3

60-2035—9

RA890G

SPECIFICATIONS • INSTALLATION

®

American Gas Association Design Certified For -20

°

F

(-29

°

C). Certificate no. 20-6b.

ACCESSORIES:

Models with 15 second safety switch: -20F (-29

°

C).

W136A Microammeter.

123514B Flame Simulator.

196146 Meter Connector Plug.

FSP1535 Test Panel: For operational check of the

RA890E,F,G,H,J or the R4795.

118702E Remote Reset Cover Assembly.

202471A Cover Assembly with reset button.

Installation

CAUTION

Ultraviolet sensing tubes have a life expectancy

of 40,000 hours of continuous use within the

ambient temperature and voltage ratings. Worn

out ultraviolet sensing tubes result in failure of the

sensing tube to properly discriminate between

flame conditions.

Systems using the RA890G with the C7027,

C7035 and C7044 Flame Detectors should only be

used on burners that cycle On and Off at least once

every 24 hours. Appliances with burners that re-

main on for 24 hours continuously or longer should

use the C7012E Flame Detector with the R7247C

Amplifier or the C7076A Flame Detector with the

R7476A Amplifier as the ultraviolet flame detec-

tion system.

WHEN INSTALLING THIS PRODUCT…

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced flame safequard

control technician.

4. After installation is complete, check out product op-

eration as provided in these instructions.

CAUTION

1. Disconnect power supply before beginning in-

stallation to prevent electrical shock and equip-

ment damage. All wiring must comply with ap-

plicable local electrical codes, ordinances, and

regulations.

2. Limits must be rated to carry and break current to

the ignition transformer, pilot valve (or first stage

oil valve), and main fuel valve(s) simultaneously.

3. All external timers must be Listed or Component

Recognized by authorities that have jurisdiction

for the specific purposes for which they are used.

Follow the burner manufacturer instructions when sup-

plied; otherwise, proceed as follows.

LOCATION

Temperature

Install the RA890G where the surrounding temperatures

remain within the ambient Operating Temperature Ratings

listed in the SPECIFICATIONS section.

Humidity

Install the RA890G where the relative humidity never

reaches the saturation point. Condensation of moisture on

the RA890G may cause enough leakage to short the flame

signal to ground and prevent the burner from starting.

Vibration

Do not install the RA890G where it could be subject to

excessive vibration. Vibration shortens the life of the elec-

tronic components.

Weather

The RA890G is not designed to be weathertight. If it is

installed outdoors, use a suitable weathertight enclosure.

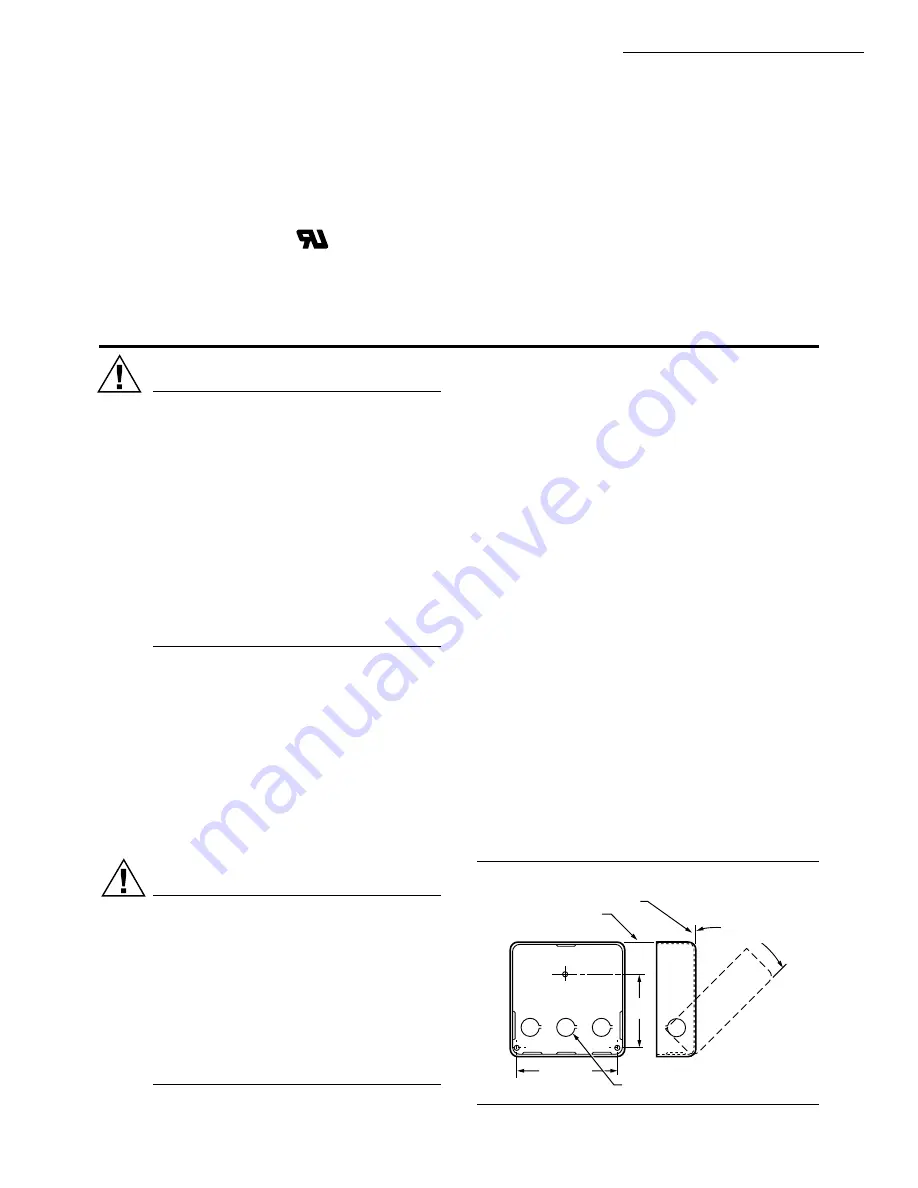

MOUNT SUBBASE

Locate subbase where ambient temperature is within the

specified rating.

Mount the subbase so that the top and bottom are hori-

zontal and the back is vertical. The subbase may lean

backward as much as 45 degrees if necessary. See Fig. 1.

Fig. 1—Mounting Subbase. in in. (mm)

M8681

HORIZONTAL

VERTICAL

2-7/8

(73.0)

4-1/8 (104.8)

KNOCKOUTS (9) FOR

1/2 IN. (13) CONDUIT

45 DEGREES

MAXIMUM LEAN

EXAMPLE: Pilot duty rating = 25 VA.

At 120V, running current is 25

÷

20 = 0.21A.

Maximum allowable inrush is10 times 0.21 = 2.1A.

UNDERWRITERS LABORATORIES INC LISTED: 120V

models only: File no. MP268, Guide no. MCCZ.

NOTE:All devices meeting UL component recognition

bear the following symbol:

Canadian Standards Associated Certified: 120 V models

only: File no. LR9S329

Factory Mutual Approved: Report no. 22013.

Содержание RA890G

Страница 11: ...11 60 2035 9 ...