18

– English

MAINTENANCE

Muf

fl

er with catalytic converter

A muf

fl

er

fi

tted with a catalytic converter reduces the extent of

the following substances in the exhaust fumes:

• Hydrocarbons (HC). Some hydrocarbons in gasoline and the

exhaust are carcinogenic.

• Nitric oxides (NO). Irritating for the breathing air-ways.

• Aldehydes. The most common formaldehyde, is carcinogenic

and causes hypersensitiveness.

NOTE! The level of carbon monoxide is not reduced. This is an

odourless and extremely poisonous substance. Therefore avoid

exposure without good air circulation.

The muf

fl

er is designed to

dampen the noise level and to

direct the exhaust fumes away

from the user. The exhaust

fumes are hot and can contain

sparks, which can result in

fi

re

if the exhaust fumes are di-

rected towards a dry or in

fl

am-

mable material. Some muf

fl

ers

are

fi

tted with a special spark

arrest screen. If your machine

is

fi

tted with this type of muf-

fl

er then the screen should be

cleaned at least once a week.

This is done using a wire

brush. If the screen is dam-

aged in anyway it should be re-

placed. If the screen is blocked

this will result in the engine

over heating and damage to the

cylinder and piston,

NOTE!

Never use a machine with a

defective muf

fl

er.

!

WARNING!

The coating on/in the catalytic element can

be hazardous to health if consumed. Wear

protective gloves when carrying out service

work on the catalytic converter.

WARNING!

Muf

fl

ers

fi

tted with catalytic converters

become extremely hot during use and after

stopping. This also applies at idling speeds.

Contact can result in burns to the skin. Be

observant to the risk of

fi

re!

!

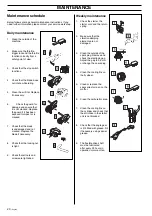

Cooling system

To maintain as low an

operating temperature as

possible the engine is

equipped with a cooling

system.

The cooling system consists of:

1. An air intake on the starter

unit.

2. Cooling

fi

ns on the

fl

ywheel.

3. Cooling

fi

ns on the cylinder

4. Cylinder cover (leads cold

air onto the cylinder).

Clean the cooling system using

a brush at least once a week,

in dif

fi

cult conditions more

often.

A dirty or blocked cooling

system leads to the engine

overheating resulting in

damage to the cylinder and

piston.

Spark plug

The condition of the spark plug

is affected by:

• An incorrect carburettor

setting.

• An incorrect fuel mixture (too

much or faulty oil).

• A dirty air

fi

lter.

These factors cause deposits

on the spark plug electrode

that may result in malfunction

or starting dif

fi

culties.

0,5 mm

If the machine is low on power, dif

fi

cult to start or runs

poorly while idling always check the spark plug

fi

rst before

taking any other action.

If the spark plug is dirty, clean it and at the same time check that

the electrode gap is 0.5 mm. The spark plug should be changed

after about one month of operation or earlier if necessary.

NOTE! Always use the recommended type of spark plug. An

incorrect spark plug can damage the cylinder/piston.

Содержание 325EX SERIES

Страница 24: ...2004W47 114 03 40 26 z HB 6 z HB 6 ...