ML6194, ML6294 NON-SPRING RETURN DIRECT COUPLED ACTUATORS

5

63-2511—1

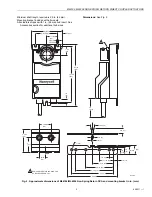

Fig. 3. Installing mounting bracket on ML6194/ML6294

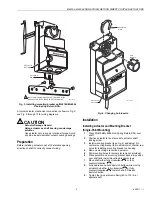

Non-Spring Return DCA.

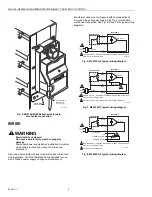

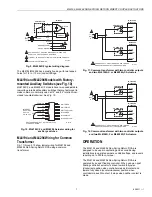

A typical actuator mechanical connection is shown in Fig. 5;

see Fig. 6 through 13 for wiring diagrams.

CAUTION

Actuator Damage Hazard.

Using actuator as shaft bearing can damage

actuator.

Use actuator only to supply rotational torque. Avoid

any side loads to actuator output coupling bearings.

Preparation

Before installing actuator on shaft, determine opening

direction of shaft to correctly connect wiring.

Fig. 4. Changing hub inserts.

Installation

Installing Actuator and Mounting Bracket

(Single-Point Mounting)

1.

Place ML6194/ML6294 Non-Spring Return DCA over

shaft.

2.

Position actuator for best access to actuator shaft

locking screw.

3.

Install mounting bracket (see Fig. 2) and adjust it to

center mounting bracket tab in actuator slot. Mark screw

holes for installing mounting bracket on housing.

4.

Remove mounting bracket and actuator.

5.

Drill mounting holes for screws (screws not provided).

6.

Place actuator and mounting bracket back into position

over shaft and install mounting bracket screws.

7.

Move shaft either fully clockwise

or fully

counterclockwise

.

8.

Fully depress and hold declutch button while moving

actuator hub either fully clockwise

or fully

counterclockwise

to match shaft. Release

declutch button.

9.

Tighten the two set screws firmly (80 to 100 lb-in.)

against shaft.

M11271A

ACTUATOR

SLOT

DECLUTCH

BUTTON

INSTALL MOUNTING BRACKET SO THAT MOUNTING

BRACKET TAB IS CENTERED IN ACTUATOR SLOT.

1

1

30

30

0

60

60

90

M11272A

DECLUTCH

BUTTON

HUB

INSERTS

RETAINING

RING