--- 8 ---

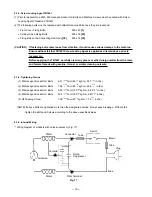

Instruct the customer to check the amount of oil periodically by holding the tool upright, as illustrated below, and

observing the oil level in the Oil Gauge. When the oil level drops to a point approximately 3 mm (7/64") or less

from the bottom of the Oil Gauge, remove the Oil Gauge and replenish the oil.

Fig. 2

Oil Gauge

Hold the tool

upright, and

check the amount

of oil.

3 mm (7/64")

Replenish oil when level

is approx. 3 mm (7/64") or less

from bottom of Oil Gauge.

Under average operating conditions, approximately 3 cc of oil will be consumed per hour of operation. The

standard accessory oil feeder contains 120 cc of oil; when it is added to the oil tank, the oil tank will be filled with

approximately 130 cc of oil. When it becomes necessary to replenish the oil, the customer should be cautioned to

use Shell Omala Oil #150 without fail. To ensure that the appropriate oil is used, the customers should be urged

to purchase and use the optional accessory Hitachi Electric Hammer Oil, Code No. 955009, which is available in

one liter (0.26 gallon) containers.

7-4. Impact Performance at Low Temperatures

When starting the tool early in the morning when the ambient temperature is low or after the tool has not been

used for a long period of time, oil viscosity may be very high and may cause improper or even complete lack of

impact function even though the motor functions properly. In such a case, the customer should be instructed to

continue no-load operation for approximately 5 minutes to allow the tool to warm up. The tool should then

function normally.

Содержание H 65SC

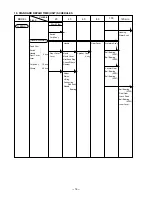

Страница 22: ... 19 Assembly Diagram for H 65SC ...