--- 10 ---

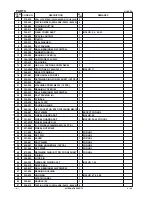

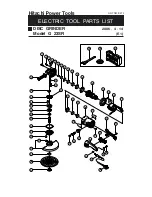

8-2. Reassembly

Put the parts together in the reverse order of disassembly, with the precautions given below.

(1) Apply machine oil to Felt Packing (B)

[24]

<24>

then mount it to the Packing Gland

[27] <27>

to increase the

dust resistance.

(2) Generously lubricate the teeth of the Gear

[20] <20>

and the Pinion

[7] <7>

with grease. Rub grease onto the

teeth with your fingers so that the grease reaches each tooth bottom. Note that under-lubricated Gear

[20]

<20>

and Pinion

[7] <7>

may wear at a faster rate.

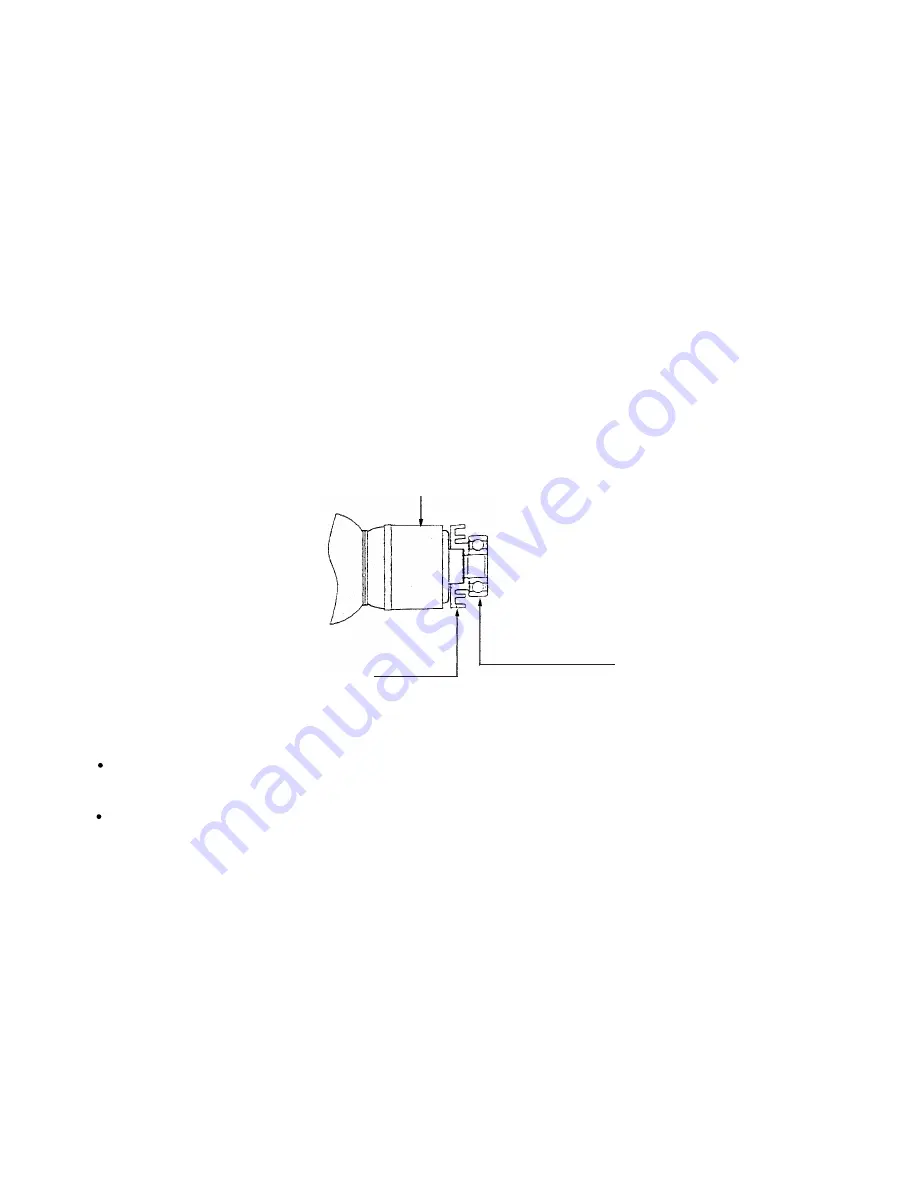

(3) When replacing the Armature

[13] <13>

and the Ball Bearing 6000VVCMPS2L

[38] <46>

on the commutator

side, press inward on the Dust Seal

[37] <45>

while taking care of its direction until the end face of the Dust

Seal

[37] <45>

hits against the butting surface of the Armature

[13] <13>

and make sure that the Dust Seal

[37] <45>

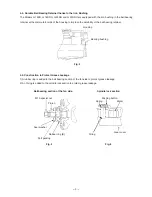

cannot turn freely. (See Fig. 10.)

The Dust Seal

[37] <45>

is an important element for improved dust protection of the Ball Bearing

6000VVCMPS2L

[38] <46>

. Be sure to use a new one at every disassembly work of the Ball Bearing

6000VVCMPS2L

[38] <46>

.

(4) Apply Three Bond TB 1406 Screw Locking Agent to the following screws.

Two Seal Lock Screws (W/Sp. Washer) M5 x 14 (Black)

[1] <1>

which fix Bearing Cover (A)

[12] <12>

in

place.

Four Hex. Socket Hd. Bolt (W/Flange) M5 x 16

[28] <28>

which fix the Packing Gland

[27] <27>

in place.

Fig. 10

Dust seal

Armature

Ball bearing

(6000VVCMPS2L)

Содержание G 18SR

Страница 34: ......