21 HUSKYTOOLS.com

Please contact 1-888-43-HUSKY for further assistance.

Maintenance (continued)

REPLACING THE BELT

WARNING:

Serious injury or damage may occur if parts

of the body or loose items get caught in moving parts.

Never operate the unit with the belt guard removed. The

belt guard should be removed only when the air compressor

power is disconnected.

□

Turn the air compressor off, lock out the power

supply, and relieve all air pressure from the air

tank.

□

Remove the four screws from the belt guard (1).

The front belt guard can now be lifted up and

away from the unit.

□

Mark the pump position on the saddle.

□

Loosen the motor mounting screws and slide the

motor toward the air compressor.

□

Remove the belt (2) and replace with a new one.

□

See

Adjusting the Belt Tension

before tightening

the motor mounting screws.

ADJUSTING THE BELT TENSION

□

Slide the motor into the original position, line

the motor up with the mark made earlier on the

saddle.

□

Tighten the two outside motor mounting screws

enough to hold the motor in place for checking

the pulley and flywheel alignment.

□

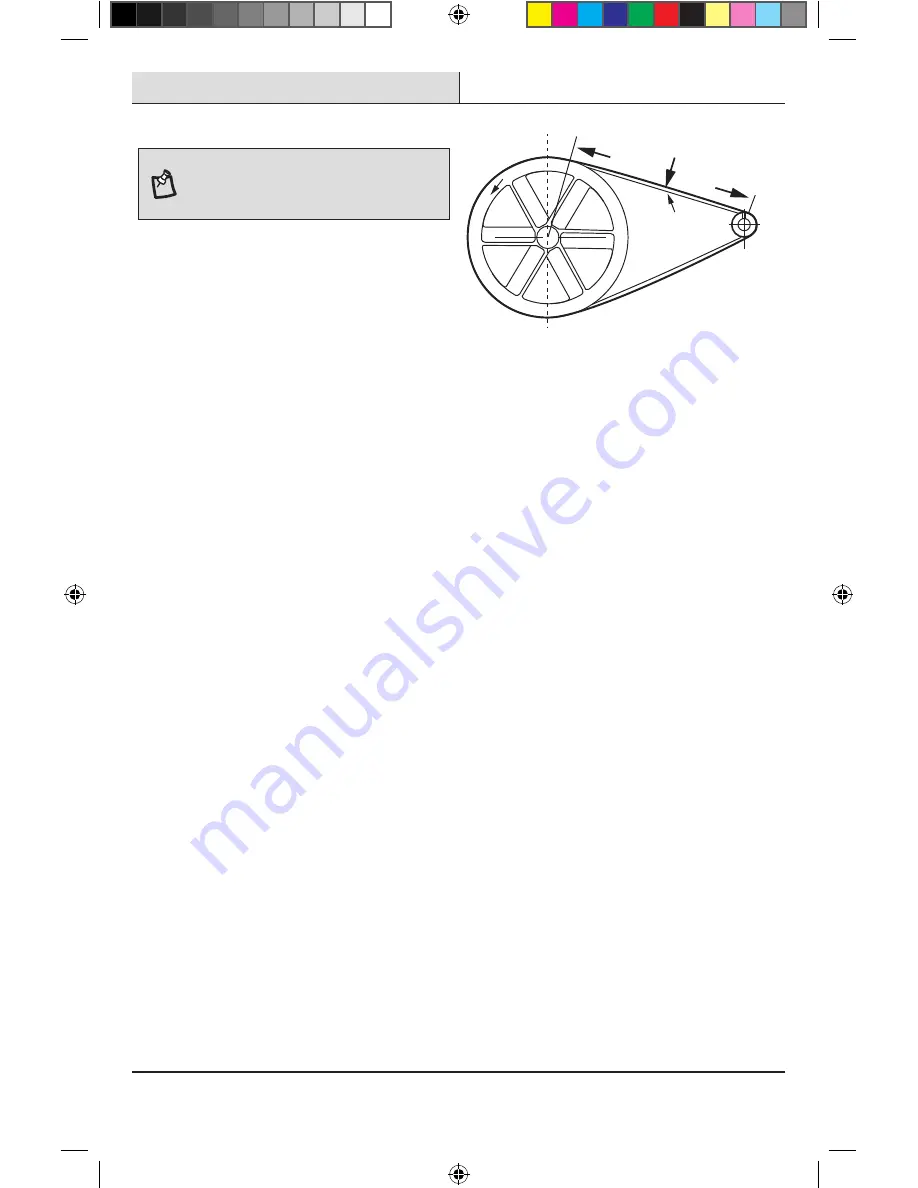

The belt should deflect 1/2 in. (12.7 mm) at

midway between the pulley and the flywheel

when a five-pound (2.26 kg.) weight is applied

at the midway point.

□

When proper belt tension is achieved, tighten all

four motor mounting screws. Torque to 15-20

ft-lbs. (20-27Nm).

Downw

ard For

ce

Deflection

NOTE:

Once the engine pulley has been moved from its

factory set location, the groves of the flywheel and pulley

must be aligned to within 1/16 in. (1.6mm) to prevent

excessive belt wear. Verify the alignment by performing the

following pulley and flywheel alignment.

C302H_HUSKY_manual_5-15-ENG.indd 21

6/10/15 12:05 PM