--- 14 ---

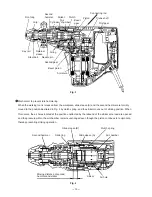

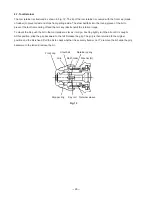

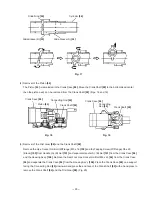

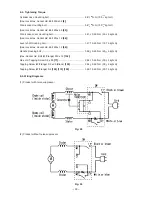

Striker

Second

hammer

Cylinder

Grip

Front cap

Armature

Bevel pinion

Second gear

Clutch

Air

chamber

Steel ball

Needle pin

Key rail

Piston

O-ring

Connecting rod

Crank shaft

First gear

Bevel

gear

Fig. 3

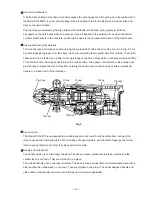

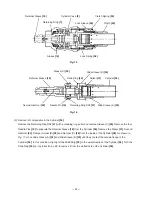

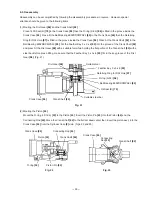

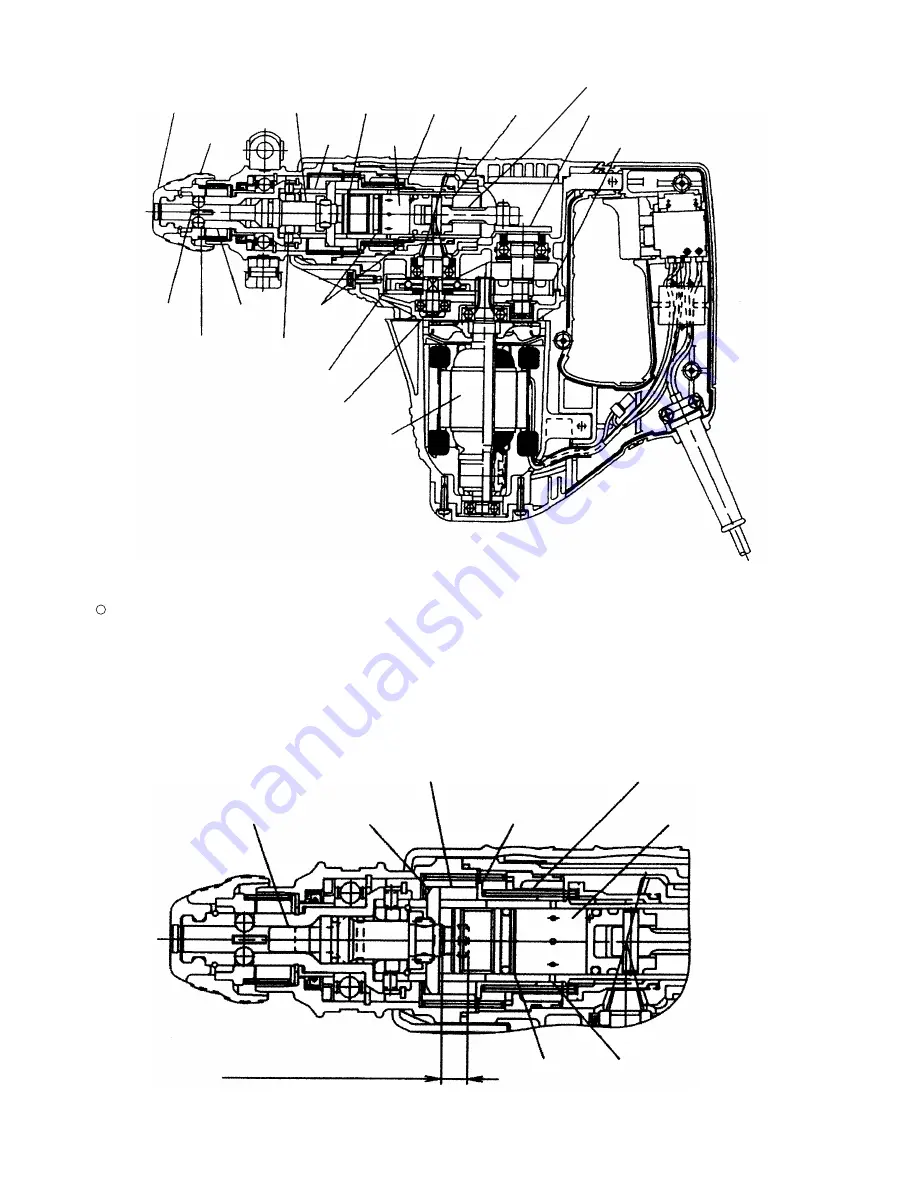

Mechanism to prevent idle hammering

When the working tool is released from the workpiece, slide sleeve (A) and the second hammer are forcibly

moved to the position illustrated in Fig. 4 by clutch spring, and the striker moves out of striking position. When

this occurs, the air holes located at the position unaffected by the rebound of the striker at no load are opened

and the pressure within the air chamber remains unchanged even though the piston continues to reciprocate,

thereby preventing striking operation.

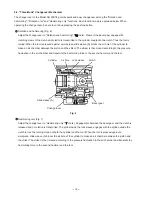

Fig. 4

Retainer

sleeve

Striker

Slide sleeve (A)

Second hammer

Moving distance of second

hammer and striker

Clutch spring

Air chamber

Air hole

Slide sleeve (B)

Slide ring