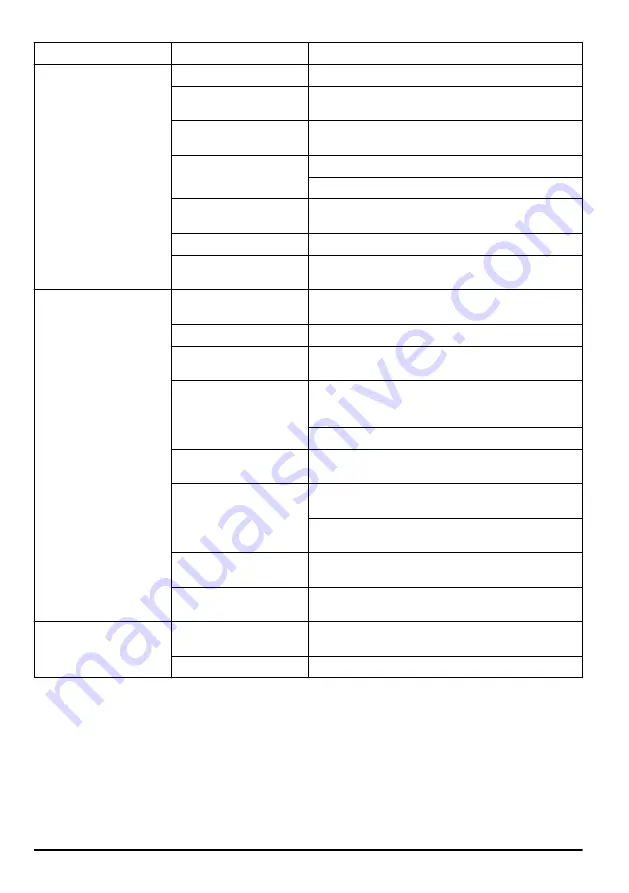

Problem

Cause

Solution

The air goes directly

through the exhaust or the

product vibrations are slow.

The rotor is blocked.

Shake the tube carefully when the tube is pressurized.

The air pressure is too low

to start the product.

Measure the air pressure. Refer to

page 10

.

The air flow is too low to

start the product.

Measure the air flow. Refer to

Technical data on page

10

.

There is a leak in the air

hose.

Attach the clamps correctly on the air hose.

Replace the air hose if it is necessary.

The product is not suffi-

ciently lubricated.

Lubricate the product. Refer to

on page 6

.

The lamella is worn out.

Replace the lamella.

The product is not attached

correctly.

Attach the product correctly. Refer to

.

The vibration of the con-

crete is not constant.

The centrifugal force is too

low.

Change to a product with more power.

The air exhaust is blocked. Remove the blockage. Clean the air exhaust.

The air pressure is too low. Measure the air pressure. Refer to

page 10

.

The product is not attached

correctly.

Attach the brackets correctly to the concrete form. Exam-

ine the bolts after 15 minutes of operation. Tighten the

bolts if they are loose.

Attach the product with the correct bolts to the brackets.

The number of products

used is not sufficient.

Add products were vibration is missing.

The correct product is not

used.

Attach high frequency products to a vertical concrete

form.

Attach lower frequency products to a horizontal concrete

form.

The air hose is too long.

Refer to the operator's manual for the air compressor for

correct length.

The concrete form is not

sufficiently rigid.

Make the concrete form more rigid.

The product does not oper-

ate correctly in a dusty en-

vironment.

There is sand or dust in the

product.

Disassemble and clean all the parts with fuel. Then lubri-

cate all parts and assemble the product.

The air exhaust is blocked. Remove the blockage. Clean the air exhaust.

8

1579 - 001 - 18.12.2020