Maintenance

21

Cleaning the air cleaner

1. Paper element

Tap the element several times on a hard surface to remove excess dirt, or blow

compressed air (not exceeding 207kPa or 30psi) through the filter from the inside. Never

try to brush off dirt; brushing will force dirt into the fibres. Replace the paper element if it is

excessively dirty.

2. Foam element (All models except HRU19RPU & HRU19DPU).

Wash the element in a solution of household detergent and warm water, then rinse thoroughly,

or wash in nonflammable or high flash point solvent. Do not use fuel as a cleaning solvent

because this will create a risk of fire or explosion. Allow the element to dry thoroughly.

Soak the element in clean engine oil and squeeze out the excess oil. The engine will smoke

during initial start-up if too much oil is left in the foam, or the oil could saturate the paper element

making the engine inoperable.

3.

Wipe dirt from the air cleaner body and cover using a moist rag. Be careful to prevent dirt

from entering the air duct that leads to the carburetor.

4.

Reinstall the air cleaner element(s), and make sure the element(s) are properly positioned.

Install the air cleaner cover and clip in or tighten the screws securely.

Spark plug

Recommended spark plug:

NGK BPR5ES

for the following models: HRU196PU, HRU196DPU, HRU216SU & HRU216DSU.

NGK BPR6ES

for the following models: HRU19RPU, HRU19DPU, HRU197PU,

HRU197DPU & HRU217DPU.

For good performance, the spark plug must be properly gapped

and free of deposits.

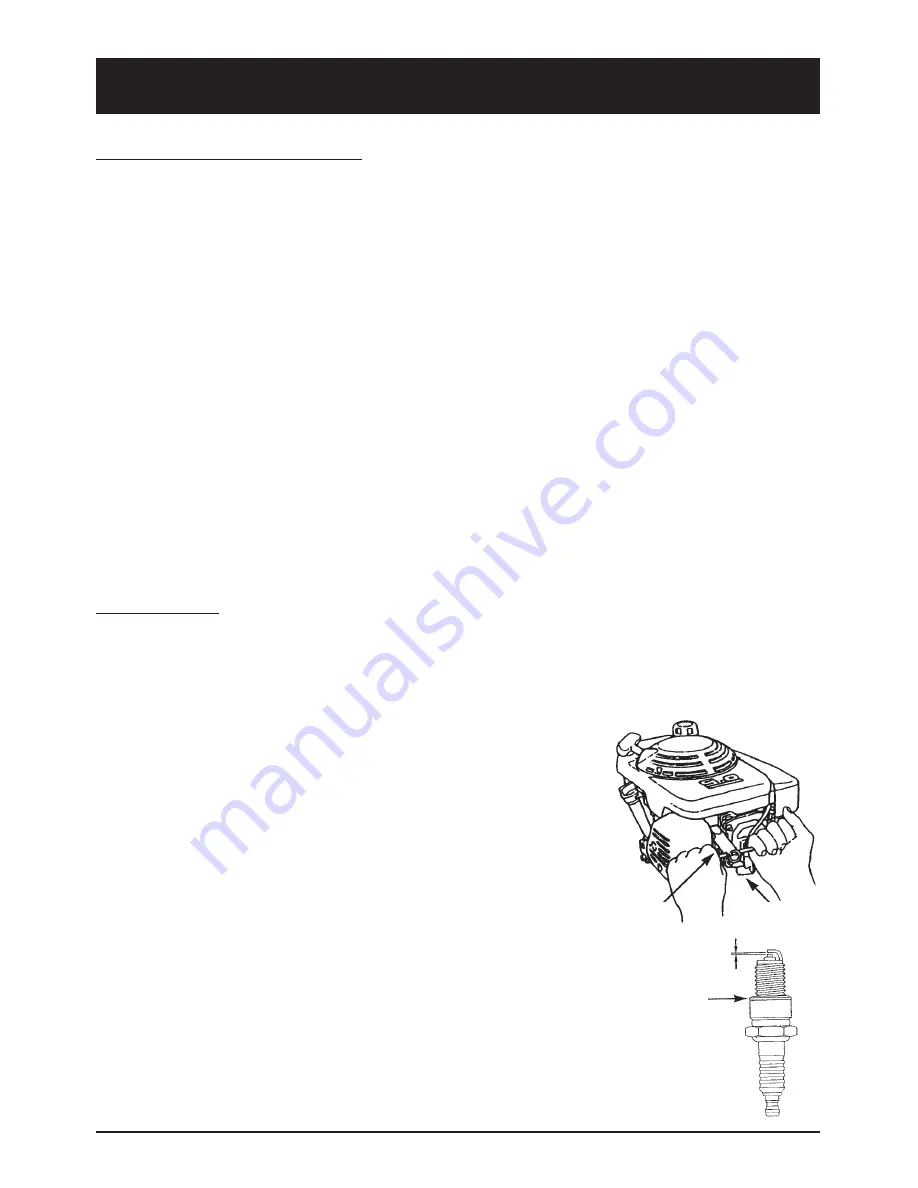

1. Disconnect the cap [1] from the spark plug, and remove any dirt

from the spark plug area.

2. Use the proper size plug wrench [2] to remove the spark plug.

3. Inspect the spark plug. Replace it if damaged, badly fouled, if the

sealing washer is in poor condition, or if the electrode is worn. If

the spark plug is to be reused, clean it with a wire brush.

4. Measure the electrode gap with a suitable gauge. The correct

gap is 0.70-0.80mm. If adjustment is needed, correct the gap by

carefully bending the side electrode.

5. Install the spark plug by screwing it in by hand until seated, then

tighten a further quarter turn with a spark plug spanner.

0.028 ~ 0.031 in

(0.70 ~ 0.80 mm)

SEALING

WASHER

[1]

[2]