high speed to “2R”, Low speed to “1R”, low speed and reverse direction to “1L” ) , then press down the start switch

“1” (green) ; for stop the machine press “O” button ( red ): for reverse rotation, fist to stop the machine and rotate

the speed change switch to “1L” or “2L” wait till the motor to stop completely and then press the start switch.

The speed selection is realised through handle 133 ( Fig.7 ), adjust handle 133 to realise 4 kinds of speed

variations, matched with double speed motor, we can gain 8 grades of speeds ranging from 100 rpm to 2900 rpm.

It should be noted that the speed variations could only be done when the machine has stopped so to avid any

possible damages to the gears and couplers.

About the drilling depth, you only need to adjust the nut 38 ( Fig.2 ) to the require dimension. The drill automatic

release applies to GB1443-85 (ISO 296-1974 ). Morse 3 outer taper with flat tail, its operation is 1:ke this: put out

the handle 48 ( Fig.4 ), rotate handle 88 ( Fig.5 ), then the sleeve will lead the drill to the highest position, the drill

end touches the enter shaft end so to be pushed out, then push 48 to its original position, install the tool.

Содержание HU 25 T

Страница 1: ...HU 25 T D R I L L I N G M M A C H I N E S...

Страница 5: ...5 CHANGES AND TYPING ERRORS RESERVED 5 Parts drawings and list Figure 1 Figure 2 Figure 3...

Страница 6: ...6 CHANGES AND TYPING ERRORS RESERVED Figure 4 Figure 5...

Страница 7: ...7 CHANGES AND TYPING ERRORS RESERVED Figure 6 Figure 7...

Страница 12: ...12 CHANGES AND TYPING ERRORS RESERVED...

Страница 13: ...13 CHANGES AND TYPING ERRORS RESERVED...

Страница 16: ...2014 V1...