MF

37

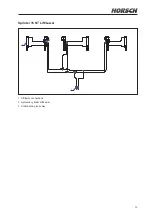

Distributor

Depending on the working width, the distributors

are fitted with a different number of seed and

fertiliser hoses.

Maintenance and inspections

¾

Check the distributor regularly for foreign

objects or blockage. Unscrew the distributor

cover and check the outlets.

¾

Check all components regularly for leak tightness.

¾

Check the correct order of the seed flow sensors.

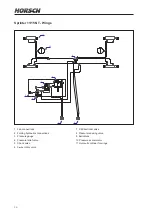

Seed flow control (option)

The seed hoses can be monitored with the seed

flow sensors.

The sensors are connected in series and the

numbers inform about the order.

In cases of an alarm, these sensor numbers help

when troubleshooting the hoses.

Hose installation

The outlets on the seed boxes are allocated to

the individual coulters through numbering.

NOTE

Uniform seed placement can only be ensured

when the seed transport to the coulters is working.

¾

Observe correct hose installation.

NOTE

¾

Outlets can be closed for double groove spac-

ing when drilling maize.

To this end, close all even-numbered (with

rectangular frame) or odd-numbered (with

round frame) outlets with the dummy plugs.

¾

Close the outlets tightly to prevent loss of air.

¾

Adjust the seed quantity in the

E-Manager

and

verify before drilling.

Dummy plugs to close outlets