“B” Group: Fine Tuning Functions

Configur

ing

Dr

iv

e P

a

ra

m

e

ters

3–24

Electronic Thermal Overload Alarm Setting

The thermal overload detection protects the

inverter and motor from overheating due to

an excessive load. It uses a current/inverse

time curve to determine the trip point.

First, use B_13 to select the torque charac-

teristic that matches your load. This allows

the inverter to utilize the best thermal

overload characteristic for your application.

The torque developed in a motor is directly

proportional to the current in the windings,

which is also proportional to the heat generated (and temperature, over time). Therefore,

you must set the thermal overload threshold in terms of current (amperes) for parameter

B_12. The range is 50% to 120% of the rated current for each inverter model. If the

current exceeds the level you specify, the inverter will trip and log an event (error E05) in

the history table. The inverter turns the motor output OFF when tripped.

WARNING:

When parameter B_12, level of electronic thermal setting, is set to device

FLA rating (Full Load Ampere nameplate rating), the device provides solid state motor

overload protection at 115% of device FLA or equivalent. Parameter B_12, level of

electronic thermal setting, is a variable parameter.

NOTE:

For inverter models 005NFE, 011NFE, and 030HFE, the thermal value is less

than the rated amperes (is the same as models 004NFE, 007NFE, and 040HFE respec-

tively). Therefore, be sure to set the electronic thermal overload according to the actual

motor driven by the particular inverter.

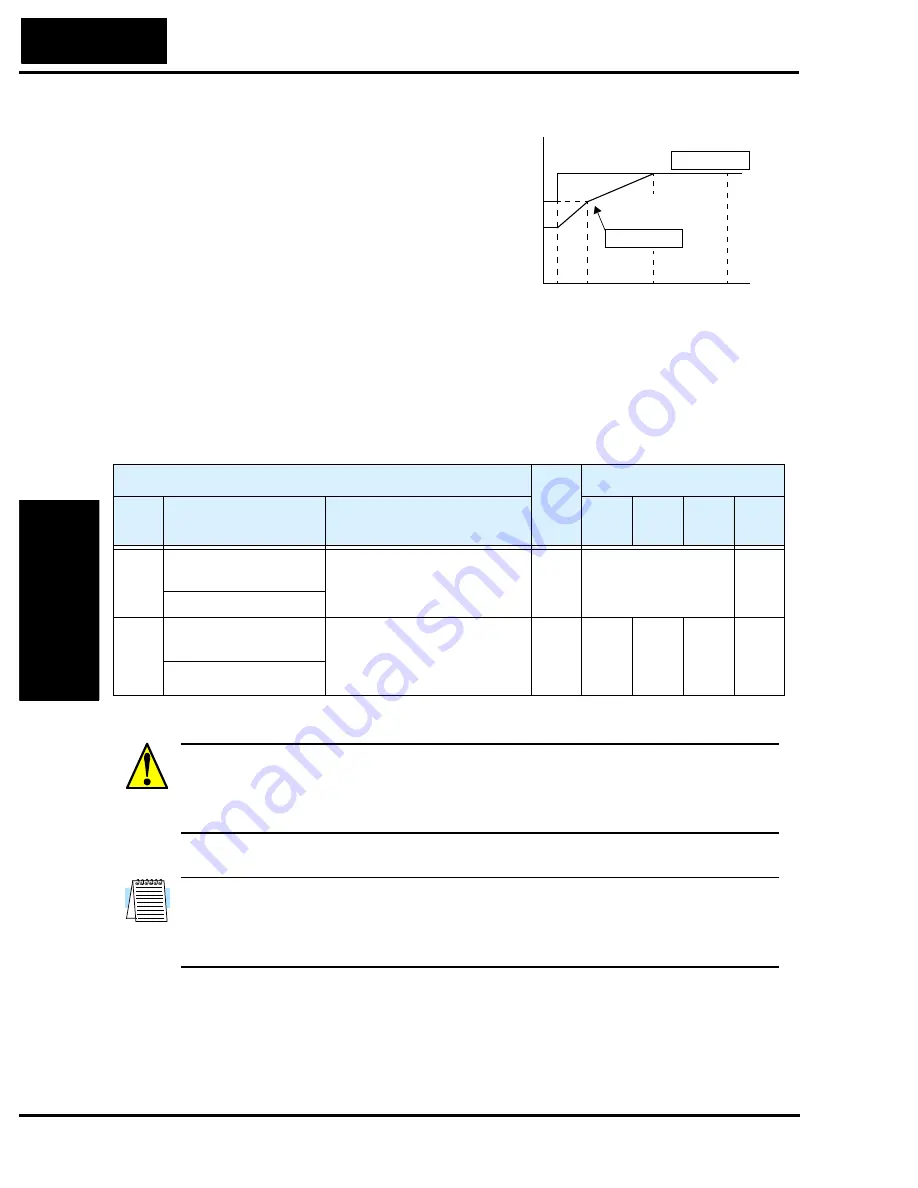

Output frequency

Constant torque

Reduced

torque

B_13 = 01

B_13 = 00

Torque

5

20

60

120

Hz

100%

80%

60%

0

“B” Function

Run

Mode

Edit

Defaults

Func.

Code

Name /

SRW Display

Description

–FE

(CE)

–FU

(UL)

–FR

(Jpn)

Units

B_12 Level of electronic

thermal setting

Set a level between 50% and

120% for the rated inverter

current.

✘

Rated current for each

inverter model

*See note

%

E-THM LVL 03.00A

B_13 Electronic thermal

characteristic

Select from two curves, option

codes:

00 ...Reduced torque

01 ...Constant torque

✘

01

01

00

—

E-THM CHAR CRT

Содержание L100 Series

Страница 145: ...Inverter System Accessories In This Chapter page Introduction 2 Component Descriptions 3 Dynamic Braking 5 5 ...

Страница 168: ...Glossary and Bibliography In This Appendix page Glossary 2 Bibliography 8 A ...

Страница 176: ...Drive Parameter Settings Tables In This Appendix page Introduction 2 Parameter Settings for Keypad Entry 2 B ...

Страница 183: ...CE EMC Installation Guidelines In This Appendix page CE EMC Installation Guidelines 2 Hitachi EMC Recommendations 6 C ...

Страница 186: ...CE EMC Installation Guidelines Appendix C C 4 L1 L2 L3 PE M 3 L100 inverter with footprint type filter ...

Страница 187: ...L100 Inverter Appendix C C 5 L1 L2 L3 PE L100 inverter with book type filter M 3 ...