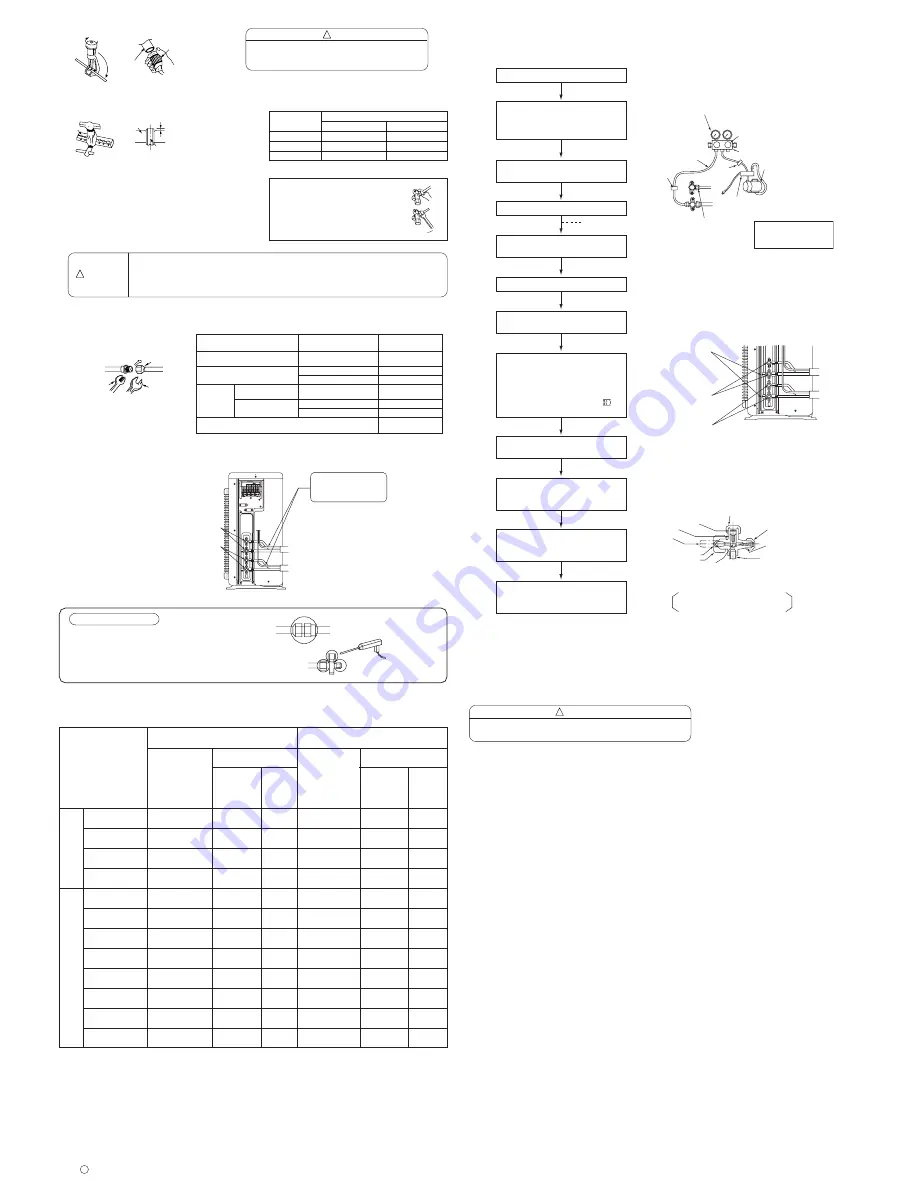

4. Preparation of Pipe

●

Use a pipe cutter to cut the copper pipe.

●

Before flaring, please put on the flare nut.

Outer

Diameter (Ø)

6.35 (1/4”)

9.52 (3/8”)

12.7 (1/2”)

Imperial flaring tool

0

~

0.5mm

0

~

0.5mm

0

~

0.5mm

Rigid flaring tool

A (mm)

●

Please use exclusive

tool

Copper

pipe

Trimming tool

A

Die

Die

Copper pipe

1.0mm

1.0mm

1.0mm

Wrench

Torque

wrench

Flare nut

Outer diameter of pipe (Ø)

Torque N·m (kgf · cm)

Small diameter side

●

Please be careful when bending the copper pipe.

●

Screw in manually while adjusting the center. After that, use of torque wrench to tighten the connection.

Large diameter side

6.35 (1/4”)

13.7-18.6 (140-190)

9.52 (3/8”)

34.3-44.1 (350-450)

12.7 (1/2”)

44.1-53.9 (450-550)

Small diameter side

Large diameter side

6.35 (1/4”)

19.6-24.5 (200-250)

9.52 (3/8”)

19.6-24.5 (200-250)

12.7 (1/2”)

29.4-34.3 (300-350)

Valve head

cap

12.3-15.7 (125-160)

Valve core cap

Connecting cord should

have arranged with piping

using tape previously.

Pipe connection port for Indoor unit No. 1

Pipe connection port for Indoor unit No. 2

Indoor unit No. 1

Indoor unit No. 2

CAUTION

!

●

In case of removing flare nut of a indoor unit, first remove a nut of small diameter side, or seal cap of large

diameter side will fly out. Free from water into the piping when working.

●

During connection, keep away from water.

●

Be sure to tighten the flare nut to the specified torque using a torque wrench. If the flare nut is tightened

excessively, it may crack as time elapses, causing refrigerant leakage.

●

Install the unit in a stable place to minimize vibration or noise.

●

After arranging the cords and pipes, secure them in place.

ONE UNIT

TWO UNITS

POSSIBLE COMBINATIONS

TO OPERATE

AMPERE

(A)

220-240V

CAPACITY RATING

(kW) (RANGE)

POWER

CONSUMPTION

(W)

ONE UNIT : The values indicated are only for one unit operation when two indoor units are connected.

OUTDOOR UNIT

COOLING

AMPERE

(A)

220-240V

CAPACITY RATING

(kW) (RANGE)

POWER

CONSUMPTION

(W)

OUTDOOR UNIT

HEATING

(Reference value)

COOL/HEAT CAPACITY SPEC, FOR INDOOR UNITS COMBINATIONS

Gas leakage inspection

Please use gas leakage detector to check if leakage occurs

at connection of flare nut as shown on the right.

If gas leakage occurs, further tighten the connection to stop

leakage. (Use the detector provided for R410A)

Lo

Hi

Vacuum for more

than 10 min.

Stop valve

Charge hose

Stop

valve

Vacuum pump adapter

Be sure the stop valve

is always fully opened.

Valve cap

Valve cap of valve core

Valve cap

Valve cap

Valve core

Valve cap of

valve core

Stopper

O-Ring

Pipe

Pipe

Seal cap

Flare nut

Spindle

Meter showing pressure

When the meter reaches -101KPa (-76cmHg) during

pumping, fully tighten the shuttle.

Air purging by vacuum pump

Closed

Vacuum pump

R410A Manifold valve

When pumping starts,

slightly loosen the flare

nut to check of air

sucked in. Then tighten

the flare nut.

The refrigerant channel is opened so

that the refrigerant will flow from the

outdoor unit into the indoor unit.

Remove the valve cap of valve core.

Run the vacuum pump.

Stop the vacuum pump.

Connect the charge hoses to the

vacuum pump and the charge port of

the valve core large dia. pipe side

service valve, respectively.

Remove the valve cap from the

spindle of the service valve.

Disconnect the charge hose from the

service valve.

Tighten the valve cap of valve core.

[Torque 12.3 - 15.7 N

¥

m (125 - 160

kgf

¥

cm)]

Attach the valve cap to the spindles

of each large and small dia. pipe

side service valves.

Tighten the valve cap of the spindle.

[Torque 19.6 - 24.5 N

¥

m (200 - 250

kgf

¥

cm)]

Turn the spindles of each large and

small dia. pipe side service valves

full counterclockwise until they are

securely tightened. Then retighten

them more than 10 degrees [using a

hexagon wrench key (4mm )

without fail].

Fully open the LO knob of the

manifold valve.

Close the LO knob of the manifold

valve.

Tighten all the way by hand.

Do not tighten all at once, but tighten it while

fitting the flared surface to the pipe.

CAUTION

!

5. Pipe Connection

5.1 Pipe connection

Connecting the pipe to outdoor unit

(1) Remove the flare nut and seal cap from the service valve.

(2) Apply refrigerator oil to the service valve and the flared portion

of the pipe.

(3) Using a wrench, security tighten.

●

Jagged edge will cause leakage.

●

Point the side to be trimmed downwards during trimming to

prevent copper chips from entering the pipe.

7. Operation test

●

Please ensure that the air conditioner is in normal operating condition during the operation test.

●

Explain to your customer the proper operation procedures as described in the user’s manual.

●

If the indoor unit does not operate, check to see that the connections are correct.

CAUTION

●

Trial run should be conducted on one unit at a time to check for incorrect

wiring of connecting cord.

!

6. Removal Of Air From The Pipe And Gas Leakage Inspection

6.1 Air purging by using vacuum pump

Fig. 6-1

Fig. 6-2

Fig. 6-3

<

I920: A

>

1.8

2.5

3.5

5.0

1.8 + 1.8

1.8 + 2.5

1.8 + 3.5

1.8 + 5.0

2.5 + 2.5

2.5 + 3.5

3.5 + 3.5

2.5 + 5.0

1.80

(1.00 – 2.50)

2.50

(1.00 – 2.80)

3.50

(1.00 – 3.90)

5.00

(1.00 – 5.60)

1.80 + 1.80

(1.50 – 4.00)

1.80 + 2.40

(1.50 – 4.60)

1.70 + 3.30

(1.50 – 5.60)

1.40 + 4.00

(1.50 – 5.90)

2.50 + 2.50

(1.50 – 5.60)

2.17 + 3.03

(1.50 – 5.70)

2.70 + 2.70

(1.50 – 5.90)

1.80 + 3.60

(1.50 – 5.90)

2.6 – 2.4

3.6 - 3.3

5.3 – 4.9

8.2 – 7.5

5.5 – 5.0

6.0 – 5.5

7.6 – 6.9

8.2 – 7.6

7.6 – 6.9

7.9 – 7.3

8.2 – 7.6

8.2 – 7.6

3.4 – 3.2

5.3 – 4.8

7.1 – 6.5

11.0 – 10.1

6.7 – 6.1

8.4 – 7.7

9.2 – 8.4

9.4 – 8.6

9.3 – 8.5

9.5 – 8.7

9.7 – 8.9

9.7 – 8.9

560

(200 – 750)

780

(200 – 980)

1160

(200 – 1280)

1780

(200 – 1960)

1190

(200 – 1300)

1310

(200 – 1450)

1650

(200 – 1820)

1795

(200 – 1980)

1650

(200 – 1820)

1730

(200 – 1900)

1795

(200 – 1980)

1795

(200 – 1980)

2.50

(1.10 – 3.20)

3.90

(1.10 – 4.70)

4.80

(1.10 – 5.80)

6.50

(1.10 – 7.20)

2.50 + 2.50

(1.50 – 5.20)

2.40 + 3.80

(1.50 – 6.30)

2.30 + 4.50

(1.50 – 7.20)

2.00 + 5.00

(1.50 – 7.20)

3.40 + 3.40

(1.50 – 7.20)

3.15 + 3.85

(1.50 – 7.20)

3.60 + 3.60

(1.50 – 7.20)

2.70 + 4.50

(1.50 – 7.20)

750

(200 – 1050)

1145

(200 – 1380)

1550

(200 – 1870)

2400

(200 – 2660)

1460

(200 – 1550)

1820

(200 – 1920)

1995

(200 – 2100)

2050

(200 – 2100)

2015

(200 – 2110)

2070

(200 – 2110)

2110

(200 – 2110)

2110

(200 – 2110)