--- 45 ---

(2) Reassembly

Reassembly procedures should be followed in the reverse order. Note the following points.

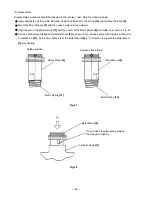

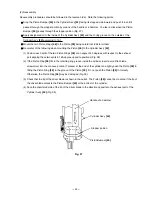

Drop the Piston Bumper

[40]

in the Cylinder Ass'y

[42]

facing its stepped side inward and push it in until it

passes through the stopper portion by means of the handle of a hammer. You feel a click when the Piston

Bumper

[40]

passes through the stopper portion (Fig. 37).

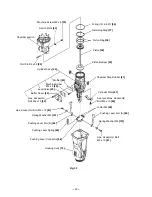

Apply designated oil to the inside of the Cylinder Ass'y

[42]

and the O-ring groove on the outside of the

Cylinder Ass'y

[42]

according to 10-1.

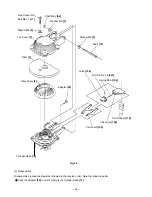

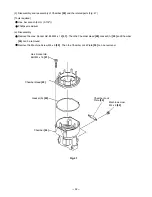

Mount the two Piston Rings

[38]

to the Piston

[39]

being careful not to deform them.

Be careful of the following when mounting the Piston

[39]

to the Cylinder Ass'y

[42]

.

(1) Position each split of the two Piston Rings

[38]

at an angle of 90 degrees with respect to the exhaust

port aligning these two splits in 180-degree opposite positions (Fig. 38).

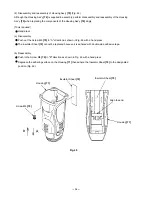

(2) If the Piston Ring

[38]

fits in the retaining ring groove inside the cylinder, insert a small flat-blade

screwdriver into the concave portion (7 places) at the end of the cylinder and lightly push the Piston

[39]

in

fitting the Piston Ring

[38]

in the groove of the Piston

[39]

. Do not push the Piston

[39]

in forcedly.

Otherwise, the Piston Ring

[38]

may be damaged (Fig. 39).

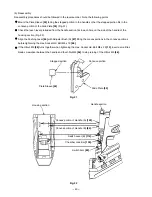

(3) Check that the tip of the driver blade is shown in the outlet. The Piston

[39]

cannot be mounted if the tip of

the driver blade contacts the Piston Bumper

[40]

or the bottom of the cylinder.

(4) Face the chamfered side of the tip of the driver blade in the direction opposite to the exhaust port of the

Cylinder Ass'y

[42]

(Fig. 39).

Cylinder Ass'y

[42]

Handle of a hammer

Piston Bumper

[40]

Stopper portion

Fig. 37

Содержание NR 90GC

Страница 25: ... 22 Fan Clean this area especially Spark plug cable Spark plug Fig 18 ...

Страница 33: ... 30 Handle B 84 Grease application areas Plunger of the fan switch Plunger of the trigger switch Fig 22 ...

Страница 69: ... 66 Fig 58 Lock Bar Spring 102 Fig 59 Ring Tension Plate 113 Switch Lever B 114 ...

Страница 78: ......