2

DVI 980/982

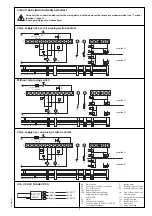

APPLICATION FEATURES

1. Information system

The information system is microprocessor based and reports

on all aspects of burner control box operation and flame

supervision. It informs continuously about the actual

programming sequence the unit is just performing. Besides

monitoring of the programming sequence it also allows to

identify errors during start-up of operation without any

additional testing devices. The automatically performed

diagnosis is a valuable tool which facilitates service/

maintenance work and therefore saves costs. The analyses

of the error cause can be done directly on stage or if not

possible afterwards as the lock out reason is stored in a

non-volatile lock out mode memory.

The information system communicates with the outside

world using a LED (the used Flash-Code is similar to the

Morse-Code). The messages are optically transmitted by a

appropriately flashing LED. Using an additional terminal

(optional), the messages can be recorded and displayed in

easy readable form.

1.1 Programming sequence display

The built-in microprocessor controls not only the program-

ming sequence but the information system too. The indivi-

dual phases of the programming sequence are

displayed as Flash-Code.

The following messages can be distinguished:

Message

Flash-Code

waiting for

❘ ❘

.

air proving switch

pre-purge

❘ ❘ ❘

.

tv1

pre-ignition

❘ ❘ ❘ ❘

.

tvz

safety time

❚ ❘

.

ts

delay 2nd stage

❚ ❘ ❘

.

tv2

running

❘

_

low mains voltage

❘ ❚ ❚

_

Internal fuse defect

❘ ❚

_

> control box defect

Description

❘

= short pulse

❚

= long pulse

. = short pause

_ = long pause

1.2 Lock-out diagnoses

In case of a failure the LED is permanently illuminated. Every

10 seconds the illumination is interrupted by a flash code,

which indicates the cause of the error. Therefore the following

sequence is performed which is repeated as long as the unit

is not reset.

Sequence:

illuminated phase

dark phase

Flash-Code dark phase

❘ ❚ ❚ ❚ ❚

for 10 sec

for 0.6 sec

for 1.2 sec

Error diagnosis:

Error message

Flash-Code

Possible fault

lock out

❘ ❚ ❚ ❚ ❚

within safety time

safety time

no flame establishment

stray light

❘ ❘ ❚ ❚ ❚

stray light

during monitored phase,

detector may be faulty

air proving switch

❚ ❚ ❘ ❘ ❘

air proving switch

in closed position

contact welded

air proving switch

❘ ❘ ❘ ❚ ❚

air proving switch does not

time-out

close within specified time

air proving switch

❘ ❘ ❘ ❘ ❚

air proving switch opens

opened

during start or operation

loss of flame

❚ ❚ ❚ ❚ ❘

loss of flame signal during

operation

Flash-Code for manual lock out

manual/external

❘ ❘ ❚ ❚ ❚

❚ ❚ ❚ ❚ ❚

lock out

(see also 3. lock out and reset)

Error RV1

❚ ❚ ❚ ❚ ❘ ❘ ❚ ❚ ❚ ❚

or STB opens

Safety temperature delimiter STB opens. For reset, the supply

line must, for a short time, be interrupted after pushing the reset

button.

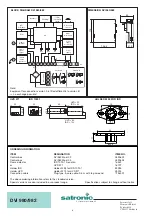

2. Flame detection

The following types of flame detectors are suitable:

– Ionisation probe, temperature resistant material, well

insulated (material and insulation same as for ignition

electrode).

– Infrared-flicker detector type IRD 1020.1 with mounting

flange M 93 or the UV solid state flame sensor UVD 971.

Flame detection using an ionisation probe is only possible

in conjunction with mains supplies which provides a neutral

earth connection.

Connecting the IRD 1020.1 or UVD 971 the correct wiring

has to be observed.

2.1 Stray light monitoring

The stray light check is performed at the end of the pre-

purge time for the duration as mentioned in the table of

timings.