WT8840 TRADE WATER HEATER CONTROLS

34-00013EF—01

6

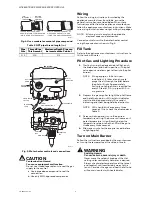

When the solid light is present, the pilot and

main valve will not hold. When the status

indicator goes out, the user can restart the

system. (Approximate shutdown time is one

minute.)

3.

After status indicator analysis and appliance

repair is complete, turn device knob to OFF, wait

until the indicator goes out, then perform

lighting procedure.

4.

Status indicator light should be in normal mode

(1 flash) with the knob in the PILOT position.

Turn the device knob past the water temperature

in the tank should turn on the main burner. The

Status indicator light will strobe every three

seconds when there is a call for heat.

5.

In the event of multiple failure codes, the next

failure code follows the previous failure code by

approximately three seconds with higher flash

count first.

*

LED Error Codes are flashed once per second, with a three-second pause between repeating the error code.

**

Maximum two different errors can be displayed simultaneously if more than one error has been detected.

Table 3. Troubleshooting with status light visual indication.

LED Error

Code

**

Number of LED Flashes

*

Detected Failure

Recommended Action

Normal

operatio

n. No

action

required.

1 flash

every 3

seconds

Not an error;

indicates the

electronics is holding

the Pilot Valve open

and the Main Valve

closed.

You can now turn the knob to a

desired setpoint temperature. LED

will continue to flash 1 time every 3

seconds while in Idle mode (no call

for heat).

Strobe

every 3

seconds

Not an error;

indicates call for heat

during normal

operation, Main valve

open.

None.

Action

required.

2 flashes

Low thermopile

voltage; main valve

not turned ON.

Check thermopile and its

connections. Check pilot flame.

4 flashes

Temperature cut-out

limit reached.

Check the valves and the water

temperature sensor. Reduce the

water temperature setpoint.

Thoroughly check out main valve

operation and water temperature

control before walking away.

5 flashes

Water temperature

sensor failure.

Check water temperature sensor

and its connection for open

circuits, shorts, or differences in

resistance between the two sensor

elements.

6 flashes

Tank leakage

detected by

accessory module.

Control recovers after receiving

message from accessory module.

7 flashes

Electronics Failure

Replace control module.

8 Flashes

This is just a warning;

The control does not

see power decaying

with the knob in the

OFF position.

Check valves.

Solid ON

Not an error—

indicates that the

control is in OFF

mode.

None; wait until LED turns off if you

want to restart the system.