-9-

4. Operation Phenomena to Note in Sales Promotion

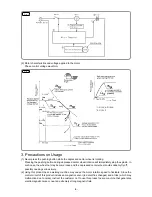

(1) Constant speed control

The rotation speed during operation may fluctuate somewhat depending on the conditions of use and

power source.

(2) Soft-start speed control

Immediately after startup, the rotation speed may fluctuate somewhat depending on the conditions of

use and power source.

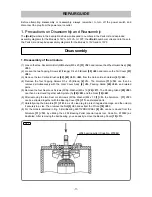

(3) Variable speed control (G 12VA, G 13VA and G 15VA)

For adjusting the number of revolutions, the models above (G 12VA, G 13VA and G 15VA) are

equipped with an electronic infinite-variable-speed drive by which the number of revolutions can be

changed according to specific use. For example, turning and setting the dial scale to 6 increases the

number of revolutions; turning and setting it to 1 decreases the number of revolutions. Before using the

tool, use the dial to set the number of revolutions. Refer to the following table as a rough guide. Be

careful not to turn the dial scale to any setting value below 1 or above 6.

Immediately after shifting gear in the tool, the rotation speed may fluctuate somewhat depending on the

conditions of use and power source.

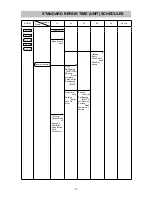

Dial

Use

Tools

1

Polishing, finishing

2

3

4

Removal of paint or other coating

Removal of rust

Removal of burrs

Radial grinding disc

Sanding disc

5

Grinding

Depressed center wheel

6

Rough grinding

Cutting

Depressed center wheel

Diamond wheel

(4) Overload protection control

(a) Overload protection control tends to be easily actuated by certain types of work. Applying excessive

pressure on the tool during cutting or similar heavy-duty operation will actuate overload protection

control and automatically stop the motor. This is because overload protection control detects the

increased flow of current caused by excessive pressure on the tool, and automatically turns off the

motor to protect it against possible overload burnout. The customer should be advised that the

Models G 12VA, G 13VA, G 13YF, G 15VA and G 15YF are specifically designed to perform more

efficiently and faster with considerably less pressure applied than that required for conventional disc

grinders, and that skillful use of the tools with minimal applied pressure will avoid actuating overload

protection control. The customer should also be advised, however, that the overload protection

control feature cannot always prevent overload motor burnout under all possible use conditions.

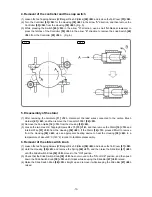

(b) Instruct the customer to immediately turn off the main switch in case overload protection control is

actuated, separate the tool attached to the grinder from the workpiece, turn on the main switch, wait

until the rotation speed increases to normal speed, and then resume work. Also advise the customer

that overload protection control will quickly reactuate even under a slight load if the customer

resumes work before the rotation speed increases to the normal level.

(c) When beginning operation, note that you may inadvertently turn on the switch immediately after

pressing the depressed center wheel or cut-off wheel against the workpiece before the tool reaches

full rotation speed. (This will actuate overload protection control. Therefore, strongly recommend that

the customer never turn the switch on with the depressed center wheel in contact with the workpiece

or press the wheel against the workpiece when beginning operation until normal rotation speed has

been attained.)