2.5.3 MOTOR ROTATION CHECK

NOTICE

Pump rotation (three-phase only):

For three-phase

applications, check for proper pump rotation prior to

introducing fluid to the pump. Reverse rotation while

the pump is filled with fluid will cause pump seal failure.

Pump damage:

Do not run the motor/pump assembly

dry for more than a few seconds. Running a motor/

pump for a prolonged period without being completely

filled with fluid may cause damage to the pump seal.

The following procedures are for three-phase

applications only. Single-phase systems are prewired to

ensure the pump motor rotates in the correct direction.

1.

With main power connected to the heating system

motor

(see

SECOIO 2.5.1

)

, energize the pump

while observing the rotation of the pump motor fan

at the rear of the motor. Refer to rotation decal on

motor for correct rotation.

h

If the pump motor does not rotate in the correct

direction, disconnect power and switch any two

electrical leads at the main power terminal block

(

L1, L2, L3

). Reconnect power.

Repeat step 1

to

ensure motor rotates in the correct direction.

3

COMPONENTS AND

OPERATION

The following is an operational description for each of

the OLA interface and system components.

OOE:

Components installed in control box may

vary depending on the particular system

configuration purchased.

3.1

INTERFACE COMPONENTS

3.1.1 LOCAL/OFF/REMOTE SWITCH

•

local

– The system is

on

.

•

off

– The system is shut

off

.

•

remote

– The system will turn on and shut

off on a signal from the 24 V DC remote

connection.

See

SECOIO 2.5.2

.

3.1.2 PRIME BUTTON

Press and hold the

prime

button to energize the pump

motor in order to remove any air in the heating system

without energizing the elements.

OOICE!

Do not run

the motor/pump assembly dry for more than five

seconds at a time.

OOE:

The

prime

function is intended for use during

the first run procedure (

see

SECOIO 3.3.1

) or

after performing maintenance on the heating

system or plumbing (

see

SECOIO 4.2

)

.

3.1.3 RESET BUTTON

Press the

reset

button to reset the pump motor protection

switch without opening the control box. The reset function

is intended for use immediately following resolving and

repairing a system fault (

see

SECOIO 4.1.1)

.

3.1.4 PRESSURE/TEMPERATURE GAUGE

The OLA model features a temperature/pressure gauge

mounted at the heating tank inlet. The gauge will

indicate a pressure increase when the pump motor is

engaged by pressing and holding the

prime

button or

during normal operation. The gauge will also indicate the

fluid’s current temperature.

OOE:

Your system’s operating pressure may vary

depending on the configuration of the engine.

3.1.5 PRESSURE RELIEF VALVE

CAUTION

!

Pressure relief valve

: If the OLA heating system is for

use with a pressurized fluid system, additional, user-

supplied pressure relief must be installed along the

heating system outlet plumbing. User-supplied pressure

relief valve plumbing must be routed back to oil sump

or to atmospheric pressure. Do not route pressure relief

plumbing back to heating system tank.

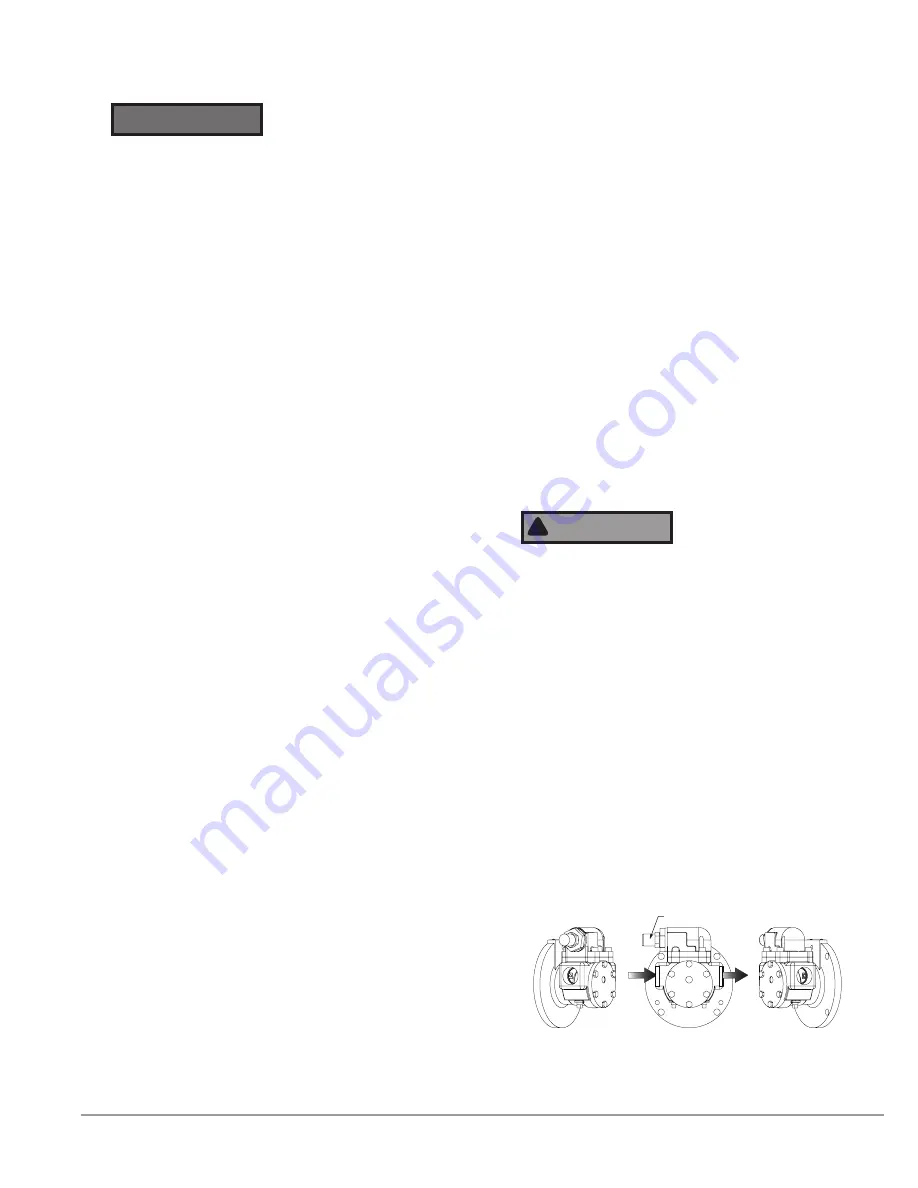

The oil pump pressure relief valve is internal to the pump

and releases pressure from the discharge side of the

pump to the suction side of the pump at 75 psi (525

kPa). No plumbing for this component is required. The

pressure relief valve cap must always point toward the

inlet side of the pump.

The OLA heating system is designed to not exceed 125

psi (862 kPa); however, the oil pump will not exceed

75 psi (517 kPa). In the event the pressure relief valve is

activated, the pump will continue to produce flow, but

will not exceed a pressure of 75 psi (517 kPa).

PRESSURE RELIEF

VALVE CAP

PUMP INLET

PUMP OUTLET

Figure 6. Typical OLA pump assembly. Note that the pressure relief

valve cap must always point toward the inlet side of pump.

Содержание OLA

Страница 2: ......

Страница 6: ...iv installation operation manual ola heating system this page intentionally left blank ...