HM700A1000

19

33-00118—01

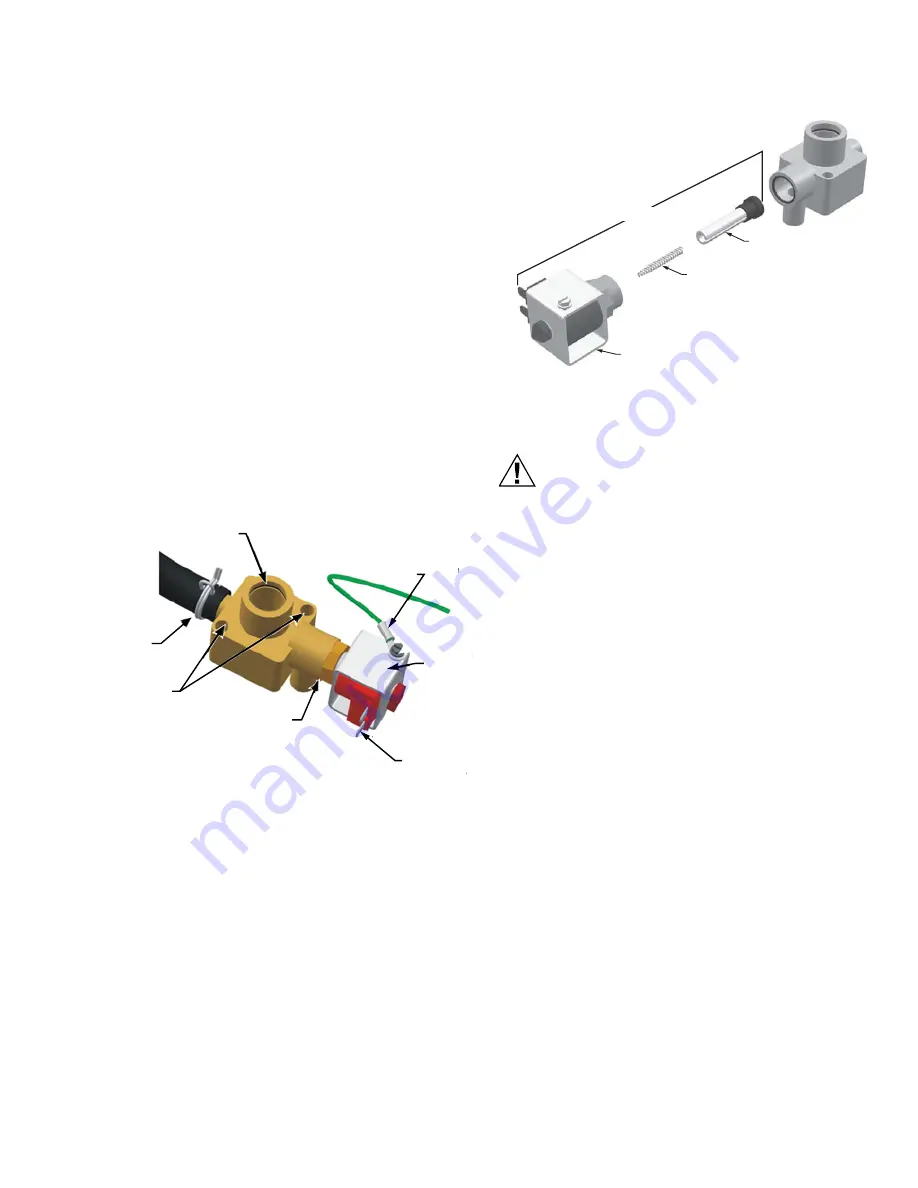

Drain Valve Cleaning

Always clean the drain valve before installing a new cylinder.

Scale from the spent cylinder may have fallen into the drain

valve and could prevent its proper operation. To properly clean

the drain valve it must be removed and disassembled.

1.

Disconnect spade terminals from the drain valve.

2.

Remove the two screws holding the valve to the drain

pan.

3.

Squeeze the tabs of the spring clamp holding the hose

to the drain valve and slide it up the hose. Pull hose

from drain valve. Lift the drain valve from the drain pan.

4.

Unsnap red coil cap on solenoid and remove the sole-

noid from the valve.

5.

Loosen brass nut holding actuator to plastic housing

with a wrench and disassemble actuator.

6.

Clean actuator components and valve housing (inlet

port, outlet port, and cylinder port). Put new o-ring that

was supplied with new cylinder into valve.

7.

Reassemble actuator making sure tapered end of

spring is oriented as shown in Fig. 24. Tighten brass nut

1/4 turn past hand tight.

8.

Clean out end of hose and reattach to valve. Slide hose

clamp back in place and place valve into drain pan.

9.

Secure valve with 2 screws to drain pan.

Fig. 23. Drain valve.

Fig. 24. Drain valve actuator assembly.

Installing the New Cylinder

CAUTION

Make sure the new cylinder is a HM700ACYL2. Use

of any other model or remanufactured cylinders

will void the HM700 warranty.

1.

Insert cylinder into drain valve. Tilt cylinder forward and

fit end of steam hose to steam outlet. Tip cylinder back

into place.

2.

Tighten hose clamp being careful not to over tighten and

crush the plastic cylinder steam outlet.

3.

Attach color-coded cylinder plugs to the corresponding

color-coded cylinder pin. Push down completely.

Connect high water sensor plug. Spring-loaded plugs

should fit snuggly onto the cylinder pin. Replace if they

are loose or damaged.

4.

Re-fasten tie strap.

5.

Replace the humidifier cover and secure with two

screws.

6.

Turn on power to humidifier with the external

disconnect.

7.

Open supply water shut off valve.

8.

Turn the humidifier On/Off /Drain switch to On.

CYLINDER PORT

AND O-RING

GROUND

WIRE

SOLENOID

SPADE

CONNECTORS

BRASS NUT

(ACTUATOR)

SCREWS

HOSE AND

HOSE CLAMP

MCR35700

M35707

SLEEVE AND

SOLENOID

SPRING

(NOTE ORIENTATION)

PLUNGER

ACTUATOR

Содержание HM700A1000

Страница 26: ...HM700A1000 33 00118 01 26 ...

Страница 27: ...HM700A1000 27 33 00118 01 ...