GENERAL SAFETY PRECAUTIONS

16 – English

should be tensioned until it does not sag from the

underside of the bar.

- Tighten the bar nut using the combination spanner.

Check that the chain can be pulled round easily by hand.

Lubricating cutting equipment

Chain oil

•

Chain oil must demonstrate good adhesion to the

chain and also maintain its flow characteristics

regardless of whether it is warm summer or cold

winter weather.

•

As a chain saw manufacturer we have developed an

optimal chain oil which has a vegetable oil base. We

recommend the use of our own oil for both maximum

chain life and to minimise environmental damage.

•

If our own chain oil is not available, standard chain oil

is recommended.

•

In areas where oil specifically for lubrication of saw

chains is unavailable, ordinary EP 90 transmission oil

may be used.

•

Never use waste oil!

This is dangerous for yourself,

the machine and the environment.

Filling with chain oil

Fill with oil every hour or when the battery is flat.

Checking chain lubrication

•

Check the chain lubrication each time you refuel. Aim

the tip of the bar at a light coloured surface about 20

cm (8 inches) away. After 1 minute running at 3/4

throttle you should see a distinct line of oil on the light

surface.

What to do if lubrication does not work:

•

Check that the oil channels in the bar are not

obstructed. Clean if necessary.

•

Check that the oil channel in the gear housing is

clean. Clean if necessary.

•

Check that the bar tip sprocket turns freely. If the chain

lubrication system is still not working after carrying out

the above checks you should contact your service

workshop.

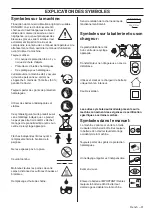

!

WARNING! Poor lubrication of cutting

equipment may cause the chain to snap,

which could lead to serious, even fatal

injuries.