--- 12 ---

Slip clutch mechanism

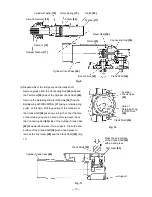

The slip clutch mechanism is described below with reference to Fig. 5. The bevel pinion and the gear holder

are coupled together by the key and press-fitting. Spring (C) and needle pins are housed in elongated

grooves of the gear holder. The needle pin is pressed against the inner face of second gear by spring (C) to

allow idle rotation of the second gear relative to the gear holder. When an excess torque is exerted on the

bevel pinion shaft, the needle pin is raised upon the projection of the second gear against the load of spring

(C) to allow idle rotation of the second gear. With the arrangement, the clutch slips when an excessive torque

is applied to the working tool as when the drill bit contacts steel bar/wire in the concrete, protecting the

operator from unexpected motion of the side handle.

Bevel pinion

Needle pin

Bevel pinion

Gear holder

Gear holder

Second gear

Key

Spring (C)

Gear holder groove

Fig. 5

Cross section A - A

A lever-type retainer is employed to permit easy one-touch

mounting and removal of drill bits, bull points, etc.

As illustrated in Fig. 6, pull the knob in the direction indicated

by arrow a , and turn it 90˚ counterclockwise (arrow b

direction) to align it with the alignment mark on the front

cover. Insert the tool shank fully into the spline hole in the

front cover, and return the knob to its original position. The

tool is then securely attached.

Tool holder

Knob

Alignment mark

Front cover

Fig. 6

Handle and side handle

The handle section is of a two-layer structure. The base is made of glassfiber-reinforced plastic and the

outside layer is soft resin. They are molded in one piece.

The side handle also has a two-layer structure. The base is made of glassfiber-reinforced plastic base with a

steel nut and the outside layer is soft resin. They are molded in one piece. The newly designed handle and

side handle structure ensures more comfortable grip for improved operability.

Tool

A

A

Содержание DH 40FR

Страница 30: ......