15HMC0066 | 05/2015

Hornady Manufacturing Co. • P.O. Box 1848, Grand Island, Nebraska 68802-1848

308-382-1390 • 800-338-3220 • Fax: 308-382-5761 • Hornady.com/contact

680036

Insufficient swage may make primer

seating difficult and over-swaging could

damage the swage plate support stem or

the cartridge case.

NOTE:

The Lock-N-Load Primer Pocket

Swage is designed to swage the crimp

and not the entire primer pocket.

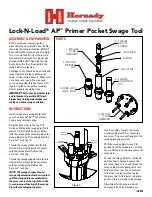

Continue this process, making

adjustments in 1/8 turn increments until

desired swage is achieved. The swage

punch assembly will eject the case from

the swage punch. If desired, you can use

a small amount of case lube on the swage

punch or on the primer pocket.

A properly swaged primer pocket will

have a small radius at the edge of the

primer pocket

(see photo below)

. It is

wise to set the swage for a minimal radius

and test by seating a primer in the case.

Adjust until enough swage is achieved to

seat a primer properly.

NOTE: If using lube, remove it before

priming as many lubes will contaminate

primers.

Once proper swage is achieved, thread

the swage adjust lock ring (9) down onto

the o-ring (8) to lock the swage adjust

screw position.

At this point, the press is set and ready

to swage the pockets. Start the process

by cycling the press and inserting

sorted, de-primed cases into the swage

alignment die

(station 4)

at the top of the

stroke. When the first case reaches the

swage die

(station 1)

, it will be swaged.

You will feel the cam-over of the press as

it’s swaging. Continue cycling the press.

When the first case reaches the stripper

die

(station 3)

, it will be lifted from the

swage plate support anvil. When the

second case reaches the stripper die, it

will push the first case out the top of the

die allowing removal

(Fig. B)

.

INSTRUCTIONS (CON’T)

Figure B

Insert

Remove

A properly swaged primer pocket.