12

Adjustment has already been made at the time of

shipment from the factory. However, in the unlikely

event of parallelism being faulty, adjust as follows.

(1)

Unfasten only the mounting screws of the saw

cover hinge portion (

Fig. 4

).

(2)

Retract the protective cover into the saw cover.

(3)

Insert wood chip in the rear side of the saw

blade base, and mark the position on the base

(

Fig. 5

).

(4)

Move the marked wood chip to the front of

the base, and turn the parallelism adjustment

screw so that the marking corresponds to the

base side (

Fig. 6

).

(5)

After adjustment, fasten the mounting screws

tightly in place.

NOTE

䡬

Parallelism may be slightly faulty if the cutting

depth is adjusted after parallelism adjustment.

CUTTING PROCEDURES

1. Place the saw body (base) on the lumber, and align

the marked off line with the saw blade by use of the

front scale. When the saw blade is not inclined, the

right-hand side is the reference (

Fig. 7

).

2. Turn ON the switch before the saw blade contacts the

lumber. The switch is turned ON when the trigger is

squeezed, and turned OFF when the trigger is

released.

3. Moving the saw straight at a constant speed will

produce optimum cutting.

CAUTIONS:

䡬

Before starting to saw, confirm that the saw blade

has attained full-speed revolution.

䡬

Should the saw blade be stopped or made an

abnormal noise while operating, promptly turn OFF

the switch.

䡬

Always take care in preventing the power cord from

coming near to the revolving saw blade.

䡬

Using the Circular Saw with the saw blade facing

upwards or sideways is very hazardous. Such

uncommon applications should be avoided.

䡬

When cutting material, always wear eye protection.

䡬

When finished a job, disconnect the plug from the

receptacle.

MOUNTING AND DISMOUNTING THE SAW

BLADE

CAUTION:

To avoid serious accident, ensure that the switch is in

the OFF position, and the power source is

disconnected.

1. Dismounting the saw blade

(1) Set the cutting depth to maximum and place the

circular saw on a stable place. (

Fig. 8

)

(2) Keeping the lock lever depressed, carefully turn the

hexagonal-head bolt with the box wrench.

(3) When the saw shaft is fixed, turn the wrench

counterclockwise to remove bolt and washer (B).

(4) While gripping the lower guard knob, retract the

lower guard into the saw cover and take out the saw

blade.

2. Mounting the saw blade

(1) Install the saw blade in the reverse order to removal.

(2) Wipe off the swarf from the spindle, washer, etc.

(3) As shown in

Fig. 9

, the side of Washer (A) with a

projected center the same diameter as the inner

diameter of the saw blade and the concave side of

Washer (B) must be fitted to the saw blade sides.

* Washer (A) is supplied for 2 types of saw blades

with the inner diameters of 20 mm and 30 mm.

(When buying the Circular Saw, one type of washer

(A) is supplied.)

In case the inner diameter of your saw blade does

not correspond to that of Washer (A), please contact

the shop where you purchased the Circular Saw.

(4) The saw blade should be installed so that the arrow

in the saw blade is aligned with the arrow on the saw

cover.

(5) Using the fingers, tighten the hexagonal-head bolt

retaining the saw blade as much as possible. Then

depress the lock lever, lock the spindle, and

thoroughly tighten the bolt.

CAUTIONS:

䡬

If a wrench other than the one supplied is used, the

bolt cannot be tightened correctly. Always use the

supplied wrench.

䡬

Before connecting the power plug, check that the

lock lever is returned to its original position and the

saw blade rotates smoothly.

MAINTENANCE AND INSPECTION

1. Inspecting the saw blade

Since use of a dull saw blade will cause motor

malfunctioning and degraded efficiently, replace with

a new one without delay if abrasion is noted.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure

that they are properly tightened. Should any of the

screws be loose, retighten them immediately. Failure

to do so could result in serious hazard.

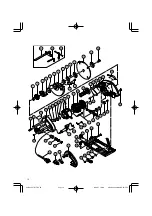

3. Inspecting the carbon brushes (Fig. 10)

The motor employs carbon brushes which are

consumable parts. Since an excessively worn carbon

brush could result in motor trouble, replace the carbon

brushes with new ones which have the same carbon

brush No. shown in the figure when they become

worn to or near the “wear limit”. In addition, always

keep carbon brushes clean and ensure that they slide

freely within the brush holders.

4. Replacing carbon brushes

Disassemble the brush caps with a slotted-head

screwdriver. The carbon brushes can then be easily

removed.

5. Maintenance of the motor

The motor unit winding is the very “heart” of the

power tool. Exercise due care to ensure the winding

does not become damaged and/or wet with oil or

water.

6. Service parts list

A : Item No.

B : Code No.

C : No. Used

D : Remarks

02Eng̲C7MFA̲ChS

09.2.27, 19:06

Page 12

Adobe PageMaker 6.5J/PPC

Содержание C 7MFA

Страница 15: ...14 03Back C7MFA ChS 09 2 27 19 06 Page 14 Adobe PageMaker 6 5J PPC ...

Страница 16: ...15 03Back C7MFA ChS 09 2 27 19 06 Page 15 Adobe PageMaker 6 5J PPC ...

Страница 18: ...17 03Back C7MFA ChS 09 2 27 19 06 Page 17 Adobe PageMaker 6 5J PPC ...

Страница 19: ...18 03Back C7MFA ChS 09 2 27 19 06 Page 18 Adobe PageMaker 6 5J PPC ...