Page 1 of 8

Technical Bulletin:

Issue 3 – March 2014

Calibration of the Regulating Unit

on VARIAX

®

B & C Hub Fans

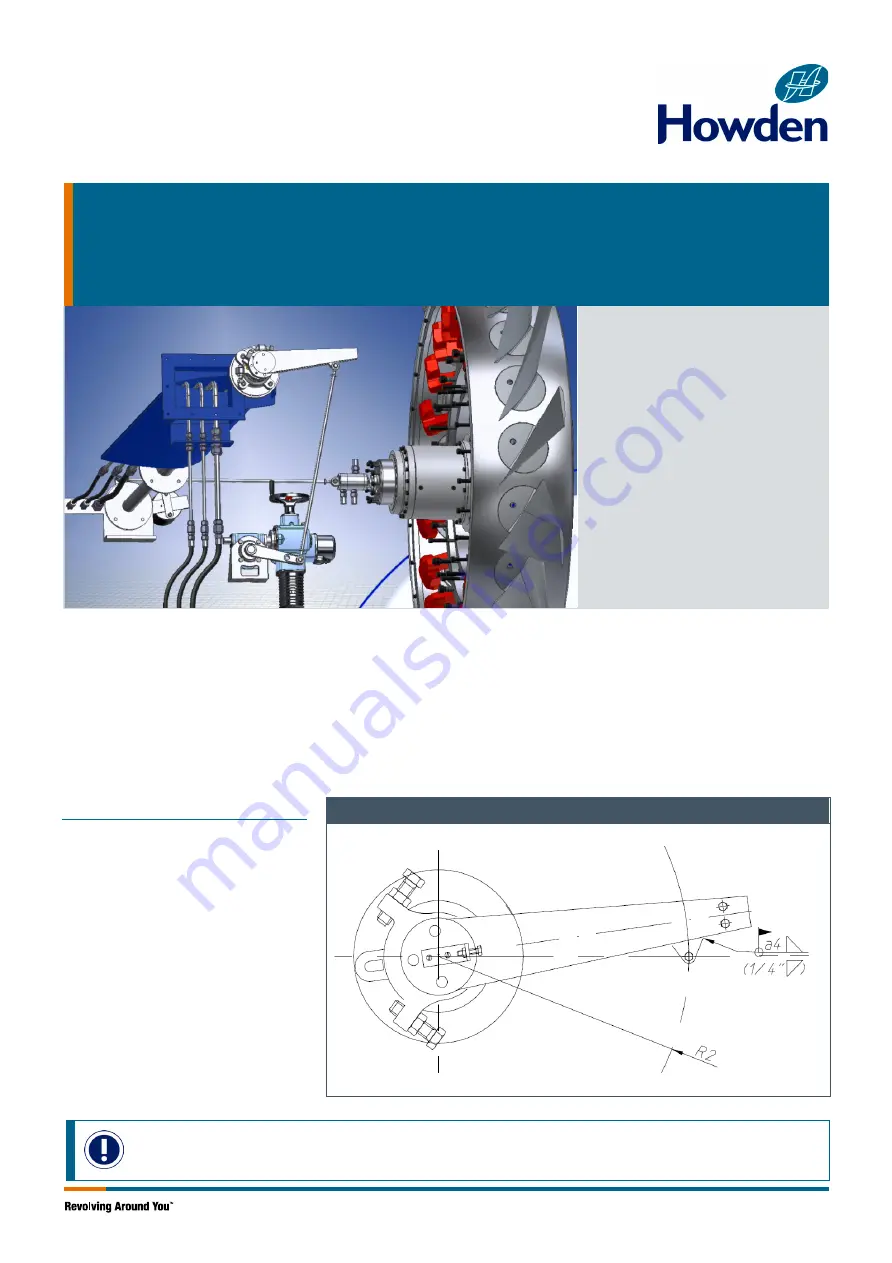

Internal and external

regulating parts –

schematic view

Howden has seen difficulties with the previous erection procedure for regulating

units on VARIAX

®

B & C Hub Fans. It is very important – especially for fans

operating in parallel – that the regulating units are mounted and calibrated correctly.

This procedure is implemented in all new erection and maintenance manuals edited after December 2013. The

procedure is valid for fans with Howden B- and C-hubs.

Verification Document V213351-9 (see pages 7/8/9).

3.20 Blade Pitch Actuator

The movement of the actuator lever is

transmitted to the external regulating arm of

the fan through a connecting rod. From the

external regulating arm the regulating

movements are transmitted to the hydraulic

regulating unit (hydraulic cylinder) through a

regulating shaft and a pull fork.

The position of the actuator in relation to the

regulating arm is designed so that the angular

motion of the actuator and the air volume are

almost linear.

1.

The pedestal for the actuator on the

side of the diffuser has been mounted

according to the drawing in chapter

10.00 of the Fan Manuals “Actuator

Arrangement”. Verify the location of

the bracket is correct in verification

document V213351-9.

Figure 1: Bracket on outer regulating arm

Notice:

All dimensions and angle given in this instruction are for reference only and the relevant project drawings must be

used when calibrating the regulating drive assembly.