11

English

䡬

Place the nailer vertically over the location into which

the nail is to be driven.

䡬

Do not drive nails directly into C-beam steel or attach

wire mesh laths, galvanized steel etc. directly onto it.

䡬

Do not use the nailer on roofs or ceilings.

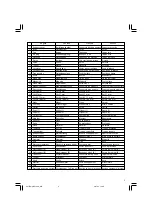

[Selecting hardened nails for steel plating]

CAUTION

Make sure that the length of the hardened nails

designed for use with steel plating is of the correct

thickness for the C-beam steel.

If the nail is too long for the material, the nail cannot

be driven enough into the C-beam steel and it may

result in bent nails, personal injury or accident.

Refer to the following figure to select the correct nail

length.

[Selecting Nail Length]

NOTE:

䡬

Holding power will be greatly decreased if nails are

driven too hard into steel plating, adjust the driving

depth of the nail by the adjuster.

䡬

There are cases in which the nails will not be driven

in sufficiently depending on a combination of the

hardness and thickness of the C-beam or material.

4. Driving nails into concrete

CAUTION

䡬

Use hardened nails designed for use with concrete.

䡬

Place the nailer vertically over the location into which

the nail is to be driven.

䡬

Do not drive nails directly into concrete or attach

metal plates directly onto it.

䡬

Do not drive nails into the edge of concrete.

䡬

Do not use the nailer in locations from which other

items are suspended (suspended pipes, etc.).

NOTE:

Only use the nailer on concrete that has not yet set,

soon after it has been poured.

Using the nailer on hardened concrete may result in

bent nails and nails being insufficiently driven in.

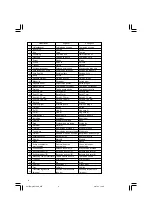

[Selecting hardened nails for use with concrete]

Select nails with a concrete intrusion depth of between

10 to 15 mm.

Reference Examples

NOTE:

The nails will not be driven in sufficiently if the

concrete intrusion depth is deeper than 15 mm.

5. Adjusting the nail-driving depth

CAUTION

When making adjustments, be sure remove your

finger from the trigger. When making adjustments,

be sure that the nail outlet is not facing downward

and that body parts or other people are not in the

path of the nail outlet.

䡬

Adjusting the adjuster (

Fig. 12

)

Carry out test driving. If the nails are too deep, turn

the adjuster to the shallow side (

mark).

If the nail depth is too shallow, turn the adjuster to

the deep side (

mark) (See

Fig. 12, 13

).

Depth is changed 1 mm with each rotation of the

adjuster.

NOTE:

䡬

When adjusting the adjuster, it does not rotate more

than 3 mm from the deepest point where a nail goes

down. Do not rotate the adjuster by force beyond

that point.

䡬

The nail-driving depth can also be adjusted by

changing the air pressure used. Carry this out together

with movement of the adjuster. Using a high air

pressure that does not match the nail-driving

resistance will shorten the life of this nailer.

6. How to use nosecap

CAUTION

Remove the hose from the nailer and release the

compressed air before installing or removing the

nosecap to prevent accidental nail ejection.

䡬

Attach the nose cap on the tip of the push lever when

you wish to protect the surface of wood, etc., from

scratches.

(1) Attaching and detaching nose cap

The nose cap can be attached by simply pressing it

into the push lever.

Press it in until a convex part inside the nose cap

enters into a hole of the push lever. (

Fig.14

)

For removal, insert a thin rod such as a screw driver

into the gap on the back of the push lever, and then

pull it out.

C-beam Steel

(Thickness: 1.6 mm to a

maximum of 3.2 mm)

Material Thickness

Approximately

10 to 35 mm

The external material

and steel plating is not

deformed.

The external material

and steel plating is

deformed.

Material Thickness

Nail Length

15 to 45 mm

50 mm

22 to 47 mm

57 mm

30 to 55 mm

65 mm

Length of Nails

to be Used

Wood Thickness

Concrete Intrusion

Depth 10 to 15 mm

Wood

Length of Nails

Concrete

Thickness

to be Used

Intrusion Depth

35 mm

50 mm

Approx. 15 mm

45 mm

57 mm

Approx. 12 mm

50 mm

65 mm

Approx. 15 mm

01Eng_NV100H_WE

3/27/12, 14:05

11