W

innox · Edition 12.20

EN-9

step 6 - Verify settings

1

With burner lit, drive control motor to high fire.

2

Wait for the chamber to reach normal operating conditions (e.g.

chamber temperature, process flows, etc.).

3

Measure high fire fuel using fuel flow measurement device. Com-

pare this to the rated high fire which can be found in the page

10 (Technical data).

4

Measure high fire air differential pressure between Tap

C

and the

chamber.

To chamber

Manometer

Tap C

Verify pressure settings

5

Compare this pressure to the chart: page 13 (Air ΔP vs. Input).

6

Drive the control motor to low fire and verify low fire flame signal

and flame appearance (if viewing).

7

Cycle burner from high to low several times to check repeatabil-

ity of settings.

8

Readjust burner if the settings do not repeat as expected. If nec-

essary, refer to page 10 (Assistance in the event of malfunction).

9

Use the System Schematics, see Technical Information Winnox,

to record all setup data as an aid for future troubleshooting and

setup operations.

CAUtIon

– Do not turn the combustion air blower off until the chamber

temperature is below 250°F (121°C). This will prevent hot

gases from back flowing into the burner and blower causing

damage to the burner.

10

Stop the burner.

MAIntenAnCe

Preventive maintenance is the key to a reliable, safe and efficient

system. The core of any preventive maintenance system is a list of

periodic tasks. The following are suggestions for a monthly list and

a yearly list.

➔

The monthly list and yearly lists are an average interval. If your

environment is dirty, the intervals may be shorter.

Monthly checklist

1

Inspect flame-sensing devices for good condition and cleanliness.

2

Check for proper inlet air/gas ratios.

3

Test all the alarm systems for proper signals.

4

Check ignition spark plugs and proper gap.

5

Check valve motors and control valves for free, smooth action

and adjustment.

6

Check for proper operation of the ventilating equipment.

7

Test the interlock sequence of all safety equipment; manually

make each interlock fail, noting that related equipment closes or

stops as specified by the manufacturer.

8

Test flame monitoring control system by manually shutting off gas

to burner.

9

Test main fuel hand-valves for operation.

10

Clean or replace the combustion air blower filter.

11

Inspect and clean the combustion air blower rotor.

Yearly checklist

1

Test (leak test) safety shut-off valves for tightness of closure.

2

Test air pressure switch settings by checking switch movements

against pressure settings and comparing with actual impulse

pressure.

3

Visually check ignition cable and connectors.

4

Inspect impulse piping for leaks.

5

Clean and inspect all the burners.

6

Make sure that the following components are not damaged or

distorted:

– burner nozzle

– spark plugs

– flame sensors

– flame tube or combustion block

7

If applicable, remove and clean all the orifice plates.

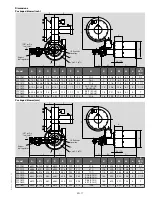

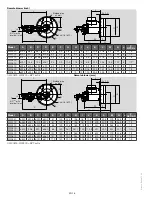

Burner nozzle

A

B

Component inspection

The nozzle can be inspected without removing the burner from the

chamber wall or entering the chamber. See the figures and perform

the following:

1

Shut the burner off and manually close the main gas shut off

cocks.

2

Allow the chamber temperature to cool down to 250°F (121°C).

3

Disconnect the gas piping at a union or the gas inlet flange

A

provided on the burner.

4

Remove the four bolts

B

.

CAUtIon

– Do not attempt to remove the rear cover by removing the inner

circle bolts

e

. Internal burner parts will be damaged.

5

Remove bolts

F

.

6

Remove the rear cover / nozzle assembly

C

from the burner

housing

D

.

7

To reassemble, follow this sequence in the reverse order.

note:

The combustor can be inspected only by removing the burner

from the chamber wall or entering the chamber.

C

D

E

F

Nozzle inspection